Information injection-pump assembly

BOSCH

9 460 614 493

9460614493

ZEXEL

104742-7061

1047427061

KOMATSU

6202721330

6202721330

Rating:

Cross reference number

BOSCH

9 460 614 493

9460614493

ZEXEL

104742-7061

1047427061

KOMATSU

6202721330

6202721330

Zexel num

Bosch num

Firm num

Name

104742-7061

9 460 614 493

6202721330 KOMATSU

INJECTION-PUMP ASSEMBLY

4D95S-W K

4D95S-W K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Timer measuring device installation position

High pressure side HIGH PRESSURE SIDE

High pressure side HIGH PRESSURE SIDE

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.3

46.8

47.8

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

43.9

41.4

46.4

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

47.3

46.3

48.3

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1225

1225

1225

Average injection quantity

mm3/st.

48.8

46.3

51.3

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

26.7

23.7

29.7

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

26.7

23.2

30.2

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

11.2

9.2

13.2

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

11.2

8.7

13.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

58

53

63

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

58

53

63

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

460

330

590

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

500

480

520

Pressure

kgf/cm2

5.1

4.9

5.3

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

500

471

529

Pressure

kgf/cm2

5.1

4.8

5.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1225

1225

1225

Pressure

kPa

579

540

618

Pressure

kgf/cm2

5.9

5.5

6.3

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1225

1225

1225

Timer stroke

mm

6.7

6.3

7.2

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

0000001401

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

31

30.5

31.5

Timer stroke TA

mm

4

3.8

4.2

Timer stroke variation dT

mm

0.8

0.8

0.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

31

30

32

Timer stroke TA

mm

4

3.7

4.3

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

22

20.5

23.5

Timer stroke TA

mm

3.2

2.7

3.7

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5

4.9

5.1

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

16

12

20

Control lever angle beta

deg.

38

33

43

Test data Ex:

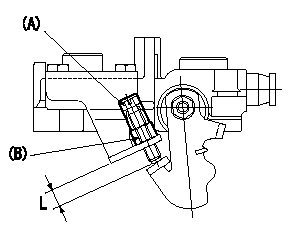

0000001801 STARTING I/Q ADJUSTMENT

Starting Q decrease lever adjustment

At injection quantity adjustment, adjust using the bolt so that the starting injection quantity is as specified. Fix using the nut. (Tightening torque T)

Bolt (A) protrusion: L

(B) = nut

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

----------

L=7.4~11.1mm

Information:

Start By:a. remove flywheelb. remove crankshaft rear seal and wear sleeve **Remove the crankshaft rear seal and wear sleeve only if the engine is equipped with the later design seal. The later design seal can be identified by the rotation marks on the seal.

Some flywheel housings will have more bolts holding the flywheel housing to the cylinder block.

1. If the engine is equipped with an electric starting motor, remove the electric starting motor from the flywheel housing.2. Remove the bolts that hold the oil pan plate to the flywheel housing. Loosen the bolts that hold the oil pan plate to the cylinder block.3. Install spacers between the oil pan plate and the cylinder block to hold the oil pan plate away from the flywheel housing.

3306 Engine Shown4. On 3306 Engines, remove turbocharger oil drain pipe (1).5. Install Tool (A) on the flywheel housing as shown, and fasten a hoist to it.6. Remove all bolts (2) and the flywheel housing from the engine. The weight of the flywheel housing is 37 kg (82 lb).Install Flywheel Housing

3306 Engine Shown1. Install Tool (A) on the flywheel housing. Fasten a hoist to the flywheel housing. 2. Put the gasket and flywheel housing in position on the engine. Install bolts (2) that hold it. Tighten the bolts to a torque of 100 14 N m (74 10 lb ft) as shown.3. Remove Tool (A) from the flywheel housing.4. On 3306 Engines, install turbocharger oil drain line (1).5. Cut the bottom of the flywheel housing gasket off even with the cylinder block and flywheel housing. Put 3S6252 RTV Silicone Adhesive/Sealant on the bottom of the gasket where it makes contact with the oil pan plate gasket.6. Remove the spacers from between the oil pan plate and the cylinder block. Install the bolts that hold the oil pan plate to the flywheel housing. Tighten the bolts that hold the oil pan plate to the cylinder block.7. If the engine is equipped with an electric starting motor, install it on the flywheel housing.End By:a. install crankshaft rear seal and wear sleeveb. install flywheel

Some flywheel housings will have more bolts holding the flywheel housing to the cylinder block.

1. If the engine is equipped with an electric starting motor, remove the electric starting motor from the flywheel housing.2. Remove the bolts that hold the oil pan plate to the flywheel housing. Loosen the bolts that hold the oil pan plate to the cylinder block.3. Install spacers between the oil pan plate and the cylinder block to hold the oil pan plate away from the flywheel housing.

3306 Engine Shown4. On 3306 Engines, remove turbocharger oil drain pipe (1).5. Install Tool (A) on the flywheel housing as shown, and fasten a hoist to it.6. Remove all bolts (2) and the flywheel housing from the engine. The weight of the flywheel housing is 37 kg (82 lb).Install Flywheel Housing

3306 Engine Shown1. Install Tool (A) on the flywheel housing. Fasten a hoist to the flywheel housing. 2. Put the gasket and flywheel housing in position on the engine. Install bolts (2) that hold it. Tighten the bolts to a torque of 100 14 N m (74 10 lb ft) as shown.3. Remove Tool (A) from the flywheel housing.4. On 3306 Engines, install turbocharger oil drain line (1).5. Cut the bottom of the flywheel housing gasket off even with the cylinder block and flywheel housing. Put 3S6252 RTV Silicone Adhesive/Sealant on the bottom of the gasket where it makes contact with the oil pan plate gasket.6. Remove the spacers from between the oil pan plate and the cylinder block. Install the bolts that hold the oil pan plate to the flywheel housing. Tighten the bolts that hold the oil pan plate to the cylinder block.7. If the engine is equipped with an electric starting motor, install it on the flywheel housing.End By:a. install crankshaft rear seal and wear sleeveb. install flywheel

Have questions with 104742-7061?

Group cross 104742-7061 ZEXEL

Yanmar

Komatsu

Komatsu

Komatsu

104742-7061

9 460 614 493

6202721330

INJECTION-PUMP ASSEMBLY

4D95S-W

4D95S-W