Information injection-pump assembly

BOSCH

9 460 614 531

9460614531

ZEXEL

104745-8271

1047458271

MITSUBISHI

MD334895

md334895

Rating:

Cross reference number

BOSCH

9 460 614 531

9460614531

ZEXEL

104745-8271

1047458271

MITSUBISHI

MD334895

md334895

Zexel num

Bosch num

Firm num

Name

104745-8271

9 460 614 531

MD334895 MITSUBISHI

INJECTION-PUMP ASSEMBLY

4D56 K

4D56 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

52.1

53.1

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

62.6

62.1

63.1

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

76.6

76.1

77.1

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

51.6

53.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

62.6

61.6

63.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

77

74.5

79.5

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

76.6

75.6

77.6

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_08

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

65

62.5

67.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

24.9

30.9

Difference in delivery

mm3/st.

8.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2950

2950

2950

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

22.9

32.9

Difference in delivery

mm3/st.

9

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

19.4

17.9

20.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

19.4

17.4

21.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

8

Oil temperature

degC

50

48

52

Boost compensator adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7.7

7.7

7.7

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

9.6

9.6

9.6

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

85

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

85

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

549

520

578

Pressure

kgf/cm2

5.6

5.3

5.9

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

1.2

0.6

1.8

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.5

2.9

4.1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.2

5

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

5.6

5

6.2

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

7.8

7.2

8.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

48

47.5

48.5

Timer stroke TA

mm

3.9

3.7

4.1

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

48

47

49

Timer stroke TA

mm

3.9

3.5

4.3

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

32

31

33

Timer stroke TA

mm

2.5

1.9

3.1

Timer stroke variation dT

mm

2.1

2.1

2.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

BCS stroke

mm

5.7

5.5

5.9

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

42

37

47

Test data Ex:

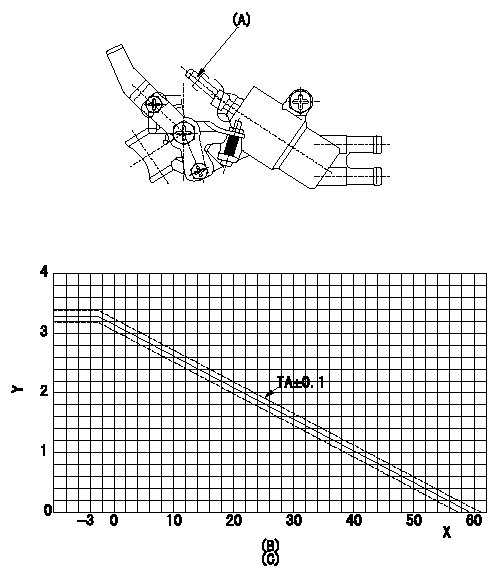

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the following graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(B): Timer stroke TA (mm):

----------

----------

(C)=TA=-0.0526t+3.14(-3<=t)

----------

----------

(C)=TA=-0.0526t+3.14(-3<=t)

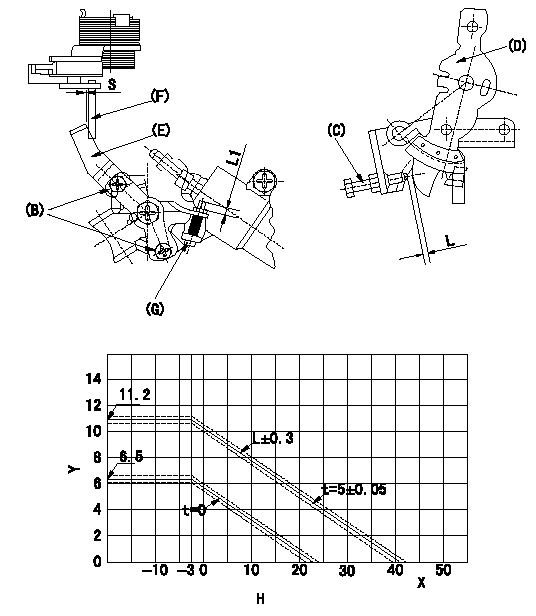

0000001901 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L determined from the graph below between the control lever (D) and the idling stopper bolt (C).

(2)Insert a shim S between the W-FICD lever (E) and the control lever (F). Adjust the W-FICD lever (E) so that it contacts the control lever (F) and fix it using bolt (B).

TT

Note:

a) The temperature of wax at the time of adjustment must not exceed a.

b) After completion of the adjustment, confirm that allowance for adjustment of the screw (G) is at least L1.

Y:Control lever L mm

X:Temperature t (deg C)

H:Control lever gap: L (mm)

----------

L=L+-0.05mm S=5+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

S=5mm L1=3mm H=L=-0.256t+10.39(-3<=tdegC)(S=5+-0.05mm)

----------

L=L+-0.05mm S=5+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

S=5mm L1=3mm H=L=-0.256t+10.39(-3<=tdegC)(S=5+-0.05mm)

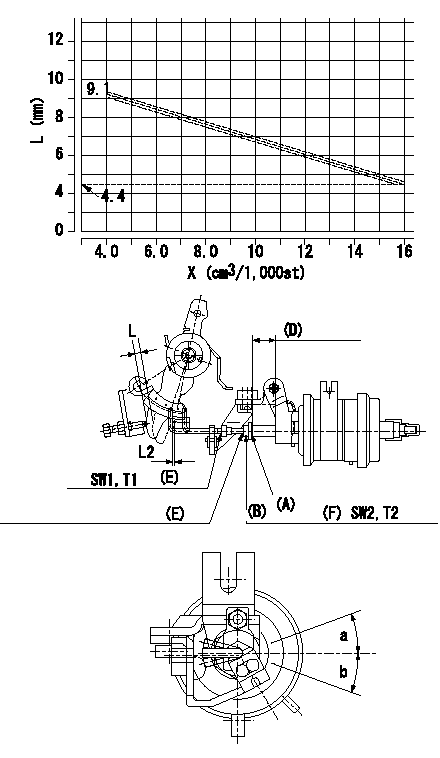

0000002001 V-FICD ADJUSTMENT

Adjustment of the two stage actuator (FICD).

