Information injection-pump assembly

ZEXEL

104742-1191

1047421191

ISUZU

8943427071

8943427071

Rating:

Cross reference number

ZEXEL

104742-1191

1047421191

ISUZU

8943427071

8943427071

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

65.1

64.6

65.6

Difference in delivery

mm3/st.

4

Basic

*

Injection timing adjustment_02

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

16.7

13.2

20.2

Injection timing adjustment_03

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

65.3

59.8

70.8

Injection timing adjustment_04

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

63

59

67

Injection timing adjustment_05

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

65.1

64.1

66.1

Injection timing adjustment_06

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

55.2

51.2

59.2

Injection timing adjustment_07

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

65.3

60.3

70.3

Injection quantity adjustment

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

16.6

13.6

19.6

Difference in delivery

mm3/st.

7

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

8

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.4

7.4

11.4

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

3

Governor adjustment_03

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.4

7.4

11.4

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1600

1600

1600

Overflow quantity with S/T OFF

cm3/min

621

492

750

Stop lever angle

Pump speed

r/min

1600

1600

1600

Pressure

kPa

588.5

569

608

Pressure

kgf/cm2

6

5.8

6.2

Basic

*

Stop lever angle_02

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

588.5

569

608

Pressure with S/T OFF

kgf/cm2

6

5.8

6.2

Stop lever angle_03

Pump speed

r/min

1750

1750

1750

Pressure with S/T OFF

kPa

637.5

608

667

Pressure with S/T OFF

kgf/cm2

6.5

6.2

6.8

0000001101

Pump speed

r/min

1600

1600

1600

Timer stroke

mm

3

2.8

3.2

Basic

*

_02

Pump speed

r/min

850

850

850

Timer stroke with S/T ON

mm

0.5

0.5

_03

Pump speed

r/min

1450

1450

1450

Timer stroke with S/T OFF

mm

0.5

_04

Pump speed

r/min

1500

1500

1500

Timer stroke with S/T OFF

mm

0.9

0.3

1.5

_05

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

3

2.7

3.3

_06

Pump speed

r/min

1750

1750

1750

Timer stroke with S/T OFF

mm

5.7

5.3

6.1

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.9

0.8

1

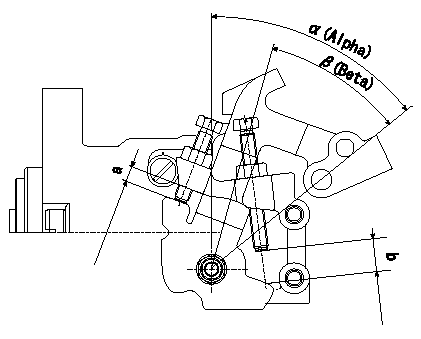

Control lever angle alpha

deg.

50

46

54

Control lever angle beta

deg.

37

32

42

Test data Ex:

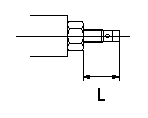

0000001801 Temp. adjust full-load screw

Temporary full load screw adjustment

Set the full load screw protrusion at L mm at assembly.

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

----------

L=14+-0.5mm

0000001901 CONTROL LEVER ANGLE

Lever angle alpha, beta

Dimensions a, b

----------

Alpha=50+-4deg Beta=37+-5deg a=(4.8~7.6)mm b=(11.8~16.4)mm

----------

Alpha=50+-4deg Beta=37+-5deg a=(4.8~7.6)mm b=(11.8~16.4)mm

----------

Alpha=50+-4deg Beta=37+-5deg a=(4.8~7.6)mm b=(11.8~16.4)mm

----------

Alpha=50+-4deg Beta=37+-5deg a=(4.8~7.6)mm b=(11.8~16.4)mm

Information:

Test Points (Voltages And Waveforms)

dc Voltages Conditions: 1. dc input voltage applied to POWER connector as shown.2. CALIBRATION CHECK/OPERATE switch in the OPERATE position.3. Neither transducer connected to indicator.4. TPI is reference for all voltages.Equipment Required: 6V3030 Digital Multimeterdc Input Voltages Waveforms Conditions: 1. dc power input voltage of 25 1 Volts.2. CALIBRATION CHECK/OPERATE switch in the CHECK position (can be held in CHECK position with tape).3. Neither transducer connected to indicator.4. TPI is reference for all waveforms.Equipment Required: dc oscilloscope (dual channel preferred). Waveform Time Relationships

