Information injection-pump assembly

BOSCH

9 460 613 001

9460613001

ZEXEL

104745-4210

1047454210

NISSAN-DIESEL

1670020N05

1670020n05

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104745-4210 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104645-4210 |

| 3. | NUMBER PLATE | 146954-3400 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1121 |

| 8. | Nozzle and Holder | 16600-43G03 |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8{100} |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1130 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2320 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6220 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-1800 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-2120 | HYDRAULIC HEAD |

| 50. | [1] | 146401-2120 | HYDRAULIC HEAD |

| 50. | [1] | 146401-2120 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY VE4 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146501-2120 | GOVERNOR COVER |

| 67/1. | [1] | 146508-7721 | GOVERNOR COVER |

| 67/2. | [1] | 146515-2820 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146537-6120 | CONTROL LEVER |

| 67/6. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/7. | [1] | 146621-0700 | UNION NUT |

| 67/13. | [1] | 146621-3100 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-6400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/18. | [1] | 146587-8000 | COILED SPRING |

| 67/19. | [1] | 146541-3000 | BUSHING |

| 67/21. | [1] | 146587-9900 | COILED SPRING |

| 67/22. | [1] | 146541-3100 | SLOTTED WASHER |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/89. | [1] | 146541-4900 | PLAIN WASHER |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 95. | [1] | 146551-9620 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146975-2500 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-0800 | PLUG L3.30 |

| 117/1. | [1] | 146577-0900 | PLUG L3.50 |

| 117/1. | [1] | 146577-1000 | PLUG L3.70 |

| 117/1. | [1] | 146577-1100 | PLUG L3.90 |

| 117/1. | [1] | 146577-1200 | PLUG L4.10 |

| 117/1. | [1] | 146577-1300 | PLUG L4.30 |

| 117/1. | [1] | 146577-1400 | PLUG L4.50 |

| 117/1. | [1] | 146577-1500 | PLUG L4.70 |

| 117/1. | [1] | 146577-5700 | PLUG L3.2 |

| 117/1. | [1] | 146577-5800 | PLUG L3.4 |

| 117/1. | [1] | 146577-5900 | PLUG L3.6 |

| 117/1. | [1] | 146577-6000 | PLUG L3.8 |

| 117/1. | [1] | 146577-6100 | PLUG L4.0 |

| 117/1. | [1] | 146577-6200 | PLUG L4.2 |

| 117/1. | [1] | 146577-6300 | PLUG L4.4 |

| 117/1. | [1] | 146577-6400 | PLUG L4.6 |

| 117/1. | [1] | 146577-6500 | PLUG L4.8 |

| 120. | [1] | 146579-6020 | RETAINING PIN |

| 122. | [1] | 146580-0400 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE STAMP 02 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-3920 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-1000 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 221. | [1] | 146925-7020 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 230. | [1] | 146925-8320 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-6420 | WIRE |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 020118-1440 | BLEEDER SCREW |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 247. | [1] | 146605-9120 | PIPE |

| 251. | [1] | 014010-8140 | PLAIN WASHER |

| 310. | [1] | 146673-5823 | POTENTCIOMETER |

| 310/2. | [1] | 146925-8220 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/5. | [1] | 146620-2900 | FLAT-HEAD SCREW |

| 310/6. | [1] | 146621-0500 | UNION NUT |

| 310/7. | [1] | 146614-2300 | JOINT CONNECTION |

| 310/8. | [1] | 139006-5700 | BLEEDER SCREW |

| 310/9. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 800S. | [1] | 146009-9220 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146684-1510 | POTENTCIOMETER |

| 906. | [1] | 146954-3400 | NAMEPLATE |

Include in #2:

104745-4210

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 001

9460613001

ZEXEL

104745-4210

1047454210

NISSAN-DIESEL

1670020N05

1670020n05

Zexel num

Bosch num

Firm num

Name

104745-4210

9 460 613 001

1670020N05 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

K 11CJ INJECTION PUMP ASSY VE4 VE

K 11CJ INJECTION PUMP ASSY VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

