Information injection-pump assembly

BOSCH

9 460 613 321

9460613321

ZEXEL

104742-7260

1047427260

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104742-7260 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104642-7260 |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Include in #2:

104742-7260

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 321

9460613321

ZEXEL

104742-7260

1047427260

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

68.4

67.9

68.9

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

39.4

33.4

45.4

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

38.9

32.9

44.9

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

45.3

40.8

49.8

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

64.4

59.9

68.9

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1600

1600

1600

Average injection quantity

mm3/st.

68.4

67.4

69.4

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1925

1925

1925

Average injection quantity

mm3/st.

65.4

60.9

69.9

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

5.2

2.2

8.2

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

3

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

5.2

0.7

9.7

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

338

338

338

Average injection quantity

mm3/st.

15

13

17

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

338

338

338

Average injection quantity

mm3/st.

15

12.5

17.5

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

65

105

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

85

65

105

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_03

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

65

105

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet ON at idling position and reversed operate

Magnet ON at idling position and reversed operate

Speed control lever angle_02

Pump speed

r/min

338

338

338

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet ON at idling position and reversed operate

Magnet ON at idling position and reversed operate

Speed control lever angle_03

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position and stop lever operate

Magnet OFF at idling position and stop lever operate

Speed control lever angle_04

Pump speed

r/min

338

338

338

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position and stop lever operate

Magnet OFF at idling position and stop lever operate

0000000901

Pump speed

r/min

1050

1050

1050

Overflow quantity

cm3/min

1280

1050

1510

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1050

1050

1050

Pressure

kPa

510

481

539

Pressure

kgf/cm2

5.2

4.9

5.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

950

950

950

Pressure

kPa

490

451

529

Pressure

kgf/cm2

5

4.6

5.4

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1050

1050

1050

Pressure

kPa

510

471

549

Pressure

kgf/cm2

5.2

4.8

5.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1925

1925

1925

Pressure

kPa

706

667

745

Pressure

kgf/cm2

7.2

6.8

7.6

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1050

1050

1050

Timer stroke

mm

0.8

0.6

1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1050

1050

1050

Timer stroke

mm

0.8

0.4

1.2

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1925

1925

1925

Timer stroke

mm

1.7

1.2

2.1

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

Reverse operation (At Normal: OFF, At Stop: ON) V 13 12 14

Reverse operation (At Normal: OFF, At Stop: ON) V 13 12 14

Timing setting

K dimension

mm

3.6

3.5

3.7

KF dimension

mm

5.54

5.44

5.64

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.2

0.18

0.22

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

38.5

33.5

43.5

Test data Ex:

0000001801 Temp. adjust full-load screw

Temporary full load screw adjustment

Set the full load screw protrusion at L mm at assembly.

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

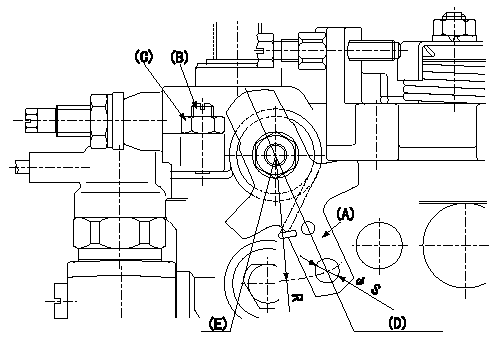

0000001901 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

1. Confirm that the starting injection quantity is within standards at the normal position.

If below the specified lower limit, move the stop lever serrations one tooth and reconfirm.

2. Pull the stop lever (A) to the fuel cut direction at the standard idling speed of N and adjust the screw (B) to the position Q.

Fix nut (C) to the torque T at the position where the clearance between the stop lever and the end of the screw is L mm (the screw is returned 2 turns).

The head of the screw must protrude above the face of the nut. If the head of the screw is below the face of the nut, adjust the clearance between the stop lever A and the end of the screw at Q to L mm or more.

3. If adjustment in item 2 is not possible, move the stop lever installation position 1 tooth.

4. The stop lever's operating force is max. M kg (at R = 35). The stop lever must operate smoothly.

(D) Normal position

(E) Stop position

----------

N=338r/min Q=0mm3/st T=6~9N-m(0.6~0.9kgf-m) L=2mm M=4.0kg

----------

S=Dia6.5+0.09mm R=35mm

----------

N=338r/min Q=0mm3/st T=6~9N-m(0.6~0.9kgf-m) L=2mm M=4.0kg

----------

S=Dia6.5+0.09mm R=35mm

Information:

Flangeless Liners

(1) Outside diameter of cylinder liner ... 103.28 to 103.30 mm (4.066 to 4.067 in)(2) Inside diameter of cylinder liner ... 98.48 to 98.50 mm (3.877 to 3.878 in) Maximum diameter wear (when boring or new liners are needed) ... 0.20 mm (0.008 in)Interference fit of liner in cylinder block ... 0.08 to 0.13 mm (0.003 to 0.005 in)Length of cylinder liner ... 228.73 to 228.98 mm (9.005 to 9.015 in)Maximum cylinder liner can be bored (made larger than original size) ... 0.76 mm (0.030 in) The 4.236 flangeless cylinder liners are the only ones that can be bored. All other liners must be replaced when worn beyond specifications.(3) Liner projection (height of liner above face of cylinder block) ... 0.71 to 0.94 mm (0.028 to 0.037 in)(4) Diameter of parent bore in cylinder block for liner ... 103.162 to 103.188 mm (4.0615 to 4.0625 in)Flanged Liners

