Information injection-pump assembly

BOSCH

F 01G 09W 0E5

f01g09w0e5

ZEXEL

104745-0220

1047450220

MAZDA

WLVX13800

wlvx13800

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104745-0220 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | 146996-8800 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | 146679-4120 |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0720 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0420 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0400 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-5320 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0200 | SLOTTED WASHER |

| 29. | [1] | 146220-4720 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-8420 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2900 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2800 | COMPRESSION SPRING |

| 34C. | [1] | 146312-3000 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-3300 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146403-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-6820 | HYDRAULIC HEAD |

| 50. | [1] | 146403-6820 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-7420 | DELIVERY-VALVE ASSEMBLY VE74 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0220 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146707-3720 | ANEROID CAPSULE |

| 67/1. | [1] | 146806-8620 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/23. | [1] | 146936-6100 | BRACKET |

| 67/24. | [2] | 020306-1640 | BLEEDER SCREW |

| 67/31. | [1] | 146710-0400 | BUSHING |

| 67/32. | [1] | 146602-1800 | PLAIN WASHER |

| 67/33. | [1] | 146716-0200 | UNION NUT |

| 67/34. | [1] | 146713-1000 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET |

| 67/41. | [1] | 146713-3700 | ADJUSTING PIN |

| 67/47. | [1] | 146717-0800 | COILED SPRING |

| 67/49. | [1] | 146721-0700 | COVER |

| 67/54. | [2] | 139006-4500 | BLEEDER SCREW |

| 67/55. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0200 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0400 | CAPSULE |

| 67/64. | [1] | 146936-6600 | BRACKET |

| 67/68. | [1] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 67/70. | [1] | 016520-6010 | O-RING |

| 67/71. | [1] | 146714-0100 | SLOTTED WASHER |

| 67/72. | [1] | 016010-0920 | LOCKING WASHER |

| 67/73. | [1] | 146715-0120 | BELLOWS |

| 67/74/1. | [0] | 146603-3700 | SHIM T0.20 |

| 67/74/1. | [0] | 146603-3800 | SHIM T0.30 |

| 67/74/1. | [0] | 146603-3900 | SHIM T0.50 |

| 67/74/1. | [0] | 146603-4000 | SHIM T0.70 |

| 67/74/1. | [0] | 146603-4100 | SHIM T1.00 |

| 67/74/1. | [0] | 146603-4200 | SHIM T1.50 |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/100. | [1] | 146936-5900 | BRACKET |

| 67/102. | [1] | 146936-5700 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-4100 | THREADED PIN |

| 67/201B. | [1] | 146545-4200 | THREADED PIN |

| 67/201C. | [1] | 146545-4300 | THREADED PIN |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146811-2020 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146831-4320 | CONTROL LEVER |

| 72B. | [1] | 146831-4420 | CONTROL LEVER |

| 72C. | [1] | 146831-7720 | CONTROL LEVER |

| 72D. | [1] | 146831-7820 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146865-6720 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146976-0000 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0920 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-6020 | PULLING ELECTROMAGNET STAMP 60 |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-4901 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 162. | [1] | 146625-8020 | PLATE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 146201-0100 | WOODRUFF KEY |

| 214. | [1] | 146542-7500 | BUSHING |

| 217. | [1] | 146542-2600 | SLOTTED WASHER |

| 218. | [1] | 146592-9800 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-9700 | COILED SPRING |

| 221. | [1] | 146936-5820 | BRACKET |

| 222. | [1] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW |

| 223. | [1] | 146670-9620 | SWITCH |

| 236. | [3] | 139006-4800 | BLEEDER SCREW |

| 236. | [3] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146688-0920 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 407911-1410 | CONTROL UNIT |

| 243. | [1] | 146621-4901 | UNION NUT |

| 244. | [1] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0700 | EYE BOLT |

| 247. | [1] | 146677-3920 | INLET UNION |

| 247. | [1] | 146677-3920 | INLET UNION |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 275. | [1] | 146932-8000 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW |

