Information injection-pump assembly

BOSCH

9 460 614 973

9460614973

ZEXEL

104742-7133

1047427133

YANMAR

12969851900

12969851900

Rating:

Cross reference number

BOSCH

9 460 614 973

9460614973

ZEXEL

104742-7133

1047427133

YANMAR

12969851900

12969851900

Zexel num

Bosch num

Firm num

Name

104742-7133

9 460 614 973

12969851900 YANMAR

INJECTION-PUMP ASSEMBLY

4JH3-DTZ K

4JH3-DTZ K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

950

950

950

Boost pressure

kPa

24

22.7

25.3

Boost pressure

mmHg

180

170

190

Average injection quantity

mm3/st.

61.7

61.2

62.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

950

950

950

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

73.2

72.7

73.7

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

30

30

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

39.4

39.4

39.4

Oil temperature

degC

48

46

50

Injection timing adjustment_05

Pump speed

r/min

950

950

950

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

44.6

44.6

44.6

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

950

950

950

Boost pressure

kPa

24

22.7

25.3

Boost pressure

mmHg

180

170

190

Average injection quantity

mm3/st.

61.7

60.7

62.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_07

Pump speed

r/min

950

950

950

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

73.2

72.2

74.2

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_08

Pump speed

r/min

1330

1330

1330

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

76.3

71.3

81.3

Oil temperature

degC

50

48

52

Injection timing adjustment_09

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

86

81

91

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

11.2

6.7

15.7

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2150

2150

2150

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Average injection quantity

mm3/st.

11.2

6.2

16.2

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

338

338

338

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

20.2

18.2

22.2

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

338

338

338

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

20.2

17.7

22.7

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

87.3

67.3

107.3

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

87.3

67.3

107.3

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

338

338

338

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

338

338

338

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet ON at idling position and stop lever operate

Magnet ON at idling position and stop lever operate

0000000901

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Overflow quantity

cm3/min

395

265

525

Oil temperature

degC

52

50

54

Stop lever angle

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

510

481

539

Pressure

kgf/cm2

5.2

4.9

5.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

950

950

950

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

490

451

529

Pressure

kgf/cm2

5

4.6

5.4

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

510

471

549

Pressure

kgf/cm2

5.2

4.8

5.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Pressure

kPa

677

638

716

Pressure

kgf/cm2

6.9

6.5

7.3

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

0.8

0.6

1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

0.8

0.4

1.2

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

66.7

65.4

68

Boost pressure

mmHg

500

490

510

Timer stroke

mm

1.7

1.2

2.1

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.6

3.5

3.7

KF dimension

mm

6.85

6.75

6.95

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

4.5

4.4

4.6

Pre-stroke

mm

0.2

0.18

0.22

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

41

36

46

Test data Ex:

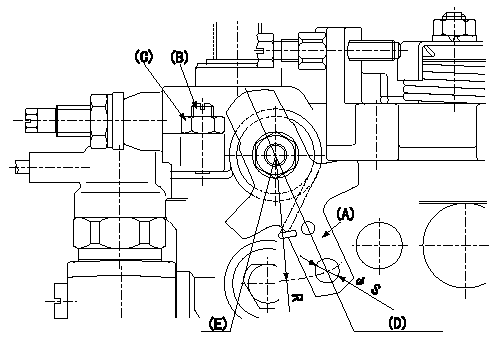

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

1. Confirm that the starting injection quantity is within standards at the normal position.

If below the specified lower limit, move the stop lever serrations one tooth and reconfirm.

2. Pull the stop lever (A) to the fuel cut direction at the standard idling speed of N and adjust the screw (B) to the position Q.

Fix nut (C) to the torque T at the position where the clearance between the stop lever and the end of the screw is L mm (the screw is returned 2 turns).

The head of the screw must protrude above the face of the nut. If the head of the screw is below the face of the nut, adjust the clearance between the stop lever A and the end of the screw at Q to L mm or more.

3. If adjustment in item 2 is not possible, move the stop lever installation position 1 tooth.

4. The stop lever's operating force is max. M kg (at R = 35). The stop lever must operate smoothly.

(D) Normal position

(E) Stop position

----------

N=338r/min Q=0mm3/st T=6~9N-m(0.6~0.9kgf-m) L=2mm M=4.0kg

----------

S=Dia6.5+0.09-0mm R=35mm

----------

N=338r/min Q=0mm3/st T=6~9N-m(0.6~0.9kgf-m) L=2mm M=4.0kg

----------

S=Dia6.5+0.09-0mm R=35mm

Information:

Start By:a. remove timing gear coverb. remove push rods and valve lifters 1. Remove air compressor outlet hose (1). (Not applicable).2. Remove air compressor air inlet tube (3). (Not applicable).3. Remove air compressor coolant outlet tube (4). (Not applicable)4. Remove turbocharger oil return tube (2). 5. Use Tooling (A) to remove studs (5).6. Turn the flywheel with Tool (B), and remove each bolt (6) as it becomes accessible.7. Turn the flywheel with Tool (B) until the "V" marks on the front timing gears are in alignment.8. Install Tooling (C) through the holes for studs (5) into camshaft rear gear (7).

