Information injection-pump assembly

BOSCH

F 01G 09W 0E2

f01g09w0e2

ZEXEL

104741-7480

1047417480

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$1,230.00

31 Jan 2023

0.0022[0.00] pounds

CN: SFGU SHOP

ReadJade Fuel Pump Fit for ZEXEL Fuel Injection Pump 104641-7480 104741-7480 Diesel Fuel Pump NP-VE4/11F1800LNP2593 Replacement Parts

ReadJade Fit For ZEXEL Fuel Injection Pump 104641-7480 104741-7480 Diesel Fuel Pump NP-VE4/11F1800LNP2593 || Material Type: Stainless Steel

ReadJade Fit For ZEXEL Fuel Injection Pump 104641-7480 104741-7480 Diesel Fuel Pump NP-VE4/11F1800LNP2593 || Material Type: Stainless Steel

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-7480 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | 479766-0620 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0400 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-1920 | DRIVE SHAFT |

| 12/1. | [1] | 146200-1900 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 12/5. | [1] | 146206-0400 | COILED SPRING |

| 17. | [1] | 146204-0100 | PLAIN WASHER |

| 20. | [1] | 146210-7720 | ROLLER SET |

| 24. | [1] | 146303-0400 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0301 | SLOTTED WASHER |

| 29. | [1] | 146220-7220 | CAM PLATE |

| 30. | [1] | 146600-6200 | GASKET |

| 31. | [1] | 146300-5700 | PUMP PLUNGER |

| 32. | [1] | 146301-0500 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM |

| 34. | [1] | 146306-1100 | COMPRESSION SPRING |

| 34B. | [1] | 146302-4200 | COMPRESSION SPRING |

| 34C. | [1] | 146302-2800 | COMPRESSION SPRING K=2.50KG/MM |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-6200 | GASKET |

| 37. | [1] | 146310-0000 | COVER |

| 38. | [2] | 146622-0300 | BLEEDER SCREW |

| 39. | [1] | 146310-5500 | COVER |

| 40. | [2] | 146622-0300 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0800 | GUIDE PIN |

| 50. | [1] | 146402-5220 | HYDRAULIC HEAD |

| 50. | [1] | 146402-5220 | HYDRAULIC HEAD |

| 50. | [1] | 146402-5220 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET |

| 58. | [4] | 149300-0521 | PRESSURE-CONTROL VALVE |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146753-4720 | COMPENSATOR,MANIFOLD-PRES |

| 67/1. | [1] | 146806-8120 | GOVERNOR COVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/23. | [1] | 146936-1900 | BRACKET |

| 67/24. | [2] | 139006-4500 | BLEEDER SCREW |

| 67/31. | [1] | 146710-0700 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-0700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET |

| 67/39. | [1] | 146620-9500 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET |

| 67/41. | [1] | 146713-4300 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0200 | PLATE |

| 67/43. | [1] | 146715-0300 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-5500 | COILED SPRING |

| 67/48/1. | [1] | 146720-3000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-3100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-3200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-3300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-3400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-3500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-3600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-3700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-3800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-3900 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-4000 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146720-4100 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146720-4200 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146720-4300 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146720-4400 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146720-8900 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146720-9000 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146720-9100 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146720-9200 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146720-9300 | SPACER BUSHING L7.5 |

| 67/48/1. | [1] | 146720-9400 | SPACER BUSHING L7.7 |

| 67/48/1. | [1] | 146720-9500 | SPACER BUSHING L7.9 |

| 67/48/1. | [1] | 146720-9600 | SPACER BUSHING L8.1 |

| 67/48/1. | [1] | 146720-9700 | SPACER BUSHING L8.3 |

| 67/48/1. | [1] | 146720-9800 | SPACER BUSHING L8.5 |

| 67/48/1. | [1] | 146720-9900 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146725-0000 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146725-0100 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146725-0200 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146725-0300 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146725-0400 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146725-0500 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146725-0600 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146725-0700 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146725-0800 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146725-0900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146725-1000 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-1100 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-1200 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-1300 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-1400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-1500 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-1600 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-1700 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-1800 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-1900 | SPACER BUSHING L7.6 |