51.9

51.4

52.4

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

52.5

50.5

54.5

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

51.9

50.9

52.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

42.6

40.5

44.7

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

32.8

30.8

34.8

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

32.8

29.8

35.8

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_04

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10

5.5

14.5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

7.3

5.3

9.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

7.3

4.8

9.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

45

80

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

390

260

520

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

490

360

620

Oil temperature

degC

50

48

52

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

750

750

750

Pressure with S/T ON

kPa

402

363

441

Pressure with S/T ON

kgf/cm2

4.1

3.7

4.5

Pressure with S/T OFF

kPa

294

274

314

Pressure with S/T OFF

kgf/cm2

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

750

750

750

Pressure with S/T OFF

kPa

294

265

323

Pressure with S/T OFF

kgf/cm2

3

2.7

3.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1100

1100

1100

Pressure with S/T OFF

kPa

373

334

412

Pressure with S/T OFF

kgf/cm2

3.8

3.4

4.2

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1700

1700

1700

Pressure with S/T OFF

kPa

481

432

530

Pressure with S/T OFF

kgf/cm2

4.9

4.4

5.4

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

750

750

750

Timer stroke with S/T ON

mm

2.8

2.4

3.2

Timer stroke with S/T OFF

mm

1.2

1

1.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

750

750

750

Timer stroke with S/T ON

mm

2.8

2.2

3.4

Timer stroke with S/T OFF

mm

1.2

0.8

1.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.2

3.4

5

Timer stroke with S/T OFF

mm

2.5

1.9

3.1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T ON

mm

6.5

5.7

7.3

Timer stroke with S/T OFF

mm

4.9

4.2

5.6

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2550

2550

2550

Timer stroke with S/T OFF

mm

7.4

6.7

8

Oil temperature

degC

55

52

58

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

25

23

27

Control lever angle beta

deg.

36

31

41

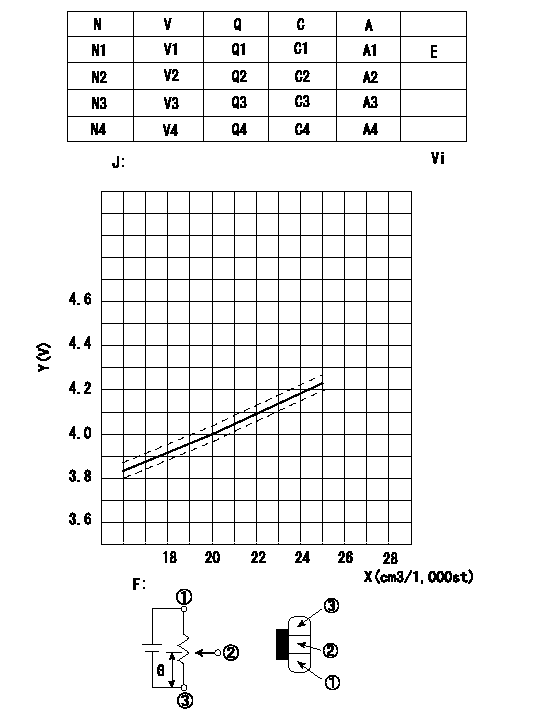

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Measure the injection quantity with the control lever a from the idle position (equal to shim thickness L1) at pump speed N5. Install the potentiometer so that injection quantity and output voltage correspond as shown in the graph.

J = formula

A = shim thickness

C = control lever angle

E = adjusting point

Vi = applied voltage

V = potentiometer voltage

X = injection quantity Q

Y = voltage (V)

C2 = idle

C3 = full speed

F = potentiometer circuit diagram

G = output

N = pump speed

Q = injection quantity

1 = black

2 = blue yellow

3 = blue red

----------

N5=750r/min a=9.0deg L1=6.0mm

----------

N1=750r/min N2=-r/min N3=-r/min N4=-r/min V1=4.0V V2=(0.85)V V3=Above 6.0V V4=-V Q1=17.8+-1.8 cm3/1,000st Q2=-cm3/1,000st Q3=-cm3/1,000st Q4=-cm3/1,000st C1=(9.0)deg C2=Idle C3=Full speed C4=- A1=(6.0)mm A2=- A3=- A4=- J=V+-0.03=0.045X+3.197