Tooling (C) must be used to prevent the loss of rear balance weight timing and to keep the camshaft rear gear in place when the camshaft is removed.

9. Tighten Tooling (C) evenly to remove the camshaft rear gear from the camshaft. 10. Remove thrust plate (8).

Be careful not to damage the camshaft bearings. Do not pry the camshaft out of the cylinder block. If resistance to camshaft removal occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores.

11. Carefully remove the camshaft and gear (9) from the cylinder block.12. If removal of the camshaft gear is necessary, place the camshaft and gear in a hydraulic press. Place Tool (D) over the camshaft, and press against it to remove the camshaft from the gear.

Be careful not to scratch or mar the finished surfaces of the camshaft.

13. Remove the key from the camshaft.14. If dowel removal is necessary, use Tool (E) to remove the dowel.Install Camshaft

1. Install the key in the camshaft. Be sure the key is seated in the camshaft.2. Install the pin in the rear of the camshaft. Install the pin to a height of 8.51 to 9.01 mm (.335 to .355 in).3. Heat the camshaft drive gear to a maximum temperature of 204° C (400° F), align the groove in the drive gear with the key in the camshaft, and install the camshaft drive gear with the timing marks away from the camshaft.4. Put clean engine oil on the camshaft bearing journals and lobes.5. Carefully install the camshaft into the cylinder block. Do not force the camshaft into position. If resistance to camshaft installation occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores. 6. Align the "V" marks on camshaft drive gear (2) and idler gear (3).7. Install thrust plate (1) to hold the camshaft and camshaft drive gear (2) in the cylinder block. 8. Loosen the bolts Tool (B) that hold camshaft rear gear (5) so camshaft rear gear (5) will engage the dowel on the rear of the camshaft.9. After the dowel is engaged, remove Tool (B), and install bolts (4).10. Use Tool (A) to turn the flywheel, and install each of four bolts (4). Tighten bolts (4) to a torque of 23 to 31 N m (17 to 23 lb ft).11. Put 5P-3413 Pipe Sealant with "Teflon" on the

Tooling (C) must be used to prevent the loss of rear balance weight timing and to keep the camshaft rear gear in place when the camshaft is removed.

9. Tighten Tooling (C) evenly to remove the camshaft rear gear from the camshaft. 10. Remove thrust plate (8).

Be careful not to damage the camshaft bearings. Do not pry the camshaft out of the cylinder block. If resistance to camshaft removal occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores.

11. Carefully remove the camshaft and gear (9) from the cylinder block.12. If removal of the camshaft gear is necessary, place the camshaft and gear in a hydraulic press. Place Tool (D) over the camshaft, and press against it to remove the camshaft from the gear.

Be careful not to scratch or mar the finished surfaces of the camshaft.

13. Remove the key from the camshaft.14. If dowel removal is necessary, use Tool (E) to remove the dowel.Install Camshaft

1. Install the key in the camshaft. Be sure the key is seated in the camshaft.2. Install the pin in the rear of the camshaft. Install the pin to a height of 8.51 to 9.01 mm (.335 to .355 in).3. Heat the camshaft drive gear to a maximum temperature of 204° C (400° F), align the groove in the drive gear with the key in the camshaft, and install the camshaft drive gear with the timing marks away from the camshaft.4. Put clean engine oil on the camshaft bearing journals and lobes.5. Carefully install the camshaft into the cylinder block. Do not force the camshaft into position. If resistance to camshaft installation occurs, turn the camshaft so the lobes will align the bearing journals with the camshaft bearing bores. 6. Align the "V" marks on camshaft drive gear (2) and idler gear (3).7. Install thrust plate (1) to hold the camshaft and camshaft drive gear (2) in the cylinder block. 8. Loosen the bolts Tool (B) that hold camshaft rear gear (5) so camshaft rear gear (5) will engage the dowel on the rear of the camshaft.9. After the dowel is engaged, remove Tool (B), and install bolts (4).10. Use Tool (A) to turn the flywheel, and install each of four bolts (4). Tighten bolts (4) to a torque of 23 to 31 N m (17 to 23 lb ft).11. Put 5P-3413 Pipe Sealant with "Teflon" on the

Have questions with 104742-7133?

Group cross 104742-7133 ZEXEL

Yanmar

Yanmar

Yanmar

Yanmar

104742-7133

9 460 614 973

12969851900

INJECTION-PUMP ASSEMBLY

4JH3-DTZ

4JH3-DTZ