| 67/48/1. | [1] | 146725-2000 | SPACER BUSHING L7.8 |

| 67/48/1. | [1] | 146725-2100 | SPACER BUSHING L8.0 |

| 67/48/1. | [1] | 146725-2200 | SPACER BUSHING L8.2 |

| 67/48/1. | [1] | 146725-2300 | SPACER BUSHING L8.4 |

| 67/48/1. | [1] | 146725-2400 | SPACER BUSHING L8.6 |

| 67/49. | [1] | 146721-3720 | COVER |

| 67/50. | [1] | 146722-0200 | FLAT-HEAD SCREW |

| 67/51. | [1] | 146600-0300 | O-RING |

| 67/53. | [1] | 013020-6040 | UNION NUT |

| 67/54. | [2] | 139006-4500 | BLEEDER SCREW |

| 67/55. | [2] | 139006-4800 | BLEEDER SCREW |

| 67/56. | [1] | 146723-1120 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146935-6000 | BRACKET STAMP 560 |

| 67/68. | [1] | 139006-4400 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/83. | [1] | 146717-4200 | COILED SPRING |

| 67/98. | [2] | 146648-2800 | SPACER BUSHING |

| 67/112. | [1] | 146934-9920 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146811-2220 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146833-0300 | CONTROL LEVER |

| 72B. | [1] | 146833-0400 | CONTROL LEVER |

| 72C. | [1] | 146833-0500 | CONTROL LEVER |

| 72D. | [1] | 146833-0600 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 013020-6040 | UNION NUT |

| 95. | [1] | 146855-0720 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-2600 | PLAIN WASHER |

| 115. | [1] | 146975-8800 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG L5.6 |

| 117/1. | [1] | 146877-4800 | PLUG L5.7 |

| 117/1. | [1] | 146877-4900 | PLUG L5.8 |

| 117/1. | [1] | 146877-5000 | PLUG L5.9 |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-1620 | CAPSULE |

| 130/2. | [1] | 146422-1100 | BLEEDER SCREW |

| 130/3. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0920 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146688-3220 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-4901 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 159. | [1] | 146625-8000 | PLATE |

| 160. | [1] | 020105-0940 | BLEEDER SCREW |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 206. | [1] | 013121-4140 | UNION NUT |

| 207. | [1] | 029321-4050 | LOCKING WASHER |

| 220. | [1] | 146587-1100 | COILED SPRING |

| 233. | [1] | 146658-8920 | WIRE |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146658-7320 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0400 | EYE BOLT |

| 247. | [1] | 146677-9520 | INLET UNION |

| 247. | [1] | 146677-9520 | INLET UNION |

| 248. | [1] | 146649-7400 | SPACER BUSHING |

| 251. | [1] | 146125-0101 | FILTER |

| 252. | [1] | 146125-0200 | COILED SPRING |

| 260. | [1] | 146611-2121 | BRACKET |

| 261. | [2] | 146621-4700 | UNION NUT |

| 262. | [1] | 139008-0900 | BLEEDER SCREW |

| 264. | [1] | 016500-5010 | O-RING |

| 310. | [1] | 146685-6720 | POTENTCIOMETER |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146648-2900 | JOINT CONNECTION |

| 310/4B. | [1] | 146648-3000 | JOINT CONNECTION |

| 310/4C. | [1] | 146648-3100 | JOINT CONNECTION |

| 310/4D. | [1] | 146648-3200 | JOINT CONNECTION |

| 310/4E. | [1] | 146648-3300 | JOINT CONNECTION |

| 310/4F. | [1] | 146648-4700 | JOINT CONNECTION |

| 310/4G. | [1] | 146648-5300 | JOINT CONNECTION |

| 310/4H. | [1] | 146649-1700 | JOINT CONNECTION |

| 310/4I. | [1] | 146649-7700 | JOINT CONNECTION |

| 310/4K. | [1] | 146649-7900 | JOINT CONNECTION |

| 310/4M. | [1] | 146649-8100 | JOINT CONNECTION |

| 310/4O. | [1] | 146649-8300 | JOINT CONNECTION |

| 310/4P. | [1] | 146649-9400 | JOINT CONNECTION |

| 310/5. | [1] | 146661-0601 | BOOT |

| 800S. | [1] | 146020-0320 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-1320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0920 | PARTS SET |

