Information injection-pump assembly

ZEXEL

104745-3610

1047453610

Rating:

Cross reference number

ZEXEL

104745-3610

1047453610

Zexel num

Bosch num

Firm num

Name

104745-3610

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

52.1

53.1

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

62.6

62.1

63.1

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

76.6

76.1

77.1

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

51.6

53.6

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

62.6

61.6

63.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

77

74.5

79.5

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

76.6

75.6

77.6

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_08

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

65

62.5

67.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

24.9

30.9

Difference in delivery

mm3/st.

8.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2950

2950

2950

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

22.9

32.9

Difference in delivery

mm3/st.

9

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

19.4

17.9

20.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

19.4

17.4

21.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

8

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

85

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

85

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

549

520

578

Pressure

kgf/cm2

5.6

5.3

5.9

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

1.2

0.6

1.8

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.5

2.9

4.1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.2

5

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

5.6

5

6.2

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

7.8

7.2

8.4

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.9

56.4

57.4

Timer stroke TA

mm

3.9

3.7

4.1

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.9

55.9

57.9

Timer stroke TA

mm

3.9

3.5

4.3

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

43

42

44

Timer stroke TA

mm

2.5

1.9

3.1

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

61

57

65

Control lever angle beta

deg.

42

37

47

Test data Ex:

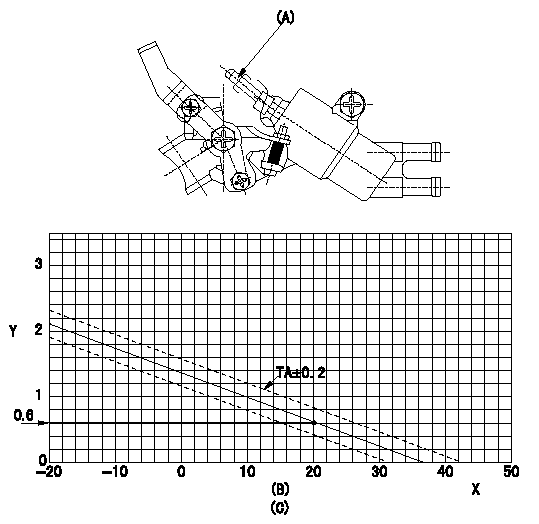

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the following graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(B): Timer stroke TA (mm):

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

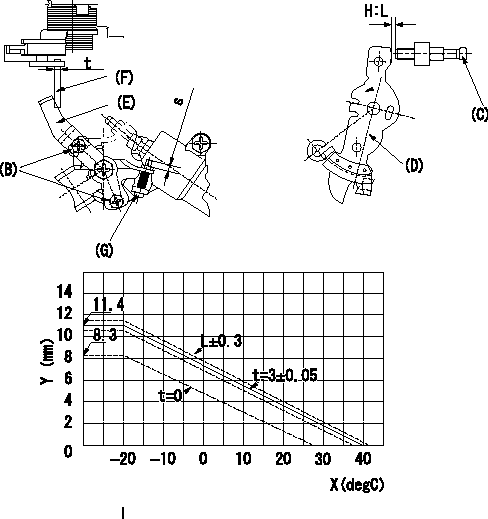

0000001901 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L (determined from the following graph) between the control lever (D) and the idling set screw (C).

(2)Insert a shim t between the W-FICD lever (E) and the control lever (F). Adjust the W-FICD lever (E) so that it contacts the control lever (F) and fix it using bolt (B).

TT

Caution: a) Confirm that the temperature of the wax at adjustment does not exceed e.

b) After completing adjustment, confirm that adjustment allowance of the screw (G) is at least S.

c) After completing adjustment, confirm that the block gauge and shim have been removed.

Y = control lever dimension L (control lever position)

X = temperature X

H = block gauge thickness L

I = graph L - X

----------

L=L+-0.05mm t=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) e=30degC S=3mm

----------

t=3mm S=Above3mm I=L=-0.177X+7.80(-20<=X(degC)) (t=3+-0.05)

----------

L=L+-0.05mm t=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) e=30degC S=3mm

----------

t=3mm S=Above3mm I=L=-0.177X+7.80(-20<=X(degC)) (t=3+-0.05)

Information:

Introduction

The following special instructions must be used to test for a crack in the Diesel Particulate Filter (DPF). Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information that is contained in this document.Required Tools

Table 1

Required Tools

Tool Part Number Part Description Qty

A 380-5200 Tool Kit 1

B 366-7782 Attenuator 1 Testing Procedure

Perform a "Manual Diesel Particulate Filter Regeneration" using the electronic service tool.

After the manual DPF regeneration is complete, operate the engine at 1800 rpm for a MINIMUM of 20 minutes to stabilize the DPF temperatures.Note: The engine must maintain a steady speed for the entire duration of the test.

Hot engine components can cause injury from burns. Before performing maintenance on the engine, allow the engine and the components to cool.

Illustration 1 g02597531

Typical example (1) DPF Outlet Cap (2) Filter Paper (3) Hose Assembly (4) Air Pump

Illustration 2 g03655197

Typical example

Stop the engine. Disconnect harness assembly from both soot antennae. Remove outlet soot antenna (5). Refer to

The following special instructions must be used to test for a crack in the Diesel Particulate Filter (DPF). Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information that is contained in this document.Required Tools

Table 1

Required Tools

Tool Part Number Part Description Qty

A 380-5200 Tool Kit 1

B 366-7782 Attenuator 1 Testing Procedure

Perform a "Manual Diesel Particulate Filter Regeneration" using the electronic service tool.

After the manual DPF regeneration is complete, operate the engine at 1800 rpm for a MINIMUM of 20 minutes to stabilize the DPF temperatures.Note: The engine must maintain a steady speed for the entire duration of the test.

Hot engine components can cause injury from burns. Before performing maintenance on the engine, allow the engine and the components to cool.

Illustration 1 g02597531

Typical example (1) DPF Outlet Cap (2) Filter Paper (3) Hose Assembly (4) Air Pump

Illustration 2 g03655197

Typical example

Stop the engine. Disconnect harness assembly from both soot antennae. Remove outlet soot antenna (5). Refer to

Have questions with 104745-3610?

Group cross 104745-3610 ZEXEL

Mitsubishi

104745-3610

INJECTION-PUMP ASSEMBLY