Information injection-pump assembly

BOSCH

9 460 614 443

9460614443

ZEXEL

104741-5210

1047415210

ISUZU

8970283230

8970283230

Rating:

Cross reference number

BOSCH

9 460 614 443

9460614443

ZEXEL

104741-5210

1047415210

ISUZU

8970283230

8970283230

Zexel num

Bosch num

Firm num

Name

104741-5210

9 460 614 443

8970283230 ISUZU

INJECTION-PUMP ASSEMBLY

4JB1CGT * K

4JB1CGT * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

46.7

45.4

48

Boost pressure

mmHg

350

340

360

Average injection quantity

mm3/st.

49.1

48.6

50.6

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Average injection quantity

mm3/st.

60.9

60.4

61.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

600

600

600

Boost pressure

kPa

13.3

12

14.6

Boost pressure

mmHg

100

90

110

Average injection quantity

mm3/st.

35.8

31.8

39.8

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

24

22.7

25.3

Boost pressure

mmHg

180

170

190

Average injection quantity

mm3/st.

38.2

38.2

38.2

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

46.7

45.4

48

Boost pressure

mmHg

350

340

360

Average injection quantity

mm3/st.

48.2

48.2

48.2

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

46.7

45.4

48

Boost pressure

mmHg

350

340

360

Average injection quantity

mm3/st.

49.1

48.1

50.1

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Average injection quantity

mm3/st.

60.9

59.9

61.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_08

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Average injection quantity

mm3/st.

58.3

54.8

61.8

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Average injection quantity

mm3/st.

16.5

13.5

19.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2600

2600

2600

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Average injection quantity

mm3/st.

16.5

13.5

19.5

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7

5

9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

7

5

9

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

80

60

100

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

80

60

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Pressure with S/T OFF

kPa

314

285

343

Pressure with S/T OFF

kgf/cm2

3.2

2.9

3.5

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Pressure with S/T OFF

kPa

539

510

568

Pressure with S/T OFF

kgf/cm2

5.5

5.2

5.8

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Timer stroke with S/T OFF

mm

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

520

520

520

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Timer stroke with S/T ON

mm

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1050

1050

1050

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Timer stroke with S/T OFF

mm

0.5

0.1

0.9

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Timer stroke with S/T OFF

mm

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1800

1800

1800

Boost pressure

kPa

93.3

92

94.6

Boost pressure

mmHg

700

690

710

Timer stroke with S/T OFF

mm

6.2

5.9

6.6

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

4.8

4.6

5

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

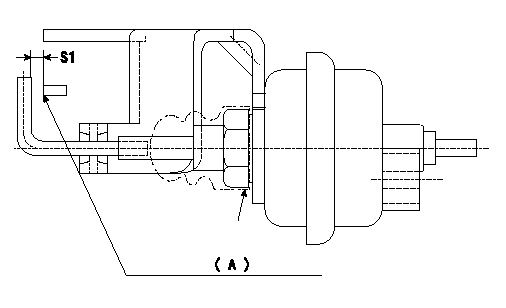

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 kPa {P2 mmHg} to the actuator and confirm that it moves through its full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

Information:

Cut apart used filters to see contaminants. Use a 6V790S FilterCutter

to cut the filter housing.

Maintenance for Engines Using Heavy Fuel

Engines operating on heavy fuel must be carefully monitored and maintained.Service intervals must be strictly observed. Operators must be trained toperform a thorough service inspection.

"As Needed" Periodic Activities

Test fuel as it is delivered. Identify contaminant levels immediately and notify appropriate operations personnel.

Before storage, test for compatibility between fuel in the tanks and the fuel being purchased. Keep the fuel in separate tanks if possible.

Use regular S.O.S oil analysis to determine if there are wear particles in the oil, and maintain the proper TBN level.

Request infrared analysis on used oils to determine the effects of burning heavy fuel on the crankcase oil.

Daily Activities

Maintain and monitor fuel treatment equipment.

Record engine temperatures to assure adequate jacket water temperature, aftercooler temperature, and air intake temperature.

If equipped with a turbocharger water wash attachment, wash the turbocharger exhaust turbine. It is necessary to remove deposits from the turbine side of the turbocharger. (A washer attachment which does this is available on 3600 Family Engines.)

Check exhaust thermocouples and record exhaust temperatures. Be alert for worn exhaust valves.

Measure valve stem projection when new; use a stationary point such asthe valve cover gasket surface for a reference point. Record the measurementsfor each valve for later follow-up measurements. If valve stem projection movesmore than 1.25 mm (.050 in.) consider disassembly to find the reason. Anotherway to observe valve face wear is to measure and record changes on valve lashover a period of time.

Monitor fuel and oil filter differentials every shift. Check for filter plugging.

Drain settling and fuel tank bottoms daily. Take note if there is excessive water or sediment.

Every 1000 Hours

Check one cylinder head for exhaust valve seating and carbon build-up. Check the fuel injectors for adequate nozzle spray pattern. Make sure the valve rotators are operating.

Clean the turbocharger (exhaust turbine) (3500 and 3600 Family Engines without washers).

Operating the Engine at Low Load

If you're expecting to operate your engine at part load for extendedperiods, switch to No.2 diesel fuel or marine diesel oil. (Make sure the fuelinjectors are not run without fuel during the switch.)

The following chart shows the relationship between engine load and length oftime. It will guide you on what type of fuel to burn in light load applications.

Chart with time and numbers.

Other Heavy Fuel Tips

Here are some things to keep in mind when using heavy fuels.

Cut apart used filters to see contaminants. As contamination levels increase, the quality of diesel fuel is generally decreasing.

As fuel quality decreases, it becomes even more important to have good fuel treatment systems. The treatment system can sometimes compensate for poor fuel quality. ..but there is less margin for error with a system that is not working correctly.

Often, diesel engines cannot operate on fuel that is straight from the fuel tank (bunkered).

Viscosity does not relate to quality. Do not use fuel thickness

Have questions with 104741-5210?

Group cross 104741-5210 ZEXEL

Isuzu

104741-5210

9 460 614 443

8970283230

INJECTION-PUMP ASSEMBLY

4JB1CGT

4JB1CGT