| 810S. | [1] | 146600-6320 | REPAIR SET |

| 812S. | [1] | 146600-1920 | PARTS SET |

| 821S. | [1] | 146210-7820 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 839S. | [1] | 146421-1820 | CAPSULE |

| 903. | [1] | 479766-0620 | PULSE GENERATOR |

| 903/6. | [1] | 479773-6500 | O-RING |

| 906. | [1] | 146984-6700 | NAMEPLATE |

Include in #2:

104741-7480

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 09W 0E2

f01g09w0e2

ZEXEL

104741-7480

1047417480

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Timer measuring device installation position

Low pressure side LOW PRESSURE SIDE

Low pressure side LOW PRESSURE SIDE

Injection timing adjustment

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

71.4

70.9

71.9

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

105.5

105

106

Difference in delivery

mm3/st.

8.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

126.1

125.6

126.6

Difference in delivery

mm3/st.

10.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

71.4

69.4

73.4

Difference in delivery

mm3/st.

8

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

800

800

800

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Average injection quantity

mm3/st.

105.5

103.5

107.5

Difference in delivery

mm3/st.

9

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

126.1

124.1

128.1

Difference in delivery

mm3/st.

11

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

128.7

121.7

135.7

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

136.9

129.4

144.4

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

30.7

27.7

33.7

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

30.7

27.7

33.7

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

16.3

14.3

18.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

16.3

14.3

18.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

107.2

87.2

127.2

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

107.2

87.2

127.2

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Overflow quantity with S/T ON

cm3/min

990

760

1220

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

549

520

578

Pressure with S/T OFF

kgf/cm2

5.6

5.3

5.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

800

800

800

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T ON

kPa

510

451

569

Pressure with S/T ON

kgf/cm2

5.2

4.6

5.8

Pressure with S/T OFF

kPa

432

393

471

Pressure with S/T OFF

kgf/cm2

4.4

4

4.8

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

500

461

539

Pressure with S/T OFF

kgf/cm2

5.1

4.7

5.5

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T ON

kPa

579

520

638

Pressure with S/T ON

kgf/cm2

5.9

5.3

6.5

Pressure with S/T OFF

kPa

510

471

549

Pressure with S/T OFF

kgf/cm2

5.2

4.8

5.6

Oil temperature

degC

50

48

52

Stop lever angle_05

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

549

520

578

Pressure with S/T OFF

kgf/cm2

5.6

5.3

5.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_06

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

618

579

657

Pressure with S/T OFF

kgf/cm2

6.3

5.9

6.7

Oil temperature

degC

50

48

52

Stop lever angle_07

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

657

618

696

Pressure with S/T OFF

kgf/cm2

6.7

6.3

7.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

4

3.8

4.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T ON

mm

4.2

3.4

5

Timer stroke with S/T OFF

mm

3

2.4

3.6

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1200

1200

1200

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

4

3.6

4.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_04

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

4.9

4.3

5.5

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

4.9

4.3

5.5

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

91.6

91.1

92.1

Timer stroke TA

mm

2.5

2.5

2.5

Timer stroke variation dT

mm

0.5

0.3

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

91.6

88.6

94.6

Timer stroke TA

mm

2.5

2.5

2.5

Timer stroke variation dT

mm

0.5

0.1

0.9

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

57.1

54.1

60.1

Timer stroke TA

mm

1.5

Timer stroke variation dT

mm

1.5

1.5

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.6

3.5

3.7

KF dimension

mm

7.7

7.6

7.8

MS dimension

mm

0.5

0.4

0.6

BCS stroke

mm

6.8

6.6

7

Pre-stroke

mm

0.2

0.18

0.22

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

40

35

45

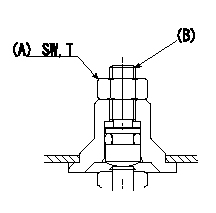

Test data Ex:

