Information injection-pump assembly

ZEXEL

104742-4030

1047424030

NISSAN-DIESEL

1670018T01

1670018t01

Rating:

Cross reference number

ZEXEL

104742-4030

1047424030

NISSAN-DIESEL

1670018T01

1670018t01

Zexel num

Bosch num

Firm num

Name

104742-4030

1670018T01 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

FD35 *

FD35 *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

61.9

61.4

62.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

67.7

67.7

67.7

Oil temperature

degC

47

45

49

Injection timing adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

56

53.5

58.5

Oil temperature

degC

47

45

49

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

61.9

60.9

62.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

66

63

69

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

25.1

22.1

28.1

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

2200

2200

2200

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

49

55

Injection quantity adjustment_03

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

25.1

21.6

28.6

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

19.4

17.4

21.4

Difference in delivery

mm3/st.

3.9

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

17.9

15.4

20.4

Difference in delivery

mm3/st.

3.7

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

85

125

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

85

85

125

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

300

170

430

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1400

1400

1400

Pressure

kPa

618

598

638

Pressure

kgf/cm2

6.3

6.1

6.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

471

432

510

Pressure

kgf/cm2

4.8

4.4

5.2

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1400

1400

1400

Pressure

kPa

618

579

657

Pressure

kgf/cm2

6.3

5.9

6.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1750

1750

1750

Pressure

kPa

745

706

784

Pressure

kgf/cm2

7.6

7.2

8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

2.2

2

2.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

2.2

1.8

2.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1600

1600

1600

Timer stroke

mm

3.9

3.3

4.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1750

1750

1750

Timer stroke

mm

4.9

4.4

5.3

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.7

0.6

0.8

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

33.5

28.5

38.5

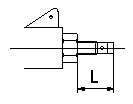

Test data Ex:

0000001801 TEMP. ADJUST FULL-LOAD SCREW

Temporary full load screw adjustment

At reassembly set the distance that the full load screw protrudes at L.

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

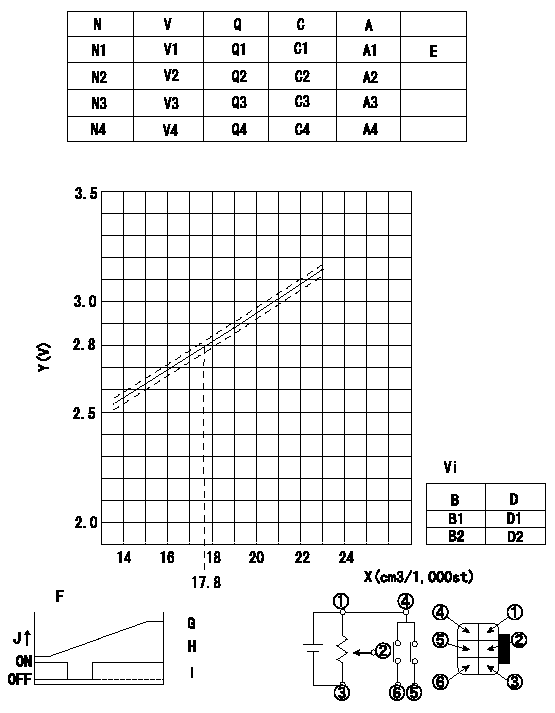

0000001901 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Measure the injection quantity with the control lever a from the idle position (equal to shim thickness L1) at pump speed N5. Install the potentiometer so that injection quantity and output voltage correspond as shown in the graph.

Confirm at least V5 at full lever position.

Reference value: conversion expression

17.4 < X < 23.5 V+-0.03 = 0.063X+0.94

29>X>23.5 V+-0.03=0.04X+1.48

17.4 > X V = 2.07

29<X V=2.64

A = shim thickness

B = changeover point

C = control lever angle

D = lever position (from idle)

E = adjusting point

Vi = applied voltage

V = potentiometer voltage

X = injection quantity Q

Y = voltage (V)

B1 = idle switch ON to OFF

B2 = full switch OFF to ON

F = potentiometer wiring diagram

G = output between connections (2) and (3)

H = switch OFF to ON at connections 4 and 6.

I = switch ON to OFF at connecting harnesses 4 and 5

J = output

K = idle

N = pump speed

Q = injection quantity

----------

N5=500r/min a=8.8deg L1=5.7mm V5=5V

----------

N1=500r/min N2=500r/min N3=500r/min N4=0r/min V1=(2.07)V V2=2.37+-0.03V V3=(2.74)V V4=0.9+-0.4V Q1=Measure cm3/1,000st Q2=22.2+-4cm3/1,000st Q3=Measure cm3/1,000st Q4=- cm3/1,000st C1=(7)deg C2=(8.8)deg C3=(11)deg C4=0deg A1=(4.5+-0.05)mm A2=(5.7+-0.05)mm A3=(7.1+-0.05)mm A4=0mm Vi=10 V D1=(4.6+-2.6)deg D2=(23.6+-2.6)deg

