Information injection-pump assembly

ZEXEL

104741-8121

1047418121

MITSUBISHI

ME444303

me444303

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

High Pressure Diesel Pump 321-4936 ME444303 104741-8122, Compatible For 306 307B/C/D 308C/D 4M40 Engines, Direct Fit Excavator Fuel System Assembly

Sdvbfjnm 【Compatible Models】: Compatible For excavator models 306, 307B/C/D, 308C/D 4M40 diesel engines, ensuring precise high-pressure fuel delivery and system compatibility. || 【Direct Replacement】: Engineered to match original specifications seamless installation and stable fuel pressure performance. || 【Durable Design】: Constructed reinforced alloy materials to withstand extreme pressure and harsh construction site environments. || 【OME Compliance】: Rigorously tested to meet OME 321-4936 ME444303 104741-8122 standards durability and fuel efficiency. || 【Universal Application】: Supports reliable fuel supply excavators in both construction and industrial operations.

Sdvbfjnm 【Compatible Models】: Compatible For excavator models 306, 307B/C/D, 308C/D 4M40 diesel engines, ensuring precise high-pressure fuel delivery and system compatibility. || 【Direct Replacement】: Engineered to match original specifications seamless installation and stable fuel pressure performance. || 【Durable Design】: Constructed reinforced alloy materials to withstand extreme pressure and harsh construction site environments. || 【OME Compliance】: Rigorously tested to meet OME 321-4936 ME444303 104741-8122 standards durability and fuel efficiency. || 【Universal Application】: Supports reliable fuel supply excavators in both construction and industrial operations.

Compatible With 306 307B C D 308C D Fuel Pump 4M40 High Pressure Diesel Pump 321-4936 ME444303 104741-8122 Excavator Parts

QEDFGH Dependable Diesel Injection Pump || This diesel injection pump is designed to deliver consistent fuel flow, supporting stable engine operation. It is compatible with a variety of diesel engines and suited Compatible With regular use. || Quality Craftsmanship || Made from robust materials, this diesel fuel pump is built to handle regular wear and tear, providing reliable functionality Compatible With your vehicle or equipment. || Steady Fuel Delivery || This pump ensures even fuel distribution, helping to maintain consistent engine operation and smoother functionality. || Simple Installation and Wide Fitment || Designed Compatible With easy setup, this diesel injection pump Compatible With a range of models and makes, making it a practical choice Compatible With repairs or replacements. || Supports Engine PerCompatible Withmance || By maintaining stable fuel pressure and flow, this pump aids in reliable engine operation and starting, even in varying conditions.

QEDFGH Dependable Diesel Injection Pump || This diesel injection pump is designed to deliver consistent fuel flow, supporting stable engine operation. It is compatible with a variety of diesel engines and suited Compatible With regular use. || Quality Craftsmanship || Made from robust materials, this diesel fuel pump is built to handle regular wear and tear, providing reliable functionality Compatible With your vehicle or equipment. || Steady Fuel Delivery || This pump ensures even fuel distribution, helping to maintain consistent engine operation and smoother functionality. || Simple Installation and Wide Fitment || Designed Compatible With easy setup, this diesel injection pump Compatible With a range of models and makes, making it a practical choice Compatible With repairs or replacements. || Supports Engine PerCompatible Withmance || By maintaining stable fuel pressure and flow, this pump aids in reliable engine operation and starting, even in varying conditions.

Compatible With 306 307B C D 308C D Fuel Pump 4M40 High Pressure Diesel Pump 321-4936 ME444303 104741-8122 Excavator Parts

IUVPTAF The performance of high-pressure fuel pumps is strong, reflected in efficient atomization, rapid response, and precise fuel supply || Stable pressure, one-way valve and buffer at the oil outlet to prevent fuel backflow and reduce oil pressure pulse || Equipped with safety valves and pressure limiters to achieve multiple protections. Can work stably in complex environments || Integrated design, energy-saving and environmentally friendly, reduces fuel consumption, and the fuel pump also achieves intelligent control || Compatible With 306 307B C D 308C D Fuel Pump 4M40 High Pressure Diesel Pump 321-4936 ME444303 104741-8122 Excavator Parts

IUVPTAF The performance of high-pressure fuel pumps is strong, reflected in efficient atomization, rapid response, and precise fuel supply || Stable pressure, one-way valve and buffer at the oil outlet to prevent fuel backflow and reduce oil pressure pulse || Equipped with safety valves and pressure limiters to achieve multiple protections. Can work stably in complex environments || Integrated design, energy-saving and environmentally friendly, reduces fuel consumption, and the fuel pump also achieves intelligent control || Compatible With 306 307B C D 308C D Fuel Pump 4M40 High Pressure Diesel Pump 321-4936 ME444303 104741-8122 Excavator Parts

Cross reference number

ZEXEL

104741-8121

1047418121

MITSUBISHI

ME444303

me444303

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.8

63.3

64.3

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

63.2

59.2

67.2

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

62.6

58.6

66.6

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

63.8

62.8

64.8

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

64.6

62.1

67.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1125

1125

1125

Average injection quantity

mm3/st.

23.9

21.4

26.4

Difference in delivery

mm3/st.

7.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1125

1125

1125

Average injection quantity

mm3/st.

23.9

20.9

26.9

Difference in delivery

mm3/st.

8

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

540

540

540

Average injection quantity

mm3/st.

19.6

17.6

21.6

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment_02

Pump speed

r/min

540

540

540

Average injection quantity

mm3/st.

