Information injection-pump assembly

BOSCH

F 01G 09W 0AS

f01g09w0as

ZEXEL

104741-4960

1047414960

NISSAN-DIESEL

16700NA01B

16700na01b

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Injection VE Pump VE4/11F1000RNP2611 Compatible For NISSAN QD32 Diesel Fuel Pump 104641-4960 16700-NA01B 16700NA01B

BSZBAS OEM:VE4/11F1000RNP2611 104641-4960 16700-NA01B 16700NA01B || Timely replacement of accessories can extend the service life of equipment || Improving overall efficiency after replacing parts || Please check the product pictures, accessories, and part numbers or OEM numbers before placing an order || If you are unsure, please feel free to ask us before making a purchase

BSZBAS OEM:VE4/11F1000RNP2611 104641-4960 16700-NA01B 16700NA01B || Timely replacement of accessories can extend the service life of equipment || Improving overall efficiency after replacing parts || Please check the product pictures, accessories, and part numbers or OEM numbers before placing an order || If you are unsure, please feel free to ask us before making a purchase

Injection VE Pump VE4/11F1000RNP2611 Compatible For NISSAN QD32 Diesel Fuel Pump 104641-4960 16700-NA01B 16700NA01B

BSZBAS OEM:VE4/11F1000RNP2611 104641-4960 16700-NA01B 16700NA01B || Shell impact resistance || Dual filtration system effectively intercepts impurities and reduces blockage issues || Wide compatibility, meets OEM specifications, allows for direct replacement of parts without the need for modification || After replacement, the throttle response significantly increased and fuel consumption decreased

BSZBAS OEM:VE4/11F1000RNP2611 104641-4960 16700-NA01B 16700NA01B || Shell impact resistance || Dual filtration system effectively intercepts impurities and reduces blockage issues || Wide compatibility, meets OEM specifications, allows for direct replacement of parts without the need for modification || After replacement, the throttle response significantly increased and fuel consumption decreased

104641-4961 16700-NA01B Engine Parts Diesel Fuel Injection Pump,compatible For Engine Excavator

NZMSMS Precision - Engineered Compatibility: The 104641-4961 16700-NA01B Engine Parts Diesel Fuel Injection Pump is meticulously designed to offer a seamless fit for a wide range of excavator engines. Our engineers have thoroughly studied the unique fuel system requirements of various excavator models, ensuring that every dimension, connection interface, and internal component aligns perfectly with the original equipment. Whether you’re a professional mechanic maintaining a fleet of excavators or an || Enhanced Performance for Demanding Jobs: Engineered with cutting - edge technology, this fuel injection pump is built to boost the performance of your excavator engine. Advanced sensors continuously monitor critical engine parameters such as speed, load, and temperature during heavy - duty operations. Paired with intelligent control systems, it makes instant and accurate adjustments to the fuel injection volume and timing. As a result, your excavator engine receives the precise amount of fuel || Rugged and Durable Construction: Excavators operate in some of the harshest environments, and our 104641-4961 16700-NA01B fuel injection pump is built to withstand it all. Constructed from high - quality, heavy - duty materials, the pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to dust, moisture, vibrations, and extreme temperatures. The internal components, including injection nozzles, plungers, and valves, are crafted from premium - grade materials || Fuel - Saving Efficiency: In an industry where fuel costs can significantly impact your bottom line, our fuel injection pump offers an effective solution to optimize fuel consumption for excavator engines. By delivering a precise and consistent fuel supply, it enables the engine to achieve a more efficient fuel - air combustion. The intelligent control system prevents over - injection, ensuring that every drop of fuel is utilized effectively. In a 15,000 - hour field test across multiple || Reliable Operation in All Conditions: No matter the job site environment or operating conditions, this fuel injection pump performs consistently for excavator engines. Engineered to function reliably in extreme cold, sweltering heat, and dusty or wet environments, it features intelligent pressure regulation and monitoring systems that maintain optimal fuel injection pressure within a tight tolerance of ± 0.2 psi. It can also handle variations in fuel quality, ensuring smooth operation even when