0000001601 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=800r/min N2=600r/min P1=40.0kPa(300mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=800r/min N2=600r/min P1=40.0kPa(300mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

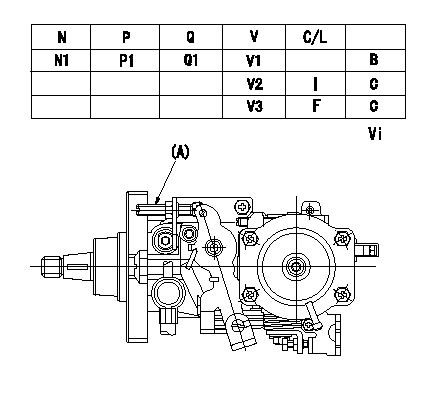

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Adjustment method [supply voltage Vi, dummy bolt (A)]

1. Hold the dummy bolt (A) against the control lever at position N = N1 and Q = Q1 and fix using the lock nut.

2. When adjusting the potentiometer, position the control lever to contact the dummy bolt (A).

Adjust the potentiometer so that the output voltage is V1.

3. After completing adjustment remove the dummy bolt (A). Confirm that the potentiometer output voltage is as specified at the control lever idle position and full position.

Dummy bolt and nut part number: corresponding to 146526-3300 (bolt) 42 (mm)

Corresponding to 013020-6040 (nut)

N:Pump speed

Q:Injection quantity

P:Boost pressure

V:Output voltage

C/L: control lever position

B:Adjusting point

C:Checking point

Vi:Applied voltage

I:Idling lever position

F:Full speed lever position

----------

N1=1000r/min Q1=43.2+-1.0mm3/st V1=4.04+-0.03V

----------

N1=1000r/min Q1=43.2+-1.0mm3/st P1=80.0kPa(600mmHg) V1=4.04+-0.03V V2=(1.62+-0.84V) V3=(8.28+-0.93V) Vi=10V

----------

N1=1000r/min Q1=43.2+-1.0mm3/st V1=4.04+-0.03V

----------

N1=1000r/min Q1=43.2+-1.0mm3/st P1=80.0kPa(600mmHg) V1=4.04+-0.03V V2=(1.62+-0.84V) V3=(8.28+-0.93V) Vi=10V

Information:

After the engine starts, and at frequent intervals while the engine is operating, the gauges should be observed. Determine the normal reading for each gauge. Investigate the cause whenever there is a significant change in the reading.Gauges

Tachometer

The tachometer indicates engine RPM. The high idle RPM and the full load RPM are stamped on the engine's information plate. The engine can be operated between these two speed limits for long periods of time without shortening engine life. Prolonged operation at high idle with little or no load can cause adverse engine operation. Engine Oil Pressure

If the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Observe the oil level. Maintain the oil level between the ADD and FULL mark on the dipstick. If the reading continues to fluctuate when the oil level is correct, stop engine and call your Caterpillar dealer. Engine Jacket Water Temperature

The engine should operate within the NORMAL (green) range. If the engine is operating in the (red) range and steam becomes apparent:1. Reduce the load and engine RPM.2. Inspect for coolant leaks.3. Determine if the engine must be shut down immediately; or if the engine can be safely cooled by reducing the load.See COOLING SYSTEM MAINTENANCE INSTRUCTIONS.

Do not add cold water to a hot engine: Cracking of engine components may occur. Allow the engine to cool, then add coolant.

