Information injection-pump assembly

ZEXEL

104742-1031

1047421031

ISUZU

8944046181

8944046181

Rating:

Cross reference number

ZEXEL

104742-1031

1047421031

ISUZU

8944046181

8944046181

Zexel num

Bosch num

Firm num

Name

104742-1031

8944046181 ISUZU

INJECTION-PUMP ASSEMBLY

4BE1F *

4BE1F *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

65.4

64.9

65.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

65.4

60.9

69.9

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

56.8

53.3

60.3

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

65.4

64.4

66.4

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

65.5

61.5

69.5

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

66

60.5

71.5

Difference in delivery

mm3/st.

6

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

16.6

13.6

19.6

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

8

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

16.6

13.6

19.6

Difference in delivery

mm3/st.

7

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.5

6.5

10.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.5

6.5

10.5

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

80

120

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

80

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Overflow quantity

cm3/min

620

490

750

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

588

568

608

Pressure with S/T OFF

kgf/cm2

6

5.8

6.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

588

568

608

Pressure with S/T OFF

kgf/cm2

6

5.8

6.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1750

1750

1750

Pressure with S/T OFF

kPa

637

608

666

Pressure with S/T OFF

kgf/cm2

6.5

6.2

6.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

750

650

850

Timer stroke with S/T ON

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1450

1450

1450

Timer stroke with S/T OFF

mm

0.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1500

1500

1500

Timer stroke with S/T OFF

mm

0.9

0.5

1.2

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

1750

1750

1750

Timer stroke with S/T OFF

mm

5.7

5.4

6.1

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

50

46

54

Control lever angle beta

deg.

37

32

42

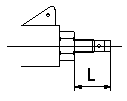

Test data Ex:

0000001801 Temp. adjust full-load screw

Temporary full load screw adjustment

Set the full load screw protrusion at L mm at assembly.

----------

L=14.0+-0.5mm

----------

L=14.0+-0.5mm

----------

L=14.0+-0.5mm

----------

L=14.0+-0.5mm

Information:

Test

Set up as illustrated and turn the alternator to measure vacuum pump performance. If the measurement is lower than nominal values, disassemble and check for broken vane, traces of interference on housing, rotor and plate surfaces. Replace if defective.Ultimate vacuum Exhaust characteristics after 20 seconds 4.9 Safety Relay

(1) R8T30171 Safety Relay Inspection Measure voltage at each terminal in the sequence shown below to identify faulty parts.(a) On-vehicle Test (b) Component TestThe resistance value between terminals "R" and "L" shall be within specified range.(2) Inspection by RX-Q30 Safety Relay Continuity Tester Check between terminals marked with * applying 15 to 17 V between "K" and "E" terminals.4.10 Preheater

Intake air heater

(1) Removal and installation (Refer to Group 15 Intake and Exhaust.)(2) Inspection Perform the following inspection and check the function of each part or the wiring if necessary.(a) Time required before indicator becomes red-hot: Standard timeNominal value 40 to 60 seconds (ME037260, ME037197:1.83 kW)20 to 30 seconds (ME077014, ME077015:2.86 kW)(b) Check each terminal of the air heater for looseness and the heater element for damage and contact with other parts.Heater relay

Inspection (1) Check to ensure that there is continuity between the terminals "B" and "S" when 2.3 A (24 V type) or 5.2 A (12 V type) exciting current is applied between terminal "SW" in the illustration and body ground.(2) Check also the heater relay fuse and replace if it has been burnt out. When replacing fuses, be sure to use a fuse of specified capacity.4.11 Automatic Stop Device

