Information injection-pump assembly

ZEXEL

104742-0011

1047420011

MAZDA

SLG113800A

slg113800a

Rating:

Cross reference number

ZEXEL

104742-0011

1047420011

MAZDA

SLG113800A

slg113800a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

65.1

64.6

65.6

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Injection timing adjustment_02

Pump speed

r/min

400

390

410

Average injection quantity

mm3/st.

78.6

78.6

78.6

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

625

615

635

Average injection quantity

mm3/st.

54.2

54.2

54.2

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

990

1010

Average injection quantity

mm3/st.

65.1

64.1

66.1

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1600

1590

1610

Average injection quantity

mm3/st.

75.6

75.6

75.6

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1875

1875

1875

Average injection quantity

mm3/st.

57.5

54.5

60.5

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Injection quantity adjustment_02

Pump speed

r/min

2200

2200

2200

Average injection quantity

mm3/st.

8

Oil temperature

degC

52

50

54

Remarks

OFF

OFF

Injection quantity adjustment_03

Pump speed

r/min

1875

1865

1885

Average injection quantity

mm3/st.

57.5

54

61

Difference in delivery

mm3/st.

7.5

Oil temperature

degC

50

48

52

Injection quantity adjustment_04

Pump speed

r/min

1950

1940

1960

Average injection quantity

mm3/st.

25.5

25.5

25.5

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

365

365

365

Average injection quantity

mm3/st.

12.3

11.3

13.3

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Remarks

OFF

OFF

Governor adjustment_02

Pump speed

r/min

365

355

375

Average injection quantity

mm3/st.

12.3

10.8

13.8

Difference in delivery

mm3/st.

3

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

75

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

90

110

Average injection quantity

mm3/st.

75

75

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1500

1500

1500

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1500

1500

1500

Pressure with S/T OFF

kPa

520

500

540

Pressure with S/T OFF

kgf/cm2

5.3

5.1

5.5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1500

1490

1510

Pressure with S/T OFF

kPa

520

500

540

Pressure with S/T OFF

kgf/cm2

5.3

5.1

5.5

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1500

1500

1500

Timer stroke with S/T OFF

mm

2.4

2.2

2.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1500

1490

1510

Timer stroke with S/T OFF

mm

2.4

2

2.8

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1600

1590

1610

Timer stroke with S/T OFF

mm

3.1

2.6

3.6

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1690

1710

Timer stroke with S/T OFF

mm

3.3

2.8

3.9

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.1

3

3.2

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

40

36

44

Control lever angle beta

deg.

35

32

38

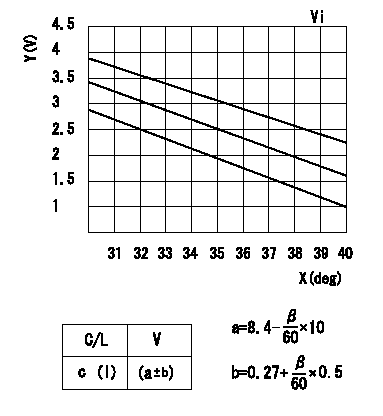

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Potentiometer adjustment

Adjust the potentiometer so that the output voltage is V1 at the full speed position.

With the control lever turned from the idle position to the full speed position, connect the connector wiring so that voltage increases

With the control lever in the idle position, confirm that the output voltage is within the range shown in the graph. Record the output voltage.

Vi:Applied voltage

Y:Output voltage a

X:Angle beta

C/L: lever position

I:Idle

V:Output voltage

----------

Vi=10V V1=8.4+-0.03V

----------

Vi=10V c=0deg

----------

Vi=10V V1=8.4+-0.03V

----------

Vi=10V c=0deg

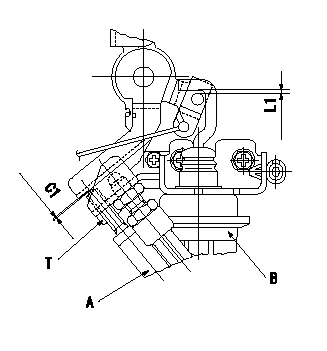

0000001901 V-FICD ADJUSTMENT

Temperature adjustment stopper adjustment

At the idle position, adjust so that the clearance between the control lever and the temperature adjustment stopper C1.