If the temperature gauge reading registers in or near the cold range (white) while operating under load:1. Check the water temperature gauge for accuracy.2. Check the temperature regulators for proper temperature range. Replace regulators if necessary.See COOLING SYSTEM MAINTENANCE for DETAILS. Fuel pressure

If the fuel filter gauge registers in the OUT range, clean the primary fuel filter, if so equipped. Install new secondary or final fuel filter elements if gauge still registers OUT. See the FUEL MAINTENANCE INSTRUCTIONS and FUEL SPECIFICATIONS. Ammeter:

The ammeter reading is normal when the indicator is at or on the (+) side of zero, when the engine is running at rated speed. If indicator is to the left (-) side of zero, investigate and correct cause. Air Cleaner Service Indicator

When the gauge indicator locks in the red range, service the air cleaner. With the engine stopped; see AIR INDUCTION AND EXHAUST SYSTEM MAINTENANCE INSTRUCTIONS. Calibrated Gauges

Calibrated gauges are used on some engines to monitor the engine systems. If an abnormal engine condition develops, determine and analyze and correct the cause before a failure and downtime occurs.The operating limits given in the "OPERATING RANGES FOR ENGINES" chart are based on the engine running at continuous rated speed and load, after warm-up, using SAE 30, oil. If any of the gauges register at or outside the operating limits, investigate and correct any malfunction. See TROUBLESHOOTING GUIDE for guidance.

Shut the engine down if work on or around the engine is required.

DO NOT OPERATE THE ENGINE WITH THE GAUGES REGISTERING AT OR OUTSIDE THE LIMITS.

1. Tachometer.2. Left inlet manifold temperature.3. Right inlet manifold temperature.4. Left and right exhaust manifold

Tachometer

The tachometer indicates engine RPM. The high idle RPM and the full load RPM are stamped on the engine's information plate. The engine can be operated between these two speed limits for long periods of time without shortening engine life. Prolonged operation at high idle with little or no load can cause adverse engine operation. Engine Oil Pressure

If the gauge reading fluctuates after the load is stable:1. Remove the load.2. Reduce engine speed to low idle.3. Observe the oil level. Maintain the oil level between the ADD and FULL mark on the dipstick. If the reading continues to fluctuate when the oil level is correct, stop engine and call your Caterpillar dealer. Engine Jacket Water Temperature

The engine should operate within the NORMAL (green) range. If the engine is operating in the (red) range and steam becomes apparent:1. Reduce the load and engine RPM.2. Inspect for coolant leaks.3. Determine if the engine must be shut down immediately; or if the engine can be safely cooled by reducing the load.See COOLING SYSTEM MAINTENANCE INSTRUCTIONS.

Do not add cold water to a hot engine: Cracking of engine components may occur. Allow the engine to cool, then add coolant.

If the temperature gauge reading registers in or near the cold range (white) while operating under load:1. Check the water temperature gauge for accuracy.2. Check the temperature regulators for proper temperature range. Replace regulators if necessary.See COOLING SYSTEM MAINTENANCE for DETAILS. Fuel pressure

If the fuel filter gauge registers in the OUT range, clean the primary fuel filter, if so equipped. Install new secondary or final fuel filter elements if gauge still registers OUT. See the FUEL MAINTENANCE INSTRUCTIONS and FUEL SPECIFICATIONS. Ammeter:

The ammeter reading is normal when the indicator is at or on the (+) side of zero, when the engine is running at rated speed. If indicator is to the left (-) side of zero, investigate and correct cause. Air Cleaner Service Indicator

When the gauge indicator locks in the red range, service the air cleaner. With the engine stopped; see AIR INDUCTION AND EXHAUST SYSTEM MAINTENANCE INSTRUCTIONS. Calibrated Gauges

Calibrated gauges are used on some engines to monitor the engine systems. If an abnormal engine condition develops, determine and analyze and correct the cause before a failure and downtime occurs.The operating limits given in the "OPERATING RANGES FOR ENGINES" chart are based on the engine running at continuous rated speed and load, after warm-up, using SAE 30, oil. If any of the gauges register at or outside the operating limits, investigate and correct any malfunction. See TROUBLESHOOTING GUIDE for guidance.

Shut the engine down if work on or around the engine is required.

DO NOT OPERATE THE ENGINE WITH THE GAUGES REGISTERING AT OR OUTSIDE THE LIMITS.

1. Tachometer.2. Left inlet manifold temperature.3. Right inlet manifold temperature.4. Left and right exhaust manifold