| 277. | [1] | 146612-8000 | BRACKET |

| 310. | [1] | 146685-8620 | POTENTCIOMETER |

| 310/2. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/3. | [1] | 146620-2900 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146621-0500 | UNION NUT |

| 310/5. | [1] | 146614-2300 | JOINT CONNECTION |

| 310/6. | [1] | 146661-0401 | BOOT |

| 317. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 318. | [1] | 146935-8220 | BRACKET |

| 360. | [1] | 146663-1700 | BUSHING |

| 361. | [1] | 146649-8900 | CAP |

| 362. | [2] | 146620-8403 | BLEEDER SCREW |

| 370. | [1] | 146663-2720 | SPACER RING |

| 800S. | [1] | 146018-7820 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-1520 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0720 | PARTS SET |

| 810S. | [1] | 146600-2420 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 821S. | [1] | 146210-5820 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146685-8810 | POTENTCIOMETER |

| 905. | [1] | 146679-4120 | ACTUATOR |

| 906. | [1] | 146996-8800 | NAMEPLATE |

| 912. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW |

Include in #2:

104745-0220

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 09W 0E5

f01g09w0e5

ZEXEL

104745-0220

1047450220

MAZDA

WLVX13800

wlvx13800

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

(Solenoid timer adjustment condition)

With S/T O-ring; S/T ON. ON

With S/T O-ring; S/T ON. ON

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

45.4

44.9

45.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

40.4

37.4

43.4

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

45.4

44.4

46.4

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

40

36.5

43.5

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2450

2450

2450

Average injection quantity

mm3/st.

15.7

12.7

18.7

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

2450

2450

2450

Average injection quantity

mm3/st.

15.7

5.7

25.7

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

8

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9

8

10

Difference in delivery

mm3/st.

1.7

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

9

7.5

10.5

Difference in delivery

mm3/st.

2.2

Basic

*

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

17

15

19

Difference in delivery

mm3/st.

3

3

3

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

70

55

90

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

70

50

90

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity with S/T ON

cm3/min

420

290

550

Overflow quantity with S/T OFF

cm3/min

460

330

590

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure with S/T ON

kPa

569

530

608

Pressure with S/T ON

kgf/cm2

5.8

5.4

6.2

Pressure with S/T OFF

kPa

471

442

500

Pressure with S/T OFF

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure with S/T OFF

kPa

471

432

510

Pressure with S/T OFF

kgf/cm2

4.8

4.4

5.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

5.7

5.3

6.1

Timer stroke with S/T OFF

mm

4.1

3.9

4.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

500

500

500

Timer stroke with S/T ON

mm

1.8

0.8

2.8

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

5.7

5.1

6.3

Timer stroke with S/T OFF

mm

4.1

3.7

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

2000

2000

2000

Timer stroke with S/T ON

mm

9.2

8.2

10

Timer stroke with S/T OFF

mm

7.6

7

8.2

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.6

35.1

36.1

Timer stroke TA

mm

3.8

3.8

3.8

Timer stroke variation dT

mm

0.3

0.1

0.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.6

34.6

36.6

Timer stroke variation dT

mm

0.3

-0.1

0.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

22.1

20.6

23.6

Timer stroke variation dT

mm

1

0.4

1.6

Oil temperature

degC

50

48

52

0000001501

Pump speed

r/min

1250

1250

1250

Height

m

1460

1460

1460

Atmospheric pressure difference

kPa

-16.7

-18

-15.4

Atmospheric pressure difference

mmHg

-125

-135

-115

Average injection quantity

mm3/st.

42.4

41.9

42.9

Decrease qty

mm3/st.

3

3

3

Decrease rate

%

7

7

7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-5.9

-7.2

-4.6

Atmospheric pressure difference

mmHg

-44

-69

-19

Average injection quantity

mm3/st.

45.4

41.9

46.4

Decrease rate

%

0

0

0

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Atmospheric pressure difference

kPa

-16.7

-18

-15.4

Atmospheric pressure difference

mmHg

-125

-135

-115

Average injection quantity

mm3/st.

