Information injection-pump assembly

ZEXEL

104742-7540

1047427540

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

WZCNLXLX Fuel Injection Pump 129671-51950 12967151950 For Yanmar Marine Engine 4JH4-TE 4JH4-HTE

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:129671-51950, 12967151950, YM129671-51950, YM12967151950 || Application:For Yanmar Marine Engine 4JH4-TE 4JH4-HTE || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:129671-51950, 12967151950, YM129671-51950, YM12967151950 || Application:For Yanmar Marine Engine 4JH4-TE 4JH4-HTE || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

ZGZJYBL Fuel Injection Pump For Yanmar Marine Engine 4JH4-TE 4JH4-HTE 129671-51950 12967151950

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:129671-51950, 12967151950, YM129671-51950, YM12967151950 || Application:For Yanmar Marine Engine 4JH4-TE 4JH4-HTE || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

ZGZJYBL Item Name:Fuel Injection Pump || Item Number:129671-51950, 12967151950, YM129671-51950, YM12967151950 || Application:For Yanmar Marine Engine 4JH4-TE 4JH4-HTE || Attention: If you are unsure if the product is suitable for your machine model. In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please carefully check the product image and part number to ensure that it is the product you want. || Tip: If you need any other parts, please contact us - we are a professional sales team and have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104742-7540 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-1920 | DRIVE SHAFT |

| 12/1. | [1] | 146200-1900 | DRIVE SHAFT |

| 12/1. | [1] | 146200-1900 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 12/5. | [1] | 146206-0400 | COILED SPRING |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-9020 | ROLLER SET |

| 24. | [1] | 146303-0400 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0301 | SLOTTED WASHER |

| 29. | [1] | 146220-5020 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-4500 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM |

| 34. | [1] | 146302-4100 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-5200 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146402-5520 | HYDRAULIC HEAD |

| 50. | [1] | 146402-5520 | HYDRAULIC HEAD |

| 50. | [1] | 146402-5520 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET |

| 58. | [4] | 149300-0521 | PRESSURE-CONTROL VALVE |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146704-2420 | COMPENSATOR,MANIFOLD-PRES |

| 67/1. | [1] | 146508-8821 | GOVERNOR COVER |

| 67/2. | [1] | 146515-4820 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146831-7900 | CONTROL LEVER |

| 67/5B. | [1] | 146831-8000 | CONTROL LEVER |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 67/7. | [1] | 013020-6040 | UNION NUT |

| 67/8. | [1] | 146515-1120 | LEVER SHAFT |

| 67/9. | [1] | 146587-4600 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER |

| 67/12. | [1] | 146540-0000 | CONTROL LEVER |

| 67/13. | [1] | 013020-6040 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-4500 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/17. | [1] | 146526-0000 | FLAT-HEAD SCREW |

| 67/18. | [1] | 146587-4000 | COILED SPRING |

| 67/19. | [1] | 146541-0000 | ANGLE PIECE |

| 67/23. | [1] | 146613-1300 | BRACKET |

| 67/24. | [2] | 139006-4700 | BLEEDER SCREW |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/31. | [1] | 146710-0700 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-0700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET |

| 67/39. | [1] | 146620-9500 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET |

| 67/41. | [1] | 146713-4300 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0200 | PLATE |

| 67/43. | [1] | 146715-0300 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-4300 | COILED SPRING |

| 67/48/1. | [1] | 146720-3000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-3100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-3200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-3300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-3400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-3500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-3600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-3700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-3800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-3900 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-4000 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146720-4100 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146720-4200 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146720-4300 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146720-4400 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146720-8900 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146720-9000 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146720-9100 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146720-9200 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146720-9300 | SPACER BUSHING L7.5 |