NZMSMS Precision - Engineered Compatibility: The 104641-4961 16700-NA01B Engine Parts Diesel Fuel Injection Pump is meticulously designed to offer a seamless fit for a wide range of excavator engines. Our engineers have thoroughly studied the unique fuel system requirements of various excavator models, ensuring that every dimension, connection interface, and internal component aligns perfectly with the original equipment. Whether you’re a professional mechanic maintaining a fleet of excavators or an || Enhanced Performance for Demanding Jobs: Engineered with cutting - edge technology, this fuel injection pump is built to boost the performance of your excavator engine. Advanced sensors continuously monitor critical engine parameters such as speed, load, and temperature during heavy - duty operations. Paired with intelligent control systems, it makes instant and accurate adjustments to the fuel injection volume and timing. As a result, your excavator engine receives the precise amount of fuel || Rugged and Durable Construction: Excavators operate in some of the harshest environments, and our 104641-4961 16700-NA01B fuel injection pump is built to withstand it all. Constructed from high - quality, heavy - duty materials, the pump housing is made from a robust, corrosion - resistant alloy that can endure exposure to dust, moisture, vibrations, and extreme temperatures. The internal components, including injection nozzles, plungers, and valves, are crafted from premium - grade materials || Fuel - Saving Efficiency: In an industry where fuel costs can significantly impact your bottom line, our fuel injection pump offers an effective solution to optimize fuel consumption for excavator engines. By delivering a precise and consistent fuel supply, it enables the engine to achieve a more efficient fuel - air combustion. The intelligent control system prevents over - injection, ensuring that every drop of fuel is utilized effectively. In a 15,000 - hour field test across multiple || Reliable Operation in All Conditions: No matter the job site environment or operating conditions, this fuel injection pump performs consistently for excavator engines. Engineered to function reliably in extreme cold, sweltering heat, and dusty or wet environments, it features intelligent pressure regulation and monitoring systems that maintain optimal fuel injection pressure within a tight tolerance of ± 0.2 psi. It can also handle variations in fuel quality, ensuring smooth operation even when

You can express buy:

USD 388.94

14-06-2025

14-06-2025

Brand New Injection VE Pump VE4/11F1000RNP2611 for NISSAN QD32 Diesel Fuel Pump 104641-4960 16700-NA01B 16700NA01B

USD 433.07

14-06-2025

14-06-2025

Brand New Injection VE Pump VE4/11F1000RNP2611 for NISSAN QD32 Diesel Fuel Pump 104641-4960 16700-NA01B 16700NA01B

Images:

USD 406.7

[19-May-2025]

USD 437.32

[14-Jun-2025]

USD 426.92

[19-May-2025]

USD 411.32

[13-May-2025]

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-4960 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1221 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8(100) |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2320 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-4520 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-5420 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-5200 | COMPRESSION SPRING |

| 34B. | [1] | 146312-6000 | COMPRESSION SPRING |

| 34C. | [1] | 146312-6800 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM |

| 35/1. | [1] | 146690-3300 | SHIM |

| 35/1. | [1] | 146690-3400 | SHIM |

| 35/1. | [1] | 146690-3500 | SHIM |

| 35/1. | [1] | 146690-4100 | SHIM |

| 35/1. | [1] | 146690-4200 | SHIM |

| 35/1. | [1] | 146690-4300 | SHIM |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-5100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-5300 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0100 | SHIM |

| 48/1. | [1] | 146603-0200 | SHIM |

| 48/1. | [1] | 146603-0300 | SHIM |

| 48/1. | [1] | 146603-0400 | SHIM |

| 48/1. | [1] | 146690-1400 | SHIM |

| 48/1. | [1] | 146690-1500 | SHIM |

| 48/1. | [1] | 146690-1600 | SHIM |

| 48/1. | [1] | 146690-1700 | SHIM |

| 48/1. | [1] | 146690-1800 | SHIM |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0700 | SHIM |