42.4

41.4

43.4

Decrease rate

%

7

7

7

Basic

*

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.01

5.91

6.11

MS dimension

mm

1

0.9

1.1

Pre-stroke

mm

0.03

0.01

0.05

Control lever angle alpha

deg.

12.5

8.5

16.5

Control lever angle beta

deg.

40

37

43

Test data Ex:

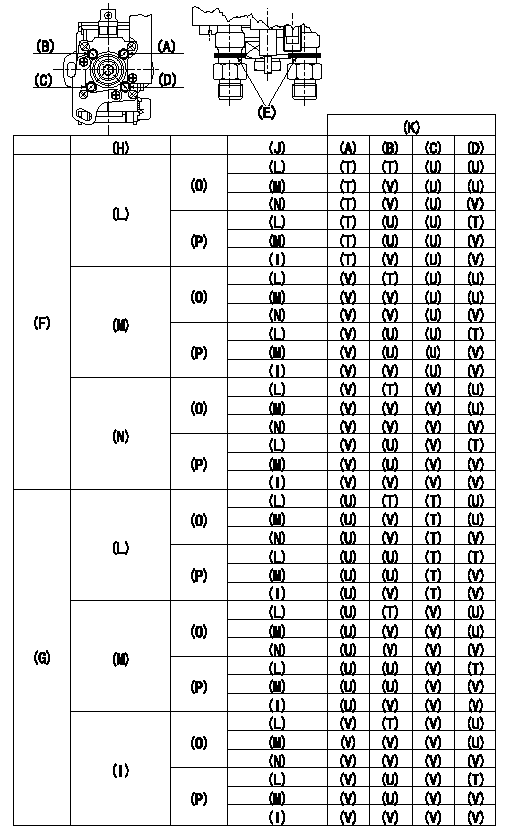

0000001801 CONTROL STANDARD AT IDLING

Standards for idle difference in delivery control

After idle adjustment, measure the idle injection quantities of (A) to (D).

Install the colored rings to the delivery valve holders (A) to (D) in accordance with the table.

(A): A cylinder (B) :B cylinder (C) : C cylinder (D): D cylinder

(E): Collar ring

(F): (A) >= (C)

(G): (C) > (A)

(H): (A) - (C) or (C) - (A)

(I): 0.2, 0.1(mm3/st)

(J): (B) - (D) or (D) - (B)

(K): Ring color

(L): At least 0.6 mm3/st

(M): 0.3, 0.4, 0.5 (mm3/st)

(N): 0.2, 0.1, 0.0 (mm3/st)

(O): (B) >= (D)

(P): (D) > (B)

(T): Yellow

(U): White

(V): Red

----------

----------

----------

----------

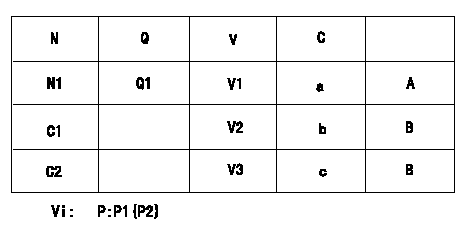

0000001901 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Dummy bolt method

1. Hold the dummy bolt against the control lever at position Np = N1 (r/min) and Q = Q1 (mm3/st) and fix using the lock nut.

2. When adjusting the potentiometer, position the control lever against the dummy bolt and adjust so that the output voltage is V1 (V).

3. After adjustment, remove the dummy bolt and confirm that the potentiometer output voltage at the control lever's idling and full speed positions is as specified above.

