Information injection-pump assembly

ZEXEL

104741-6180

1047416180

ISUZU

8943389390

8943389390

Rating:

Cross reference number

ZEXEL

104741-6180

1047416180

ISUZU

8943389390

8943389390

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.3

40.8

41.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

34.9

34.9

34.9

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

34.3

34.3

34.3

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.3

40.3

42.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

44.6

44.6

44.6

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

47.1

47.1

47.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

12.9

9.9

15.9

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

12.9

9.9

15.9

Difference in delivery

mm3/st.

4

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

6.7

4.7

8.7

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

6.7

4.7

8.7

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

100

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

60

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Overflow quantity with S/T OFF

cm3/min

530

400

660

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1450

1450

1450

Pressure with S/T OFF

kPa

402

382

422

Pressure with S/T OFF

kgf/cm2

4.1

3.9

4.3

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1900

1900

1900

Pressure with S/T OFF

kPa

569

540

598

Pressure with S/T OFF

kgf/cm2

5.8

5.5

6.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Timer stroke with S/T ON

mm

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1450

1450

1450

Timer stroke with S/T OFF

mm

1

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1900

1900

1900

Timer stroke with S/T OFF

mm

7

6.7

7.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1

0.9

1.1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

31

26

36

Test data Ex:

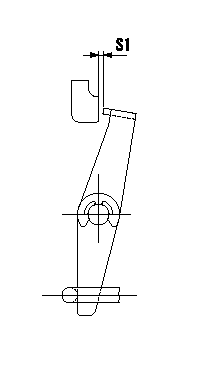

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

Information:

This Program can only be administered after a failure occurs. The decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS5598" as the Part Number and "7755" as the Group Number. Use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

Termination Date

April 30, 2000Problem

A fatigue crack in the nozzle adapter may cause high pressure fuel leaks. Customers will complain of engine misfiring/skipping and fuel leaking from nozzle due to a crack where fuel line is attached.

Affected Product

Model & Identification Number

D250E (5TN975-1839)

D300E (7FN485-1045)

D25D (1HK670-0743)

D30D (3AJ410-0440)

CH65C (2ZJ2400-2537)

970F (7SK800-1113)

615C (2XG1390-1745 9XG850-1210 )

Parts Needed

6 - 0R8782 NOZZLE AS-DIAction Required

If the fuel nozzle adapter cracks on an engine equipped with part number 100-7563 Nozzles in the affected serial number range, replace entire set of 100-7563 Nozzles with 0R8782 Nozzles.

Service Claim Allowances

This is a 2.5-hour job.

Parts Disposition

U.S. and Canadian Dealers

Return all 0R-8782 Nozzles that are replaced to:

Caterpillar Inc.

Service Claims Room

Attention: Howard Jenkel

8201 N. University

Peoria, IL 61615

All other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Termination Date

April 30, 2000Problem

A fatigue crack in the nozzle adapter may cause high pressure fuel leaks. Customers will complain of engine misfiring/skipping and fuel leaking from nozzle due to a crack where fuel line is attached.

Affected Product

Model & Identification Number

D250E (5TN975-1839)

D300E (7FN485-1045)

D25D (1HK670-0743)

D30D (3AJ410-0440)

CH65C (2ZJ2400-2537)

970F (7SK800-1113)

615C (2XG1390-1745 9XG850-1210 )

Parts Needed

6 - 0R8782 NOZZLE AS-DIAction Required

If the fuel nozzle adapter cracks on an engine equipped with part number 100-7563 Nozzles in the affected serial number range, replace entire set of 100-7563 Nozzles with 0R8782 Nozzles.

Service Claim Allowances

This is a 2.5-hour job.

Parts Disposition

U.S. and Canadian Dealers

Return all 0R-8782 Nozzles that are replaced to:

Caterpillar Inc.

Service Claims Room

Attention: Howard Jenkel

8201 N. University

Peoria, IL 61615

All other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.