Information injection-pump assembly

BOSCH

9 460 610 683

9460610683

ZEXEL

104745-3390

1047453390

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104745-3390 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104645-3390 |

| 3. | NUMBER PLATE | 146956-6800 |

| 4. | _ | |

| 5. | CAPSULE | 146620-0120 |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1311 |

| 8. | Nozzle and Holder | MD196607 |

| 9. | Open Pre:MPa(Kqf/cm2) | 14.7{150} |

| 10. | NOZZLE-HOLDER | 105078-0181 |

| 11. | NOZZLE | 105007-1300 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-3520 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6520 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2800 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2900 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2700 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-1900 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0320 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146820-2320 | GOVERNOR COVER |

| 67/1. | [1] | 146508-8221 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 72. | [1] | 146830-7620 | CONTROL LEVER |

| 72B. | [1] | 146830-7720 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146551-6120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-7900 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 120. | [1] | 146579-5320 | RETAINING PIN |

| 122. | [1] | 146580-2300 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 138. | [1] | 146605-8620 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 217. | [1] | 146542-5300 | SLOTTED WASHER |

| 218. | [1] | 146592-2500 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2600 | COILED SPRING |

| 224. | [1] | 139006-4700 | BLEEDER SCREW |

| 229. | [1] | 146928-1220 | BRACKET |

| 230. | [1] | 146629-2120 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 232. | [1] | 146931-3200 | BRACKET |

| 233. | [1] | 146658-9020 | WIRE |

| 234. | [1] | 139006-4800 | BLEEDER SCREW |

| 235. | [1] | 146659-0600 | CLAMPING BAND |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0300 | EYE BOLT |

| 247. | [1] | 146666-0120 | INLET UNION |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 253. | [1] | 139006-4500 | BLEEDER SCREW |

| 275. | [1] | 146612-4800 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW M10P1.5L16 4T |

| 280. | [1] | 146361-7020 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW M6P1L12 |

| 286. | [1] | 020106-3040 | BLEEDER SCREW |

| 287. | [1] | 014010-6140 | PLAIN WASHER D13&6.5T1 |

| 800S. | [1] | 146018-5120 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146620-0120 | CAPSULE |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146956-6800 | NAMEPLATE |

| 910S. | [1] | 146600-4020 | PARTS SET |

| 910S. | [1] | 146600-4020 | PARTS SET |

| 912S. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 913S. | [1] | 146422-0000 | BLEEDER SCREW |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 915S. | [1] | 146658-9020 | WIRE |

| 916S. | [1] | 025804-1610 | WOODRUFF KEY |

Include in #2:

104745-3390

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 610 683

9460610683

ZEXEL

104745-3390

1047453390

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

47.9

47.4

48.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

19.5

16

23

Oil temperature

degC

55

52

58

Injection timing adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

46.4

43.3

49.5

Oil temperature

degC

52

50

54

Injection timing adjustment_04

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

45.2

42.2

48.2

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

47.9

46.9

48.9

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

48

45

51

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

19.5

16.5

22.5

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

12.5

11

14

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Governor adjustment_03

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Governor adjustment_04

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

12.5

10.5

14.5

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

55

95

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

288

552

Oil temperature

degC

48

46

50

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

471

442

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

471

442

500

Pressure

kgf/cm2

4.8

4.5

5.1

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2100

2100

2100

Pressure

kPa

667

638

696

Pressure

kgf/cm2

6.8

6.5

7.1

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.7

4.5

4.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Timer stroke

mm

1.5

0.8

2.2

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

750

750

750

Timer stroke

mm

2.6

2

3.2

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

4.7

4.4

5

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1750

1750

1750

Timer stroke

mm

7

6.3

7.7

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2100

2100

2100

Timer stroke

mm

8.55

8.1

9

Oil temperature

degC

52

50

54

_07

Pump speed

r/min

2200

2200

2200

Timer stroke

mm

8.5

8

9

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.1

34.6

35.6

Timer stroke variation dT

mm

0.5

0.3

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.1

34.1

36.1

Timer stroke variation dT

mm

0.5

0.2

0.8

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

25

23.5

26.5

Timer stroke variation dT

mm

1.2

0.7

1.7

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

55

51

59

Control lever angle beta

deg.