| 67/48/1. | [1] | 146720-9400 | SPACER BUSHING L7.7 |

| 67/48/1. | [1] | 146720-9500 | SPACER BUSHING L7.9 |

| 67/48/1. | [1] | 146720-9600 | SPACER BUSHING L8.1 |

| 67/48/1. | [1] | 146720-9700 | SPACER BUSHING L8.3 |

| 67/48/1. | [1] | 146720-9800 | SPACER BUSHING L8.5 |

| 67/48/1. | [1] | 146720-9900 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146725-0000 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146725-0100 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146725-0200 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146725-0300 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146725-0400 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146725-0500 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146725-0600 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146725-0700 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146725-0800 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146725-0900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146725-1000 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-1100 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-1200 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-1300 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-1400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-1500 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-1600 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-1700 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-1800 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-1900 | SPACER BUSHING L7.6 |

| 67/48/1. | [1] | 146725-2000 | SPACER BUSHING L7.8 |

| 67/48/1. | [1] | 146725-2100 | SPACER BUSHING L8.0 |

| 67/48/1. | [1] | 146725-2200 | SPACER BUSHING L8.2 |

| 67/48/1. | [1] | 146725-2300 | SPACER BUSHING L8.4 |

| 67/48/1. | [1] | 146725-2400 | SPACER BUSHING L8.6 |

| 67/49. | [1] | 146721-4920 | COVER |

| 67/54. | [4] | 020006-1240 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0300 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/83. | [1] | 146717-4200 | COILED SPRING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 95. | [1] | 146855-1420 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-2600 | PLAIN WASHER |

| 115. | [1] | 146975-4200 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG L5.6 |

| 117/1. | [1] | 146877-4800 | PLUG L5.7 |

| 117/1. | [1] | 146877-4900 | PLUG L5.8 |

| 117/1. | [1] | 146877-5000 | PLUG L5.9 |

| 120. | [1] | 146879-4220 | RETAINING PIN |

| 122. | [1] | 146580-1200 | GOVERNOR SPRING |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-1120 | CAPSULE |

| 130/2. | [1] | 139508-0200 | GASKET |

| 130/3. | [1] | 146422-0300 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-1020 | CONTROL VALVE STAMP 10 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-2620 | OVER FLOW VALVE |

| 230. | [1] | 146936-6300 | BRACKET |

| 231. | [1] | 139006-4700 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 238. | [1] | 146655-0400 | COILED SPRING |

| 240. | [1] | 146650-4520 | PULLING ELECTROMAGNET |

| 240/4. | [1] | 146600-1700 | O-RING |

| 240/7. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-4820 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 280. | [1] | 146361-6320 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW |

| 287. | [1] | 020146-1270 | BLEEDER SCREW |

| 800S. | [1] | 146020-3320 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-1720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0920 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-7320 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 906. | [1] | 146911-0700 | NAMEPLATE |

| 907. | [1] | 029470-4030 | WOODRUFF KEY |

| 908. | [1] | 013121-4140 | UNION NUT |

| 909. | [1] | 029321-4050 | LOCKING WASHER |

Include in #2:

104742-7540

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104742-7540

1047427540

Zexel num

Bosch num

Firm num

Name

104742-7540

INJECTION-PUMP ASSEMBLY

4JH4-TE

4JH4-TE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

110.5

110

111

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

134.2

133.7

134.7

Difference in delivery

mm3/st.

11

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

76.9

76.9

76.9

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.3

32

34.6

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

110.5

108.5

112.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

134.2

132.2

136.2

Difference in delivery

mm3/st.

11

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_06

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

124.1

116.1

132.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1850

1850

1850

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

67

62.5

71.5

Difference in delivery

mm3/st.

8

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

2050

2050

2050

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

1850

1850

1850

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

67

62

72

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

8.5

6.5

10.5

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

8.5

6

11

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

156.1

136.1

176.1

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

156.1

156.1

156.1

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet ON at idling position and reversed operate

Magnet ON at idling position and reversed operate

Speed control lever angle_02

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position and stop lever operate