----------

N5=500r/min a=8.8deg L1=5.7mm V5=5V

----------

N1=500r/min N2=500r/min N3=500r/min N4=0r/min V1=(2.07)V V2=2.37+-0.03V V3=(2.74)V V4=0.9+-0.4V Q1=Measure cm3/1,000st Q2=22.2+-4cm3/1,000st Q3=Measure cm3/1,000st Q4=- cm3/1,000st C1=(7)deg C2=(8.8)deg C3=(11)deg C4=0deg A1=(4.5+-0.05)mm A2=(5.7+-0.05)mm A3=(7.1+-0.05)mm A4=0mm Vi=10 V D1=(4.6+-2.6)deg D2=(23.6+-2.6)deg

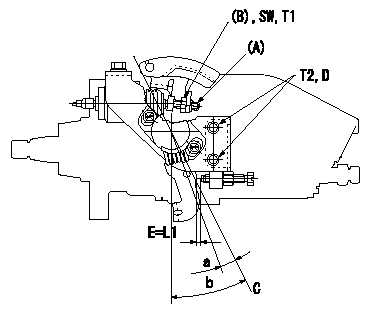

0000002001 ACCELERATOR SWITCH ADJ

Accelerator switch adjustment

ON - OFF changeover point: from idle to a (shim thickness E = L)

Idle-c: ON

d ~ full: OFF

E = shim thickness

Insert a block gauge thickness L1 (corresponding to lever position a) between the idle set screw and the control lever and set the switch using the screw (A) so that it moves from ON to OFF. Then tighten the nut (B).

C = idle lever position

D = 2 of 2 locations

----------

a=3.5deg c=3.5deg d=3.5deg L=2.3+-0.1mm L1=2.3mm

----------

a=3.5deg b=25+-4deg SW=SW10 T1=5~7N-m(0.5~0.7kgf-m) T2=7~10N-m(0.7~1kgf-m) L1=2.3mm

----------

a=3.5deg c=3.5deg d=3.5deg L=2.3+-0.1mm L1=2.3mm

----------

a=3.5deg b=25+-4deg SW=SW10 T1=5~7N-m(0.5~0.7kgf-m) T2=7~10N-m(0.7~1kgf-m) L1=2.3mm

Information:

Typical Example1. Remove bolts (1) from the alternator bracket.2. Remove the bolts that hold plate (3) and remove the plate.3. Disconnect water line (2) from the air compressor. Turn the water line tee toward the lifting bracket in order to provide clearance to remove the head bolt. 4. Remove bolts (4) and (5) that hold the cylinder head assembly to the cylinder block.5. Fasten a hoist and remove the cylinder head assembly. The weight is approximately 135 kg (300 lb).

Do not put the cylinder head assembly down on a flat surface. This can cause damage to the fuel injection valves.

6. Remove the gasket and seals from the spacer plate.Install Cylinder Head Assembly

Be sure a new gasket has been installed between the spacer plate and the cylinder block. See topic, "Remove & Install Spacer Plate". 1. Thoroughly clean the spacer plate and the bottom surface of the cylinder head assembly. Install a new head gasket, new seals (1) and two O-ring seals (2). 2. Fasten a hoist and put the cylinder head assembly (3) in position on the cylinder block.3. Tighten the bolts in sequence shown in Illustration D11970.

(1) Large bolts (3/4 inch). Put 6V4876 Molycoat Paste Lubricant on bolt threads and between washers and underside of bolt heads.(2) Small bolts (3/8 inch). See Step 4h.4. Install the cylinder head bolts and washers. Tighten the bolts in sequence shown.a. Tighten bolts 1 through 14 in number sequence to 270 25 N m (200 20 lb ft).b. Tighten bolts 1 through 14 in number sequence to 470 20 N m (345 15 lb ft).c. Tighten bolts 1 through 14 in number sequence again to 470 20 N m (345 15 lb ft).d. Install the rocker arm shafts for the engine valves and the remaining (3/4 in) bolts and/or compression brake studs.e. Tighten bolts 15 through 26 in number sequence to 270 25 N m (200 20 lb ft).f. Tighten bolts 15 through 26 in number sequence to 450 20 N m (330 15 lb ft).g. Tighten bolts 15 through 26 in number sequence again to 450 20 N m (330 15 lb ft).h. Tighten the thirteen small bolts (2) to 45 7 N m (33 5 lb ft).5. Make an adjustment to the valves to have a clearance of 0.38 mm (.015 in) for intake and 0.76 mm (.030 in) for exhaust. Tighten the locknuts for the valve adjustment screws to a torque of 28 4 N m (21 3 lb ft).6. Install the valve cover bases and the inner fuel lines. See topic, "Install Rocker Shaft Assemblies & Push Rods".7. Install the valve covers. See topic, "Install Valve Covers".

Typical Example8. Install plate (4).9. Connect the water line to the air compressor.10. Install bolts (5) for the alternator bracket.End By:a. install exhaust manifoldb. install fuel injection linesc. install aftercooler housingd. install water temperature regulatore. install rocker shaft assemblies and push rods

Have questions with 104742-4030?

Group cross 104742-4030 ZEXEL

Nissan-Diesel

104742-4030

1670018T01

INJECTION-PUMP ASSEMBLY

FD35

FD35