Information injection-pump assembly

ZEXEL

104741-6470

1047416470

ISUZU

8943421761

8943421761

Rating:

Cross reference number

ZEXEL

104741-6470

1047416470

ISUZU

8943421761

8943421761

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

67.5

67

68

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

47.5

47.5

47.5

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

61.4

61.4

61.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

67.5

66.5

68.5

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

68

68

68

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1430

1430

1430

Average injection quantity

mm3/st.

14.6

11.6

17.6

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1430

1430

1430

Average injection quantity

mm3/st.

14.6

11.6

17.6

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

8

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

575

575

575

Average injection quantity

mm3/st.

8.4

6.4

10.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment_02

Pump speed

r/min

575

575

575

Average injection quantity

mm3/st.

8.4

6.4

10.4

Difference in delivery

mm3/st.

2

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

80

100

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

80

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

575

575

575

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

50

48

52

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

320

190

450

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

284

264

304

Pressure

kgf/cm2

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

284

264

304

Pressure

kgf/cm2

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

0.6

0.4

0.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

0.6

0.4

0.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1300

1300

1300

Timer stroke

mm

2.5

2.2

2.9

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1.9

1.8

2

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

15

11

19

Control lever angle beta

deg.

30

25

35

Test data Ex:

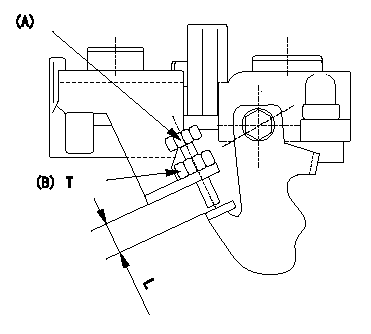

0000001801 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust the adjusting bolt A so that the starting injection quantity adjustment is within the standards.

Fix using nut (B).

----------

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

----------

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

Information:

1. Remove nuts (1), cover (2), and the gasket. 2. Put No. 1 piston at the top center compression position (TC) with the following procedure:a. Remove plug (3), two bolts and cover (2) from the flywheel housing. b. Install Tool (B) in the flywheel housing. Use Tool (B) to slowly rotate the engine in the direction of normal rotation, (counterclockwise as seen from the flywheel end of the engine), until timing bolt (4) can be installed in the flywheel housing and into the hole in the flywheel. c. Remove the valve cover from the valve cover base. Check to see if both rocker arms (5) for the No. 1 cylinder can be moved backward and forward. The No. 1 piston is at the top center compression position (TC) when the timing bolt is installed in the flywheel and both rocker arms for the No. 1 cylinder can be moved backward and forward. If both rocker arms cannot be moved, the No. 1 piston is not at the top center compression position (TC). Remove the timing bolt from the flywheel and rotate the engine in the direction for normal rotation, (counterclockwise as seen from the flywheel end of the engine one full turn 360 degrees, and install the timing bolt again.3. Remove the timing bolt, and use Tool (B) to rotate the engine in the opposite direction of normal rotation (clockwise as seen from the flywheel end of the engine) a minimum of 30 degrees. The timing is correct if Tool (A) and the timing bolt can be installed at the same time. The timing procedure in the Testing & Adjustment Manual must be done again if the timing bolt and Tool (A) can not be installed at the same time.4. Remove the plug from the timing pin hole in the fuel injection pump housing. Install Tool (A) in the timing pin hole. 5. Remove eight bolts (6) and automatic timing advance (7). 6. Remove gear (9) from fuel injection pump camshaft (8).The following steps are for the installation procedure.7. Install gear (9) on fuel injection pump camshaft (8). 8. Install two 3/8 in 16 NC x 6 in (152.4 mm) long guide bolts (10). Space the guide bolts evenly.

There is a light spring located beneath the flyweight cover (12). Hold cover (12) while removing last nut (11). Slowly remove flyweight cover (12) to avoid dropping the spring.

9. Remove four nuts (11) and remove flyweight cover (12). 10. Put automatic timing advance (13) in position on the fuel injection pump camshaft, and install four bolts (14). Tighten bolts (14) just past finger tight. Remove guide bolts (15). 11. Install four nuts (16). Install Tool (C). 12. Tighten four knurled nuts (17) finger tight.

Do not use any tools to tighten the knurled nuts.

13. Install all mounting bolts (14) and tighten to 55 10 N m (41 7 lb ft).14. Loosen knurled nuts (17). Remove four nuts (16) and remove Tool (C).15. Install the spring and flyweight cover

There is a light spring located beneath the flyweight cover (12). Hold cover (12) while removing last nut (11). Slowly remove flyweight cover (12) to avoid dropping the spring.

9. Remove four nuts (11) and remove flyweight cover (12). 10. Put automatic timing advance (13) in position on the fuel injection pump camshaft, and install four bolts (14). Tighten bolts (14) just past finger tight. Remove guide bolts (15). 11. Install four nuts (16). Install Tool (C). 12. Tighten four knurled nuts (17) finger tight.

Do not use any tools to tighten the knurled nuts.

13. Install all mounting bolts (14) and tighten to 55 10 N m (41 7 lb ft).14. Loosen knurled nuts (17). Remove four nuts (16) and remove Tool (C).15. Install the spring and flyweight cover