Magnet OFF at idling position and stop lever operate

0000000901

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Overflow quantity

cm3/min

1380

1150

1610

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

520

491

549

Pressure

kgf/cm2

5.3

5

5.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

422

383

461

Pressure

kgf/cm2

4.3

3.9

4.7

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1400

1400

1400

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

500

461

539

Pressure

kgf/cm2

5.1

4.7

5.5

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

520

481

559

Pressure

kgf/cm2

5.3

4.9

5.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_05

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

539

500

578

Pressure

kgf/cm2

5.5

5.1

5.9

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

0.9

0.7

1.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

0.9

0.5

1.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

1

0.4

1.6

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

Reverse operation (At Normal: OFF, At Stop: ON) V 13 12 14

Reverse operation (At Normal: OFF, At Stop: ON) V 13 12 14

Timing setting

K dimension

mm

3.6

3.5

3.7

KF dimension

mm

6.85

6.75

6.95

MS dimension

mm

0.7

0.6

0.8

BCS stroke

mm

6

5.9

6.1

Pre-stroke

mm

0.2

0.18

0.22

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

42

37

47

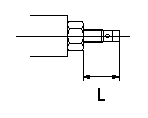

Test data Ex:

0000001801 Temp. adjust full-load screw

Temporary full load screw adjustment

Set the full load screw protrusion at L mm at assembly.

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

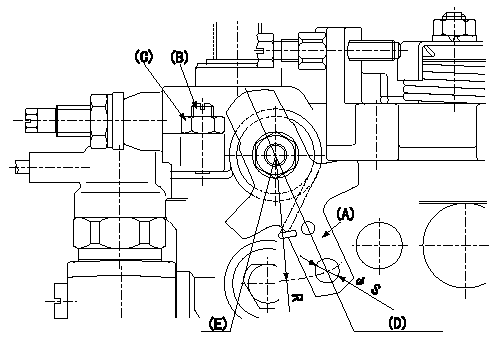

0000001901 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

1. Confirm that the starting injection quantity is within standards at the normal position.

If below the specified lower limit, move the stop lever serrations one tooth and reconfirm.

2. Pull the stop lever (A) to the fuel cut direction at the standard idling speed of N and adjust the screw (B) to the position Q.

Fix nut (C) to the torque T at the position where the clearance between the stop lever and the end of the screw is L mm (the screw is returned 2 turns).

The head of the screw must protrude above the face of the nut. If the head of the screw is below the face of the nut, adjust the clearance between the stop lever A and the end of the screw at Q to L mm or more.

3. If adjustment in item 2 is not possible, move the stop lever installation position 1 tooth.

4. The stop lever's operating force is max. M kg (at R = 35). The stop lever must operate smoothly.

(D) Normal position

(E) Stop position

----------

N=400r/min Q=0mm3/st L=2mm T=6~9N-m(0.6~0.9kgf-m) M=4.0kg

----------

S=Dia6.5+0.09mm R=35mm

----------

N=400r/min Q=0mm3/st L=2mm T=6~9N-m(0.6~0.9kgf-m) M=4.0kg

----------

S=Dia6.5+0.09mm R=35mm

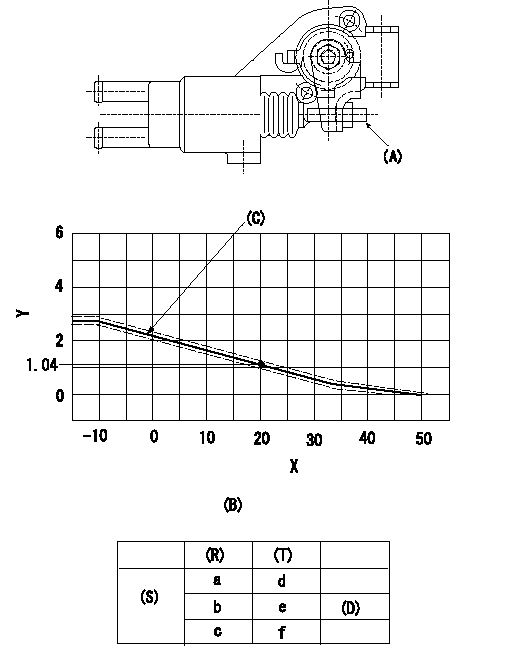

0000002001 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust screw A so that the timer advance angle determined in (B) can be obtained.

