Information injection-pump assembly

ZEXEL

104741-6820

1047416820

ISUZU

8970126510

8970126510

Rating:

Cross reference number

ZEXEL

104741-6820

1047416820

ISUZU

8970126510

8970126510

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

40

39.5

40.5

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

39.7

39.7

39.7

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

38.1

38.1

38.1

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

40

39

41

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1175

1175

1175

Average injection quantity

mm3/st.

42.9

42.9

42.9

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

20

17

23

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1350

1350

1350

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

20

17

23

Difference in delivery

mm3/st.

4

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

19.9

17.9

21.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

19.9

17.9

21.9

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

47

53

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

50

47

53

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

800

800

800

Overflow quantity

cm3/min

290

160

420

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

800

800

800

Pressure

kPa

235

215

255

Pressure

kgf/cm2

2.4

2.2

2.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

800

800

800

Pressure

kPa

235

215

255

Pressure

kgf/cm2

2.4

2.2

2.6

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

800

800

800

Timer stroke

mm

1.1

0.9

1.3

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

650

650

650

Timer stroke

mm

0.5

0.1

1.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

800

800

800

Timer stroke

mm

1.1

0.9

1.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1175

1175

1175

Timer stroke

mm

2.4

2.1

2.8

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1.8

1.7

1.9

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

23

18

28

Test data Ex:

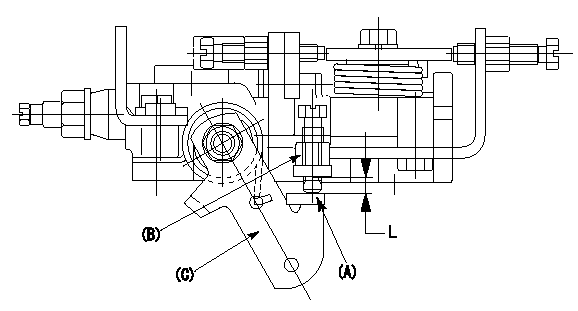

0000001801 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust the adjusting bolt A so that the starting injection quantity adjustment is within the standards. Fix using the nut B.

(C) Stop lever

L:Adjustment dimensions

----------

L=2~8.5mm

----------

L=2~8.5mm

----------

L=2~8.5mm

----------

L=2~8.5mm

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

Termination Date

March 31, 1997Problem

Improvements have been made to the remanufactured unit injectors that are used in various 3114 and 3116 Engines. All of the former 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors need to be removed from Parts Stock.

Action Required

Remove all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors from Parts Stock.

When ordering parts, refer to the attached chart until the information is available in a permanent publication.

Service Claim Allowances

Submit one claim for all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors removed from Parts Stock.

TEPS Dealers should refer to their warranty bullitin for proper claiming and disposition.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".

Attach.(1-UNIT INJECTOR CHART)3114 & 3116 Unit Injector Chart

Termination Date

March 31, 1997Problem

Improvements have been made to the remanufactured unit injectors that are used in various 3114 and 3116 Engines. All of the former 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors need to be removed from Parts Stock.

Action Required

Remove all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors from Parts Stock.

When ordering parts, refer to the attached chart until the information is available in a permanent publication.

Service Claim Allowances

Submit one claim for all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors removed from Parts Stock.

TEPS Dealers should refer to their warranty bullitin for proper claiming and disposition.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R3002, 0R3003, 0R3190, 0R3389, 0R3580, 0R3742, 0R4368, 0R4369, 0R4370, 0R4374, and 0R4376 Remanufactured Unit Injectors that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".

Attach.(1-UNIT INJECTOR CHART)3114 & 3116 Unit Injector Chart