Adjustment of the V-FICD

Move the bracket in the direction of the arrow to adjust the clearance between the V-actuator rod and the control lever pin to L1.

A:Temperature adjustment stopper

B:V-actuator

----------

C1=0.3+-0.1mm L1=2+0.5mm

----------

C1=0.3+-0.1mm L1=2+0.5mm T=9.8~12.7N-m(1~1.3kgf-m)

----------

C1=0.3+-0.1mm L1=2+0.5mm

----------

C1=0.3+-0.1mm L1=2+0.5mm T=9.8~12.7N-m(1~1.3kgf-m)

Information:

Coolant is essential to control engine operating temperatures and make components last longer. Poorly maintained coolant can actually shorten component life by causing a chain reaction of heat problems. Excessive heat can cause: * Hot spots that crack steel, notably in cylinder heads* Bubble pockets that form on cylinder surfaces and result in liner pitting* Oil to degrade, leading to component damage* Lacquer and shellac build up on precision hydraulic parts* Oil additives to break down and transmission clutches to slipS O S Coolant Analysis is the best way to monitor the condition of your coolant and your cooling system. The two level program, based on samples you submit, shows the condition of coolant and the cooling system.Level I: Basic Coolant Maintenance Check

Checks for correct chemical balance for proper heat and corrosion control. Tests for: * glycol* SCA concentrations* pH* conductivityS O S Coolant Analysis reports results and makes recommendations, usually within 24 hours.The concentration of SCA should be checked regularly for overconcentration or underconcentration. This should be done with test kits, or S O S Coolant Analysis (Level I) at the Every 250 Service Hours interval.Further coolant analysis is recommended at twice a year or after every 1000 service hours.For example, suppose considerable deposits are found in the water jacket areas on the external cooling system, yet coolant additive concentrations were carefully maintained. Chances are that the coolant water had minerals which deposited on the engine over time.One way to verify the water condition, or to be sure of new water at fill time, is to have a coolant analysis conducted. Full water analysis can sometimes be obtained locally by contacting your local water utility company or an agricultural agent. Private laboratories are also available.Caterpillar recommends S O S Level II Coolant Analysis.Level II: Comprehensive Cooling System Analysis

Completely analyzes coolant and coolant effects on the cooling system. Level II Analysis provides: * full Level I analysis* visual properties inspection* metal corrosion and contaminant identification* identification of built up impurities that point to corrosion and scaling problems BEFORE they lead to costly repairs.Level II Analysis provides a simple, clear report of results, and makes recommendations for the lowest cost corrective options.For more information of coolant analysis and how it can help manage your equipment, see your Caterpillar dealer. Consult your Caterpillar dealer for complete information and assistance in establishing an S O S analysis program for your engine(s).

Checks for correct chemical balance for proper heat and corrosion control. Tests for: * glycol* SCA concentrations* pH* conductivityS O S Coolant Analysis reports results and makes recommendations, usually within 24 hours.The concentration of SCA should be checked regularly for overconcentration or underconcentration. This should be done with test kits, or S O S Coolant Analysis (Level I) at the Every 250 Service Hours interval.Further coolant analysis is recommended at twice a year or after every 1000 service hours.For example, suppose considerable deposits are found in the water jacket areas on the external cooling system, yet coolant additive concentrations were carefully maintained. Chances are that the coolant water had minerals which deposited on the engine over time.One way to verify the water condition, or to be sure of new water at fill time, is to have a coolant analysis conducted. Full water analysis can sometimes be obtained locally by contacting your local water utility company or an agricultural agent. Private laboratories are also available.Caterpillar recommends S O S Level II Coolant Analysis.Level II: Comprehensive Cooling System Analysis

Completely analyzes coolant and coolant effects on the cooling system. Level II Analysis provides: * full Level I analysis* visual properties inspection* metal corrosion and contaminant identification* identification of built up impurities that point to corrosion and scaling problems BEFORE they lead to costly repairs.Level II Analysis provides a simple, clear report of results, and makes recommendations for the lowest cost corrective options.For more information of coolant analysis and how it can help manage your equipment, see your Caterpillar dealer. Consult your Caterpillar dealer for complete information and assistance in establishing an S O S analysis program for your engine(s).