Y:Timer stroke TA (mm)

X:Temperature t (deg C)

(B) Timer stroke TA (mm):

TA = -0.059t + 2.22 ( -10 deg C <= t <= 20 deg C)

TA = -0.0433t + 1.906 ( 20 deg C <= t <= 35 deg C)

TA = -0.0239t + 1.227 ( 35 deg C <= t)

(C) Tolerance +-0.1(mm)

(S) Cold advance

(R) Cooling water temperature (deg C)

(T) Timer piston stroke (mm)

(D) Standard point

----------

----------

(C)=TA+-0.1mm a=56degC b=20degC c=-10degC d=0mm e=1.04+-0.4mm f=2.81+-0.6mm

----------

----------

(C)=TA+-0.1mm a=56degC b=20degC c=-10degC d=0mm e=1.04+-0.4mm f=2.81+-0.6mm

Information:

Start By:a. remove oil pump1. Check the identification marks on the connecting rods and caps as to their location in the engine. The caps must be installed in original positions in the engine.2. Turn the crankshaft until two of the pistons are at bottom center. 3. Remove connecting rod caps (1) from the connecting rods. Remove the lower half of the bearings from the caps.

Be careful not to damage the crankshaft journals. Do not turn the crankshaft while any of the connecting rod caps are removed.

4. Push the connecting rod away from the crankshaft, and remove the upper half of the bearings from the connecting rods.5. Make sure the surface of the connecting rod where the bearings make contact is clean and free of dirt.

Make sure the tabs on the bearings are in alignment with the notches in the connecting rods and caps.

6. Install the upper half of new bearings in the connecting rods.7. Pull the connecting rod down slowly on the crankshaft.

Make sure the surfaces where the bearings make contact in the caps are clean and free of dirt.

8. Install new bearings (2) in the caps. Make sure the tabs on the bearings are in alignment with the notches in the caps.The serviceman must be very careful to use Plastigage correctly. The following points must be remembered:... Make sure that the backs of the bearings and the bores are clean and dry.... Make sure that the bearing locking tabs are properly seated in their slots.... The crankshaft must be free of oil where the Plastigage touches it.... Put a piece of Plastigage on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.... Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.... Do not turn the crankshaft with the Plastigage installed. ... Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.... Remove the Plastigage before installing the cap.When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004 in) the readings may be low by 0.013 to 0.025 mm (.0005 to .0010 in). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider that the other.For complete details concerning measuring bearing clearances, see Engine Bearings & Crankshafts, SEBD0531.9. Put 2P-2506 Thread Lubricant on the threads of the bolts in the connecting rods.10. Check the bearing clearance with Plastigage (A) as follows:

When Plastigage is used to check

Be careful not to damage the crankshaft journals. Do not turn the crankshaft while any of the connecting rod caps are removed.

4. Push the connecting rod away from the crankshaft, and remove the upper half of the bearings from the connecting rods.5. Make sure the surface of the connecting rod where the bearings make contact is clean and free of dirt.

Make sure the tabs on the bearings are in alignment with the notches in the connecting rods and caps.

6. Install the upper half of new bearings in the connecting rods.7. Pull the connecting rod down slowly on the crankshaft.

Make sure the surfaces where the bearings make contact in the caps are clean and free of dirt.

8. Install new bearings (2) in the caps. Make sure the tabs on the bearings are in alignment with the notches in the caps.The serviceman must be very careful to use Plastigage correctly. The following points must be remembered:... Make sure that the backs of the bearings and the bores are clean and dry.... Make sure that the bearing locking tabs are properly seated in their slots.... The crankshaft must be free of oil where the Plastigage touches it.... Put a piece of Plastigage on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.... Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.... Do not turn the crankshaft with the Plastigage installed. ... Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.... Remove the Plastigage before installing the cap.When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004 in) the readings may be low by 0.013 to 0.025 mm (.0005 to .0010 in). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider that the other.For complete details concerning measuring bearing clearances, see Engine Bearings & Crankshafts, SEBD0531.9. Put 2P-2506 Thread Lubricant on the threads of the bolts in the connecting rods.10. Check the bearing clearance with Plastigage (A) as follows:

When Plastigage is used to check

Have questions with 104742-7540?

Group cross 104742-7540 ZEXEL

Yanmar

104742-7540

INJECTION-PUMP ASSEMBLY

4JH4-TE

4JH4-TE