Energize-to-stop type

(1) Stop solenoid (a) Connect the stop lever and solenoid using the rod and remove the solenoid cover.(b) Push manually the stop lever to the stop position and adjust the rod so that the solenoid pointer gap becomes as specified.(c) Check that the stop lever to external stopper clearance is as specified when the stop lever is on the operation side.(d) In the state of (c) above, apply specified voltage to solenoid "B" terminal and check that the pointer gap and ammeter reading are as specified. (Stop lever stop side)(e) Tighten the lock nut of the rod.(f) Check that the solenoid pointer color has not changed and then install the cover.(2) Solenoid relay Make connections as shown above and perform the following checks.(a) Oil pressure timerSet the snap switch A to ON. Operate a stop watch as soon as the snap switch B is set to ON, and measure the time required before the solenoid is operated.(b) Stop timerSet the snap switch B to OFF 5 seconds after the solenoid has been operated. At the same time, using a stop watch, measure the time required before the solenoid is reset.The snap switch B is set to OFF 5 seconds after operation of the solenoid because if the solenoid is operated, it takes 5 seconds before the alternator voltage disappears.(c) Manual stop timerWhen the push switch C (stop switch) is set to ON, the solenoid is operated. Operate a stop watch as soon as the stop switch C is set to

Set up as illustrated and turn the alternator to measure vacuum pump performance. If the measurement is lower than nominal values, disassemble and check for broken vane, traces of interference on housing, rotor and plate surfaces. Replace if defective.Ultimate vacuum Exhaust characteristics after 20 seconds 4.9 Safety Relay

(1) R8T30171 Safety Relay Inspection Measure voltage at each terminal in the sequence shown below to identify faulty parts.(a) On-vehicle Test (b) Component TestThe resistance value between terminals "R" and "L" shall be within specified range.(2) Inspection by RX-Q30 Safety Relay Continuity Tester Check between terminals marked with * applying 15 to 17 V between "K" and "E" terminals.4.10 Preheater

Intake air heater

(1) Removal and installation (Refer to Group 15 Intake and Exhaust.)(2) Inspection Perform the following inspection and check the function of each part or the wiring if necessary.(a) Time required before indicator becomes red-hot: Standard timeNominal value 40 to 60 seconds (ME037260, ME037197:1.83 kW)20 to 30 seconds (ME077014, ME077015:2.86 kW)(b) Check each terminal of the air heater for looseness and the heater element for damage and contact with other parts.Heater relay

Inspection (1) Check to ensure that there is continuity between the terminals "B" and "S" when 2.3 A (24 V type) or 5.2 A (12 V type) exciting current is applied between terminal "SW" in the illustration and body ground.(2) Check also the heater relay fuse and replace if it has been burnt out. When replacing fuses, be sure to use a fuse of specified capacity.4.11 Automatic Stop Device

Energize-to-stop type

(1) Stop solenoid (a) Connect the stop lever and solenoid using the rod and remove the solenoid cover.(b) Push manually the stop lever to the stop position and adjust the rod so that the solenoid pointer gap becomes as specified.(c) Check that the stop lever to external stopper clearance is as specified when the stop lever is on the operation side.(d) In the state of (c) above, apply specified voltage to solenoid "B" terminal and check that the pointer gap and ammeter reading are as specified. (Stop lever stop side)(e) Tighten the lock nut of the rod.(f) Check that the solenoid pointer color has not changed and then install the cover.(2) Solenoid relay Make connections as shown above and perform the following checks.(a) Oil pressure timerSet the snap switch A to ON. Operate a stop watch as soon as the snap switch B is set to ON, and measure the time required before the solenoid is operated.(b) Stop timerSet the snap switch B to OFF 5 seconds after the solenoid has been operated. At the same time, using a stop watch, measure the time required before the solenoid is reset.The snap switch B is set to OFF 5 seconds after operation of the solenoid because if the solenoid is operated, it takes 5 seconds before the alternator voltage disappears.(c) Manual stop timerWhen the push switch C (stop switch) is set to ON, the solenoid is operated. Operate a stop watch as soon as the stop switch C is set to

Have questions with 104742-1031?

Group cross 104742-1031 ZEXEL

Isuzu

104742-1031

8944046181

INJECTION-PUMP ASSEMBLY

4BE1F

4BE1F