41

36

46

Test data Ex:

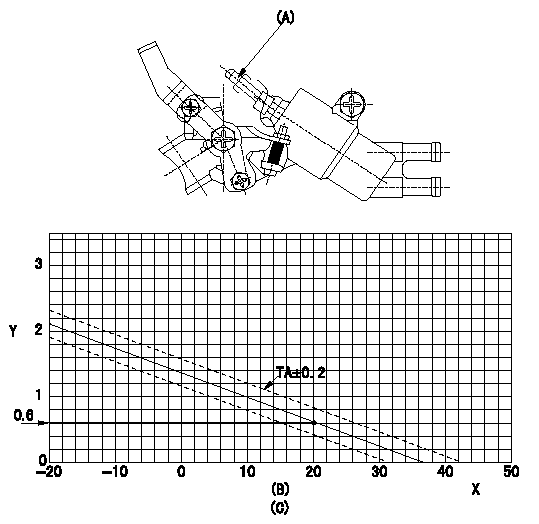

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the following graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(B): Timer stroke TA (mm):

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

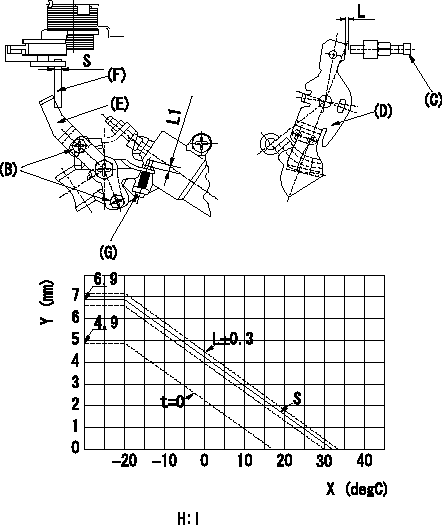

0000001901 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L2 determined from the graph below between the control lever (D) and the idling stopper bolt (C).

(2)Insert a shim S between the W-FICD lever (E) and the control lever (F). Adjust the W-FICD lever (E) so that it contacts the control lever (F) and fix it using bolt (B).

TT

Note:

a) The temperature of wax at the time of adjustment must not exceed a.

b) After completion of the adjustment, confirm that allowance for adjustment of the screw (G) is at least L1.

X:Temperature X (deg C)

Y:Control lever: dimension L (mm) (control lever position)

H:Graph, L - X graph

----------

L2=L+-0.05mm S=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

L1=3++mm S=(3mm) H:L=-0.132X+4.29(-20<=X)(S=3+-0.05)

----------

L2=L+-0.05mm S=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

L1=3++mm S=(3mm) H:L=-0.132X+4.29(-20<=X)(S=3+-0.05)

Information:

Introduction

This document provides information about fuel degradation, which can cause a flow restriction of fuel through the fuel system and premature plugging of the filters. These guidelines should be used to guide service personnel in the use of fuels within diesel engines and covers recognized tests in identifying degredated fuels and best practices in storing fuels.This document can be used as a guide, but it does not provide all the information on all practices and procedures for degraded fuels. This document does not provide all the information for best practices for storing and handling fuels. Refer to Caterpillar Commercial Diesel Engine Fluids Recommendations, SEBU6251 for more information.The Thermal Stability and Oxidation Stability of Fuel