19.6

17.1

22.1

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

145

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

145

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

540

540

540

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

710

580

840

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

559

539

579

Pressure

kgf/cm2

5.7

5.5

5.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

800

800

800

Pressure

kPa

520

471

569

Pressure

kgf/cm2

5.3

4.8

5.8

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

900

900

900

Pressure

kPa

559

530

588

Pressure

kgf/cm2

5.7

5.4

6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1000

1000

1000

Pressure

kPa

598

549

647

Pressure

kgf/cm2

6.1

5.6

6.6

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.3

1.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke

mm

1.5

1.1

1.9

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.5

1.9

3.1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

2.9

2.4

3.3

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

2

1.9

2.1

Control lever angle alpha

deg.

57

53

61

Control lever angle beta

deg.

25

20

30

Test data Ex:

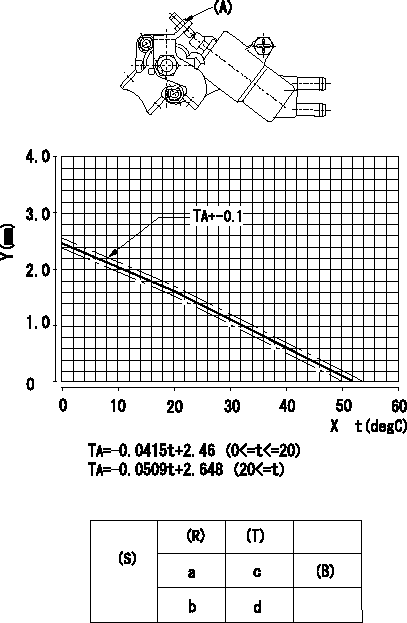

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjust the timer stroke

1. Adjust the timer stroke B so that it is as described in the graph. (graph TA)

2) Adjust using screw (A) to obtain the timer stroke determined in step 1.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(S) Cold advance

(R) Cooling water temperature (deg C)

(T) Timer piston stroke (mm)

(B) Standard point

----------

----------

a=20degC b=0degC c=1.63+-4mm d=2.46+-0.6mm

----------

----------

a=20degC b=0degC c=1.63+-4mm d=2.46+-0.6mm

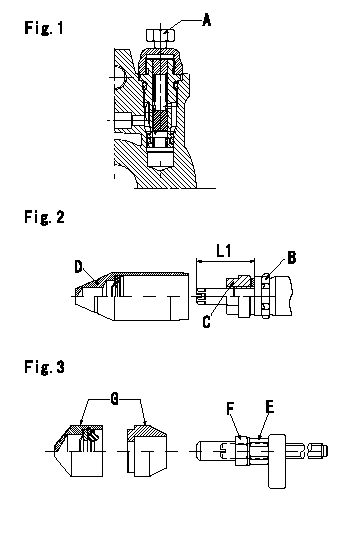

0000001901 TAMPER PROOF

Tamperproof installation procedure

A:Position of break

B:Rubber vibration damper

C:Nut

D:Cap

E:Nut

F:Nut

G:Cap

L1:Inspection dimension

Fig. 1 Regulating valve seal

1) Target breaking torque T1

2) Maximum allowable breaking torque T2

3) Because the cap and the regulating valve are fixed using the MEC process, the bolt cannot be loosened after the bolt has been broken.

Fig.2 Full load adjusting screw

1) Confirm the position of the rubber vibration damper (B) and then tighten nut (C) to the torque T3.

Fig. 3 Maximum speed adjusting screw

1) Tighten nut (E) to the torque T4.

2) To prevent nut (E) from turning together, fix (E) using the tool, then tighten nut (F) to torque T4.

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm

----------

L1=23~28mm T1=5~6.9N-m(0.5~0.69kgf-m) T2=9N-m(0.9kgf-m) T3=7~9N-m(0.7~0.9kgf-m) T4=6~9N-m(0.6~0.9kgf-m)

----------

L1=23~28mm

Information:

TECHNICAL INFORMATION BULLETIN JAN. 15th, 2003

EXCAVATORS

WHEEL LOADERS

ENGINES 322C: (EMR, MAR);

325C: (CRB, CSJ, JLC, JLD, DTF)

950G II: (AYL, AYB);

962G II: (AYE, BAB)

3126B: (BMA)

Component Code(s) 1408SUBJECT: A NEW INJECTION ACTUATION PRESSURE CONTROL VALVE CONNECTOR INCREASES ENGINE OPERATION

PROBLEM:

The injection actuation pressure (IAP) control valve connector may have been assembled incorrectly on some 3126B engine harnesses. This can lead to intermittent engine operation or can cause the engine to stop.

SOLUTION:

If your machine exhibits symptoms of intermittent engine operation or abruptly stopping, the IAP control valve connector should be disconnected from the machine, examined for solenoid contact problems and re-installed using a correct procedure.

Procedure for installing the IAP control valve connector

This procedure will describe how to properly install the 232-4367 Harness.

Required Parts

Qty Part Number Description

1 232-4367 Harness

Procure the part that is listed in the table.

Illustration 1. Left Side of a 3126B Engine on a D6N.

(1) IAP Control Valve

(2) IAP Control Valve Connector

Note: Illustration 1 is from a D6N that is equipped with a 3126B for photographical purposes. The location of the IAP Control Valve is the same for your machine.

Disconnect the IAP control valve connector (2) from the IAP Control Valve (1). See Illustration 1.

Cut the two wires directly behind the connector.

Using wire strippers, strip the ends of the two wires.

Install the 232-4367 Harness, by crimping the stripped wires inside the splice.

Note: Take care to connect the pink wire to the pink wire on one hand and the purple wire to the purple wire on the other hand.

Heat both heat shrinkable tubes in order to insulate both the splices.

Reconnect the repaired harness to the IAP Control Valve (1).

COPYRIGHT 2003 CATERPILLAR

ALL RIGHTS RESERVED