(C): Stroke adjusting nut

(D): Actuator stroke

(E): Rod position adjusting nut

(F): Stroke adjusting nut

X:Injection quantity

Y:Shim thickness: L

1. Selecting the shim for adjusting the actuator.

(1)Measure the injection quantity at N by inserting the shim L1 between the control lever and the idling stopper bolt.

(2)Select the thickness (L) of the shim for adjusting the actuator using the following formula (refer to the graph.).

Calculation: L

2. Adjustment of the actuator

(1)Mount the actuator to the injection pump.

(2)Position the control lever at the idling position.

(3)Adjust with the nut (D) so that the space between the control lever and the rod becomes L2.

(4)Insert the shim (L) determined above between the control lever and the idling stopper bolt.

(5)Adjust the position of the screw (A) so that the actuator can make its full stroke (Reference value: approx. L3) and fix with the nut (B).

(6)Allowable angle in adjusting the position of the rod: c

----------

N=900r/min L1=6.2mm L:L+-0.1=-0.39167Q+10.667(4.0<=Q<=16.0cm3/1,000st) L2=1+1mm L3=9.6mm c=+-20deg

----------

L2=1+1mm SW1=SW7 T1=1.4~2.0N-m{0.14~0.2kgf-m} SW2=SW8 T2=3.5~5.0N-m{0.35~0.5kgf-m} a=20deg b=20deg

----------

N=900r/min L1=6.2mm L:L+-0.1=-0.39167Q+10.667(4.0<=Q<=16.0cm3/1,000st) L2=1+1mm L3=9.6mm c=+-20deg

----------

L2=1+1mm SW1=SW7 T1=1.4~2.0N-m{0.14~0.2kgf-m} SW2=SW8 T2=3.5~5.0N-m{0.35~0.5kgf-m} a=20deg b=20deg

Information:

The troubleshooting chart provides a definite sequence to be followed for a logical procedure to determine the frequency and amplitude of vibration so that the source of the vibration can be located and corrected.1. The customer must be asked questions to determine whether his complaint is valid, or whether his diagnosis of the actual problem is correct.Some of the questions that must be asked are as follows: a. What components are vibrating?b. In what speed range does this vibration become excessive?c. Does clutch operation affect the vibration?d. What is the history of the problem?2. Run the engine through the idle speed range and note all vibrating components. Look for any loose or broken mounts, brackets, and fasteners. Repair and tighten any fixtures.3. Check idle speed range with clutch disengaged. If vibrations subside, there is a balance problem with the clutch disc. The clutch disc must be repaired or replaced.4. Further analysis requires the use of a vibration instrument. Any instrument which can accurately measure the displacement of the vibration (usually in mils-inch/1000) and the frequency (cycles per second) will be sufficient. A vibration instrument such as the IRD Mechanalysis Model 320 or an equivalent instrument can be used to analyze vibration.5. Measure vibration of cab components which have the objectionable vibration.Run engine slowly through the speed range and measure vibration with the instrument filter OUT. When peak amplitudes are found, run the engine at the speeds they occur and with the instrument filter IN, find the frequency of the vibration.If the frequency of vibration is 1/2 times of engine rpm (1/2 order), the vibration is caused by a cylinder misfiring. This must be corrected before further vibration analysis is made.If the frequency of vibration is 4 times engine rpm, no corrective action can be taken on the engine because this is the firing frequency of the 3408 engine. The problem is in the cab or chassis resonance.If frequency is some order other than 1/2 or 4th, then further measurements must be made on the engine.6. Measurements taken on the engine must be made perpendicular to the crankshaft at the front and rear of the engine in vertical and horizontal directions.7. Record all vibrations over 4.0 mils and the engine rpm at which it occurs (100 rpm intervals are sufficient) with instrument filter OUT. Note any sudden increase and decrease in amplitudes. These occur in resonant speed ranges.If no amplitudes exceed 4.0 mils, the engine is within Caterpillar Specs.If amplitudes exceed 4.0 mils, the vibrations must be measured with the instrument filter IN to obtain the frequency of the vibrations.8. Run the engine at high idle. With the instrument filter IN, check the frequency range and record any amplitudes over 4.0 mils and the corresponding frequency. Analysis of vibrations for the possible causes is done by identifying the frequency of the vibration and where on the engine it is the greatest magnitude. Make reference to Special Instruction, TROUBLESHOOTING ENGINE VIBRATION IN VEHICULAR EQUIPMENT, Form No. SEHS7914 for additional information

Have questions with 104745-8271?

Group cross 104745-8271 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

104745-8271

9 460 614 531

MD334895

INJECTION-PUMP ASSEMBLY

4D56

4D56