Vi:Applied voltage

N:Pump speed (r/min)

V:Output voltage (V)

Q:Injection quantity (mm3/st)

A:Adjusting point

B:Checking point

C:Position of the control lever

C1:Idling

C2:Full speed

P1:Boost pressure (kPa)

P2:Boost pressure (mmHg)

----------

N1=1500r/min Q1=15.2+-1.0mm3/st V1=4.97+-0.03V Vi=10V

----------

N1=1500r/min Q1=15.2+-1.0mm3/st V1=4.97+-0.03V V2=1.73+-0.70V V3=8.40+-0.53V a=18deg b=0deg c=40deg Vi=10V

----------

N1=1500r/min Q1=15.2+-1.0mm3/st V1=4.97+-0.03V Vi=10V

----------

N1=1500r/min Q1=15.2+-1.0mm3/st V1=4.97+-0.03V V2=1.73+-0.70V V3=8.40+-0.53V a=18deg b=0deg c=40deg Vi=10V

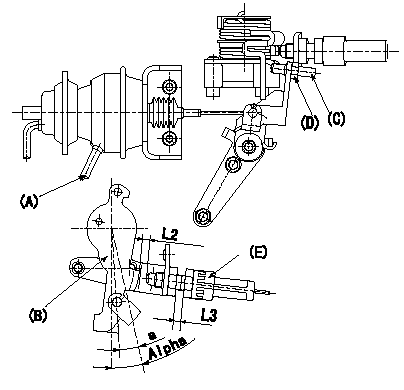

0000002001 WIRE

(1)Wire length confirmation

Accelerator wire (idle ~ full stroke: L1)

(2)Idle switch confirmation

Confirm that the switch is ON at the control lever's idle position.

(3)Adjustment of the two stage actuator

1. Apply negative pressure P1 {P2} to the actuator negative pressure suction port.

2. Under the conditions in 1, adjust using the screw (C) so that the position of the control lever (B) position is a [clearance L2 from the idle switch (E)] and fix using the locknut (D). (Tightening torque T)

3. At idle switch (E) locknut tightening torque T2, gap should be a minimum of L3.

----------

L1=34.2+-3.5mm L2=4.6+-0.5mm L3=2.5mm P1=-66.6kPa P2=-500mmHg a=7.6deg Alpha=12.5+-4deg T1=6~9Nm(0.6~0.9kgfm) T2=12~15Nm(1.2~1.5kgfm)

----------

L2=4.6+-0.5mm L3=2.5mm a=7.6deg Alpha=12.5+-4deg

----------

L1=34.2+-3.5mm L2=4.6+-0.5mm L3=2.5mm P1=-66.6kPa P2=-500mmHg a=7.6deg Alpha=12.5+-4deg T1=6~9Nm(0.6~0.9kgfm) T2=12~15Nm(1.2~1.5kgfm)

----------

L2=4.6+-0.5mm L3=2.5mm a=7.6deg Alpha=12.5+-4deg

Information:

Table 2

Specifications for Pressure Loss

Direct Injection Fuel Systems

Nozzle pressure must not drop below a gauge reading of

3450 kPa (500 psi) during a 5 second time interval.

Nozzle pressure must drop below a gauge reading of

1380 kPa (200 psi) after an additional 25 second time interval. (1)

( 1 ) A gauge reading of 0 kPa (0 psi) is acceptable after the first 5 second time interval has elapsed.

Illustration 3 g00923167

If the fuel nozzle is not within specifications, stop the test and do not use the fuel nozzle.Valve Opening Pressure Test

Slowly increase the pressure until fluid begins to flow from the tip of the fuel nozzle. Record this pressure as the VOP of the fuel nozzle.

Compare the test results to the specifications for the type of fuel nozzle that is being tested. Refer to Table 3, or Table 4.For precombustion chamber fuel systems, use these specifications:

Table 3

Specifications for Valve Opening Pressure

Precombustion Chamber Fuel Systems

2760 to 5170 kPa (400 to 750 psi)

Illustration 4 g00934108

If the VOP is not within specifications, stop the test and do not use the fuel nozzle.For direct injection fuel systems, use these specifications:

Table 4

Specifications for Valve Opening Pressure

Direct Injection Fuel Systems

16500 to 21400 kPa (2400 to 3100 psi)

Illustration 5 g00923174

If the VOP is not within specifications, stop the test and do not use the fuel nozzle.Tip Leakage Test (Direct Injection Fuel Systems)

Note: Fuel nozzles for precombustion chamber fuel systems can not be tested for tip leakage accurately. Do not perform this test on fuel nozzles for a precombustion