New cylinder blocks have been introduced on the 4.236 engine. The 4.236 engine has a larger cylinder liner parent bore diameter and the outside diameter of the cylinder liner is also larger. The liners will no longer have a flame ring. Effective with this change only flanged liners will be available. The change became effective at engine serial number LDU106654N and up. See General Information in Systems Operation for the serial number location.(1) Outside diameter of cylinder liner.Earlier engines with thin wall liners: Production liner ... 103.238 to 103.264 mm (4.0645 to 4.0655 in)Service liner ... 103.188 to 103.213 mm (4.0625 to 4.0635 in)Current engines with thick wall liners: Production liner ... 104.254 to 104.280 mm (4.1045 to 4.1055 in)Service liner ... 104.204 to 104.229 mm (4.1025 to 4.1035 in)(2) Inside diameter of cylinder liner: Production liner ... 98.48 to 98.50 mm (3.877 to 3.878 in)Service liner ... 98.50 to 98.53 mm (3.878 to 3.879 in)Maximum diameter wear (when new liners are needed ... 0.20 mm (0.008 in)Transition fit of service liner in cylinder block ... 0.03 mm ( 0.001 in)Length of cylinder liner with flame ring ... 227.10 to 227.43 mm (8.941 to 8.954 in)Length of cylinder liner without flame ring ... 226.03 to 226.82 mm (8.899 to 8.930 in)(3) Liner (flange) projection [do not measure from flame ring (if equipped)] ... 0.10 mm (0.004 in) above to 0.10 mm (0.004 in) below face of cylinder block. Flange thickness of cylinder liner ... 3.81 to 3.86 mm (0.150 to 0.152 in)(4) Diameter of parent bore in cylinder block in liner: Earlier engines with thin wall liners ... 103.188 to 103.213 mm (4.0625 to 4.0635 in)Current engines with thick wall liners ... 104.204 to 104.229 mm (4.1025 to 4.1035 in)Depth of recess for cylinder liner flange ... 3.81 to 3.91 mm (0.150 to 0.154 in)All Engine Blocks

(5) Diameter of bore in cylinder block for camshaft No. 1 front bearing [has only front bearing (6)] ...

(1) Outside diameter of cylinder liner ... 103.28 to 103.30 mm (4.066 to 4.067 in)(2) Inside diameter of cylinder liner ... 98.48 to 98.50 mm (3.877 to 3.878 in) Maximum diameter wear (when boring or new liners are needed) ... 0.20 mm (0.008 in)Interference fit of liner in cylinder block ... 0.08 to 0.13 mm (0.003 to 0.005 in)Length of cylinder liner ... 228.73 to 228.98 mm (9.005 to 9.015 in)Maximum cylinder liner can be bored (made larger than original size) ... 0.76 mm (0.030 in) The 4.236 flangeless cylinder liners are the only ones that can be bored. All other liners must be replaced when worn beyond specifications.(3) Liner projection (height of liner above face of cylinder block) ... 0.71 to 0.94 mm (0.028 to 0.037 in)(4) Diameter of parent bore in cylinder block for liner ... 103.162 to 103.188 mm (4.0615 to 4.0625 in)Flanged Liners

New cylinder blocks have been introduced on the 4.236 engine. The 4.236 engine has a larger cylinder liner parent bore diameter and the outside diameter of the cylinder liner is also larger. The liners will no longer have a flame ring. Effective with this change only flanged liners will be available. The change became effective at engine serial number LDU106654N and up. See General Information in Systems Operation for the serial number location.(1) Outside diameter of cylinder liner.Earlier engines with thin wall liners: Production liner ... 103.238 to 103.264 mm (4.0645 to 4.0655 in)Service liner ... 103.188 to 103.213 mm (4.0625 to 4.0635 in)Current engines with thick wall liners: Production liner ... 104.254 to 104.280 mm (4.1045 to 4.1055 in)Service liner ... 104.204 to 104.229 mm (4.1025 to 4.1035 in)(2) Inside diameter of cylinder liner: Production liner ... 98.48 to 98.50 mm (3.877 to 3.878 in)Service liner ... 98.50 to 98.53 mm (3.878 to 3.879 in)Maximum diameter wear (when new liners are needed ... 0.20 mm (0.008 in)Transition fit of service liner in cylinder block ... 0.03 mm ( 0.001 in)Length of cylinder liner with flame ring ... 227.10 to 227.43 mm (8.941 to 8.954 in)Length of cylinder liner without flame ring ... 226.03 to 226.82 mm (8.899 to 8.930 in)(3) Liner (flange) projection [do not measure from flame ring (if equipped)] ... 0.10 mm (0.004 in) above to 0.10 mm (0.004 in) below face of cylinder block. Flange thickness of cylinder liner ... 3.81 to 3.86 mm (0.150 to 0.152 in)(4) Diameter of parent bore in cylinder block in liner: Earlier engines with thin wall liners ... 103.188 to 103.213 mm (4.0625 to 4.0635 in)Current engines with thick wall liners ... 104.204 to 104.229 mm (4.1025 to 4.1035 in)Depth of recess for cylinder liner flange ... 3.81 to 3.91 mm (0.150 to 0.154 in)All Engine Blocks

(5) Diameter of bore in cylinder block for camshaft No. 1 front bearing [has only front bearing (6)] ...