Diesel fuels can deteriorate rapidly for a variety of reasons. When the fuel is stressed and stored for long intervals, degradation and oxidation can occur. Degradation and oxidation are complex chemical changes. These changes lead to deposits or sediment from certain hydrocarbons and traces of naturally occurring nitrogen and sulfur containing compounds in the fuel. Fuel composition and environmental factors influences the process.Diesel fuel is being used as a coolant for high pressure fuel injection systems with high temperature fuel wetted walls. This can stress the fuel in the fuel system. The thermal stress and an increase in recirculation fuel temperature is often responsible for fuel degradation and the formation of gums, resins and sediment, which can cause fuel flow restriction through fuel filters and fuel injection systems.Certain products are often left with the fuel in the fuel system for long periods. This exposes the fuel to oxygen. Complex reactions between the oxygen and the fuel components can generate fuel particulates. The particulates in the fuel system can turn into the sludge that is found in fuel tanks, fuel lines and the fuel filters. This will deteriorate the performance of the fuel system. Degradation also leads to a plugged fuel filter, a restriction to the fuel line and deposit formation in the fuel injection nozzle.Biodiesel and blends of biodiesel have poor thermal stability and oxidation stability compared to petroleum distillate diesel fuels. The use of these biodiesels and blends of biodiesel can accelerate the problems that are addressed in this Special Instruction. Using biodiesel blends above the maximum level approved for the engine is not recommended.Thermal and oxidative degradation of diesel fuel can result in a darkening of fuel color. Fuel color is not necessarily an indication of excessive degradation that will lead to the problems outlined in thisSpecial Instruction, but can be an indicator or degradation If concerns arise about the stability of darkened fuel, the thermal oxidation and oxidative stability tests should be run to confirm actual degradation.Thermal Oxidation Stability

Caterpillar recommends the use of the Accelerated Fuel Oil Stability Test (ASTM D6468). This is a test method that determines the instability of a fuel subjected to a thermal degradation process. This test exposes the fuel to actual operating conditions when the fuel cools the injectors during the engine operation.The test is performed by

This document provides information about fuel degradation, which can cause a flow restriction of fuel through the fuel system and premature plugging of the filters. These guidelines should be used to guide service personnel in the use of fuels within diesel engines and covers recognized tests in identifying degredated fuels and best practices in storing fuels.This document can be used as a guide, but it does not provide all the information on all practices and procedures for degraded fuels. This document does not provide all the information for best practices for storing and handling fuels. Refer to Caterpillar Commercial Diesel Engine Fluids Recommendations, SEBU6251 for more information.The Thermal Stability and Oxidation Stability of Fuel

Diesel fuels can deteriorate rapidly for a variety of reasons. When the fuel is stressed and stored for long intervals, degradation and oxidation can occur. Degradation and oxidation are complex chemical changes. These changes lead to deposits or sediment from certain hydrocarbons and traces of naturally occurring nitrogen and sulfur containing compounds in the fuel. Fuel composition and environmental factors influences the process.Diesel fuel is being used as a coolant for high pressure fuel injection systems with high temperature fuel wetted walls. This can stress the fuel in the fuel system. The thermal stress and an increase in recirculation fuel temperature is often responsible for fuel degradation and the formation of gums, resins and sediment, which can cause fuel flow restriction through fuel filters and fuel injection systems.Certain products are often left with the fuel in the fuel system for long periods. This exposes the fuel to oxygen. Complex reactions between the oxygen and the fuel components can generate fuel particulates. The particulates in the fuel system can turn into the sludge that is found in fuel tanks, fuel lines and the fuel filters. This will deteriorate the performance of the fuel system. Degradation also leads to a plugged fuel filter, a restriction to the fuel line and deposit formation in the fuel injection nozzle.Biodiesel and blends of biodiesel have poor thermal stability and oxidation stability compared to petroleum distillate diesel fuels. The use of these biodiesels and blends of biodiesel can accelerate the problems that are addressed in this Special Instruction. Using biodiesel blends above the maximum level approved for the engine is not recommended.Thermal and oxidative degradation of diesel fuel can result in a darkening of fuel color. Fuel color is not necessarily an indication of excessive degradation that will lead to the problems outlined in thisSpecial Instruction, but can be an indicator or degradation If concerns arise about the stability of darkened fuel, the thermal oxidation and oxidative stability tests should be run to confirm actual degradation.Thermal Oxidation Stability

Caterpillar recommends the use of the Accelerated Fuel Oil Stability Test (ASTM D6468). This is a test method that determines the instability of a fuel subjected to a thermal degradation process. This test exposes the fuel to actual operating conditions when the fuel cools the injectors during the engine operation.The test is performed by