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 2.66 ms WHICH IS BASED ON A 12.000 kHz OSCILLATOR FREQ. (1C202). SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Waveform Time Relationships (enlarged scale)

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 83.3 ?s AND 2.66 ms WHICH ARE EXACT BASED ON A 12.000 kHZ OSCILLATOR. (1C202) SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Disassembly Procedure

1 Remove six screws (1) from front panel (2), and remove panel (2) from case (3). Remove four screws (4) from the PC board, and also remove the locknuts from the two front panel switches (5) and (6). Carefully lift front panel (2) from PC (printed circuit) board (7).Calibration Procedure

To make sure the 6V3100 Timing Indicator Group (1) has good accuracy, check its calibration at a minimum of every six months. Also, the timing indicator will need calibration if: A. It does not show 2000 30 R/MIN at (A) and 32.0 .2 DEG at (B), when the CALIBRATION CHECK-OPERATE Switch (C) is in the CALIBRATION CHECK position. With no input signal at (D) or (E), the reading at R/MIN location (A) must show three zeros (000). If four zeros (0000) show, it is an indication of a possible need for calibration of the unit. This error only is not reason enough to do a complete calibration procedure. It is also not necessary to do a complete calibration procedure if the reading at the DEG location (B) has a decimal point as shown, (00.0) in addition to the three zeros.B. Reading is different than (000) at either location (A) or (B).All calibrations can be done with the use of a small screwdriver, a frequency counter and

dc Voltages Conditions: 1. dc input voltage applied to POWER connector as shown.2. CALIBRATION CHECK/OPERATE switch in the OPERATE position.3. Neither transducer connected to indicator.4. TPI is reference for all voltages.Equipment Required: 6V3030 Digital Multimeterdc Input Voltages Waveforms Conditions: 1. dc power input voltage of 25 1 Volts.2. CALIBRATION CHECK/OPERATE switch in the CHECK position (can be held in CHECK position with tape).3. Neither transducer connected to indicator.4. TPI is reference for all waveforms.Equipment Required: dc oscilloscope (dual channel preferred). Waveform Time Relationships

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 2.66 ms WHICH IS BASED ON A 12.000 kHz OSCILLATOR FREQ. (1C202). SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Waveform Time Relationships (enlarged scale)

VOLTAGES MAY VARY 10%, PULSE DURATIONS BY 20% EXCEPT 83.3 ?s AND 2.66 ms WHICH ARE EXACT BASED ON A 12.000 kHZ OSCILLATOR. (1C202) SIGNAL SOURCE IS INTERNAL CALIBRATOR. ALL TEST POINTS REFERENCED TO TP1.Disassembly Procedure

1 Remove six screws (1) from front panel (2), and remove panel (2) from case (3). Remove four screws (4) from the PC board, and also remove the locknuts from the two front panel switches (5) and (6). Carefully lift front panel (2) from PC (printed circuit) board (7).Calibration Procedure

To make sure the 6V3100 Timing Indicator Group (1) has good accuracy, check its calibration at a minimum of every six months. Also, the timing indicator will need calibration if: A. It does not show 2000 30 R/MIN at (A) and 32.0 .2 DEG at (B), when the CALIBRATION CHECK-OPERATE Switch (C) is in the CALIBRATION CHECK position. With no input signal at (D) or (E), the reading at R/MIN location (A) must show three zeros (000). If four zeros (0000) show, it is an indication of a possible need for calibration of the unit. This error only is not reason enough to do a complete calibration procedure. It is also not necessary to do a complete calibration procedure if the reading at the DEG location (B) has a decimal point as shown, (00.0) in addition to the three zeros.B. Reading is different than (000) at either location (A) or (B).All calibrations can be done with the use of a small screwdriver, a frequency counter and