Information injection-pump assembly

ZEXEL

104741-6160

1047416160

ISUZU

8943389370

8943389370

Rating:

Cross reference number

ZEXEL

104741-6160

1047416160

ISUZU

8943389370

8943389370

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.7

41.2

42.2

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

35.9

35.9

35.9

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

34.5

32

37

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

41.7

40.7

42.7

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

44.6

42.1

47.1

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

46.1

43.1

49.1

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

10.6

8.6

12.6

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

10.6

7.6

13.6

Difference in delivery

mm3/st.

4

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

5.5

3.5

7.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

5.5

3.5

7.5

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

60

60

100

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

60

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Overflow quantity with S/T OFF

cm3/min

540

410

670

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

441

421

461

Pressure with S/T OFF

kgf/cm2

4.5

4.3

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure with S/T OFF

kPa

392

392

392

Pressure with S/T OFF

kgf/cm2

4

4

4

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

441

421

461

Pressure with S/T OFF

kgf/cm2

4.5

4.3

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1800

1800

1800

Pressure with S/T OFF

kPa

539

539

539

Pressure with S/T OFF

kgf/cm2

5.5

5.5

5.5

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

2.2

2

2.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Timer stroke with S/T ON

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1500

1500

1500

Timer stroke with S/T OFF

mm

0.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

2.2

2

2.4

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1800

1800

1800

Timer stroke with S/T OFF

mm

7

6.7

7.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1

0.9

1.1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

31

26

36

Test data Ex:

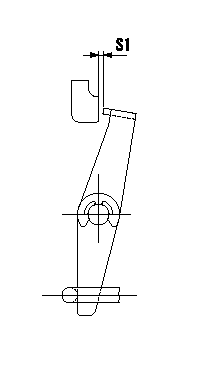

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

Information:

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

Termination Date

August 31, 1997Problem

0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 need to be removed from Parts Stock.Action Required

Inspect all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 from Parts Stock.

The date code can be located below the part name and above the part number on part number tag attached to the box. The date code is formatted as DDMMYYXXX (example; a box marked with a date code of 150195068 would indicate a part manufactured on January 15, 1995 at plant number 068).

If the injector is no longer in the original box, use the date code engraved on the top of the unit injector tappet. It is in the "NUMERAL KOD" format. The code consists of the month and the year.

Where the numbers for the months and years are coded as follows:

January 1997 ... NUDKFebruary 1997... NMDKMarch 1997 ... NEDKApril 1997 ... NRDKTo inspect the injectors, push the rack bar in against the trim adjustment screw (the fuel off position). On the flat "D" section of the rack bar extending out of the injector and beyond the rack teeth, inspect for a shinny grooved machine mark completely across the flat surface and parallel with the rack teeth. This mark is caused by the plunger gear contacting the flat of the rack bar If the mark is present, the injector should be returned to Caterpillar.

Service Claim Allowances

Submit one claim for all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 removed from Parts Stock.

MEPS dealers are reimbursed for recalled Parts Stock by returning the affected Parts Stock to their administering Caterpillar dealer for replacement.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".

Termination Date

August 31, 1997Problem

0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 need to be removed from Parts Stock.Action Required

Inspect all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 from Parts Stock.

The date code can be located below the part name and above the part number on part number tag attached to the box. The date code is formatted as DDMMYYXXX (example; a box marked with a date code of 150195068 would indicate a part manufactured on January 15, 1995 at plant number 068).

If the injector is no longer in the original box, use the date code engraved on the top of the unit injector tappet. It is in the "NUMERAL KOD" format. The code consists of the month and the year.

Where the numbers for the months and years are coded as follows:

January 1997 ... NUDKFebruary 1997... NMDKMarch 1997 ... NEDKApril 1997 ... NRDKTo inspect the injectors, push the rack bar in against the trim adjustment screw (the fuel off position). On the flat "D" section of the rack bar extending out of the injector and beyond the rack teeth, inspect for a shinny grooved machine mark completely across the flat surface and parallel with the rack teeth. This mark is caused by the plunger gear contacting the flat of the rack bar If the mark is present, the injector should be returned to Caterpillar.

Service Claim Allowances

Submit one claim for all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 removed from Parts Stock.

MEPS dealers are reimbursed for recalled Parts Stock by returning the affected Parts Stock to their administering Caterpillar dealer for replacement.

Parts Disposition

All injectors removed from Parts Stock are to be returned as cores for remanufacturing.

U.S. and Canadian Dealers

Return all 0R0906, 0R1756, 0R1758, 0R2921, 0R2922, 0R2923, 0R2924, 0R2925, 0R3051, and 0R3052 Remanufactured Unit Injectors with date codes between January 01, 1997 and April 30, 1997 that are removed from Parts Stock and a copy of the claim to:

Caterpillar Inc.

Attn: Bill Harland - Warranty Review

501 Cardinal Drive

Corinth, MS 38834

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on Remanufactured Engines and Components, refer to the topic "Disposition of the Core Under Warranty".