----------

N5=750r/min a=9.0deg L1=6.0mm

----------

N1=750r/min N2=-r/min N3=-r/min N4=-r/min V1=4.0V V2=(0.85)V V3=Above 6.0V V4=-V Q1=17.8+-1.8 cm3/1,000st Q2=-cm3/1,000st Q3=-cm3/1,000st Q4=-cm3/1,000st C1=(9.0)deg C2=Idle C3=Full speed C4=- A1=(6.0)mm A2=- A3=- A4=- J=V+-0.03=0.045X+3.197

Information:

Image1.1.2

2. Remove existing 215-2705 cap (Image 1.2.1), and replace with new 272-7102 cap, utilizing the existing cap screws (Image 1.2.1). Insure that threads are coated with Thread Lock P/N 9S-3263 or 4C-4030 and torque cap screws to 7(+/-1) Nm.

Image1.2.1

3. Install new 263-2905 switches (Image 1.3.1) into caps insuring that threads are coated with P/N 4C-5598 High temperature Anti-Seize and torque to 16(+/-2) Nm

Image1.3.1

4. Connect new switch to the applicable wiring harness. Install ladder clips as shown (Image 1.4.1), using 0S-1588 Bolts coated with P/N 4C-5598 High Temperature Anti-Seize to replace the top two existing bolts as shown. Torque these bolts to 47 (+/-9) Nm.

Image1.4.1

Image1.4.2

5. IMPORTANT - Tie-wrap new switch wiring to existing solenoid wiring as shown (Images 1.4.1 & 1.4.2), to prevent thermal damage to wiring.

6. Install information films P/N 179-0133 on electrically actuated Air Shut Offs over the existing films on the solenoids as shown in (Image 1.6.1) or install information films for hydraulically actuated Air Shut Offs over the existing films on the valve covers as shown in (Image 1.6.2).

Films in languages other than English are available under the following part numbers:

-Arabic 297-2613

-French 297-2614

-German 297-2615

-Spanish 297-2616

-Portuguese 297-2617

-Russian 297-2618

Image1.6.1

Image1.6.2

Important Notes:

1. If a new switch is to be painted, mask the vent holes around the perimeter of the switch before painting and be sure to remove the masking after the paint dries.

2. Test completed modifications as detailed below for the specific ECM installed on the engine (ADEM 2 or ADEM 3).

OPERATIONAL TEST - ADEM 2 Engine Control Modules ONLY

Note: (For Troubleshooting purposes) The ASO switches are normally closed switches that are in the closed state when the air shutoff valves are latched in the open ("Run") position. If the air shutoff valves are in the closed ("Stop") position, the switch will be in the open state, causing an emergency stop and shutting the engine down. This also prevents the engine from starting.

DO NOT START THE ENGINE! Ensure that the engine control is in the "OFF" position.

1. Ensure that both air shutoff gates are latched in the OPEN position and ensure that both air shutoff switches are connected. Turn on the power to the engine control panel. Both air shutoff gates should remain open. If both air shutoff gates do not remain open, check the wiring for the air shutoff switches.

2. With the power for the engine control panel in the ON position, activate the "EMERGENCY STOP" switch. Both of the air shutoff gates should close. If both air shutoff gates close, proceed to step 3. If both air shutoff gates do not close, check the wiring for the air shutoff switches and check the wiring for the solenoids. Activate the "EMERGENCY STOP" switch again. When both air shutoff gates close, proceed to step 3.

3. Turn the power to the engine control panel to the OFF position. Ensure that the "EMERGENCY STOP" switch is in the RUN position. Latch only the right side air shutoff gate to the OPEN position. Turn the power for the engine control panel to

Have questions with 104745-4210?

Group cross 104745-4210 ZEXEL

Nissan-Diesel

104745-4210

9 460 613 001

1670020N05

INJECTION-PUMP ASSEMBLY