| 52/1. | [1] | 146420-0800 | SHIM |

| 52/1. | [1] | 146420-0900 | SHIM |

| 52/1. | [1] | 146420-1000 | SHIM |

| 52/1. | [1] | 146420-1100 | SHIM |

| 52/1. | [1] | 146420-1200 | SHIM |

| 52/1. | [1] | 146420-1300 | SHIM |

| 52/1. | [1] | 146420-1400 | SHIM |

| 52/1. | [1] | 146420-1500 | SHIM |

| 52/1. | [1] | 146420-1600 | SHIM |

| 52/1. | [1] | 146420-1700 | SHIM |

| 52/1. | [1] | 146420-1800 | SHIM |

| 52/1. | [1] | 146420-1900 | SHIM |

| 52/1. | [1] | 146420-2000 | SHIM |

| 52/1. | [1] | 146420-2100 | SHIM |

| 52/1. | [1] | 146420-2200 | SHIM |

| 52/1. | [1] | 146420-2400 | SHIM |

| 52/1. | [1] | 146420-2500 | SHIM |

| 52/1. | [1] | 146420-2600 | SHIM |

| 52/1. | [1] | 146420-2700 | SHIM |

| 52/1. | [1] | 146420-2800 | SHIM |

| 52/1. | [1] | 146420-2900 | SHIM |

| 52/1. | [1] | 146420-3000 | SHIM |

| 52/1. | [1] | 146420-3100 | SHIM |

| 52/1. | [1] | 146420-3200 | SHIM |

| 52/1. | [1] | 146420-3300 | SHIM |

| 52/1. | [1] | 146420-3400 | SHIM |

| 52/1. | [1] | 146420-3500 | SHIM |

| 52/1. | [1] | 146420-3600 | SHIM |

| 52/1. | [1] | 146420-3700 | SHIM |

| 52/1. | [1] | 146420-3800 | SHIM |

| 52/1. | [1] | 146420-3900 | SHIM |

| 52/1. | [1] | 146420-4000 | SHIM |

| 52/1. | [1] | 146420-4100 | SHIM |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0200 | COMPRESSION SPRING |

| 58. | [4] | 146440-0720 | FITTING |

| 60. | [4] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146822-0220 | GOVERNOR COVER |

| 67/1. | [1] | 146805-2120 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/4. | [2] | 139310-0200 | PLAIN WASHER |

| 67/5. | [1] | 146530-0000 | CONTROL LEVER |

| 67/5B. | [1] | 146530-0100 | CONTROL LEVER |

| 67/5C. | [1] | 146832-1500 | CONTROL LEVER |

| 67/5D. | [1] | 146832-1600 | CONTROL LEVER |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER |

| 67/6. | [2] | 014110-6440 | LOCKING WASHER |

| 67/7. | [1] | 013020-6040 | UNION NUT |

| 67/8. | [1] | 146515-1820 | LEVER SHAFT |

| 67/9. | [1] | 146592-0400 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER |

| 67/12. | [1] | 146540-4000 | CONTROL LEVER |

| 67/12B. | [1] | 146540-4100 | CONTROL LEVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/16. | [1] | 146526-6400 | BLEEDER SCREW |

| 67/18. | [1] | 146594-0600 | COILED SPRING |

| 67/19. | [1] | 146541-0000 | ANGLE PIECE |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/25. | [2] | 013020-6040 | UNION NUT |

| 67/26. | [1] | 139006-0200 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/104. | [1] | 146936-1100 | BRACKET |

| 67/105. | [1] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN |

| 67/201B. | [1] | 146545-3500 | THREADED PIN |

| 67/201C. | [1] | 146545-3600 | THREADED PIN |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 95. | [1] | 146891-1820 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM |

| 110/1. | [1] | 146571-0100 | SHIM |

| 110/1. | [1] | 146571-0200 | SHIM |

| 110/1. | [1] | 146571-0300 | SHIM |

| 110/1. | [1] | 146571-0400 | SHIM |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-2600 | PLAIN WASHER |

| 115. | [1] | 146976-2900 | SLIDING SLEEVE |

| 116. | [1] | 146576-0400 | CAP |

| 117/1. | [1] | 146877-1020 | PLUG |

| 117/1. | [1] | 146877-1120 | PLUG |

| 117/1. | [1] | 146877-1220 | PLUG |

| 117/1. | [1] | 146877-1320 | PLUG |

| 117/1. | [1] | 146877-1420 | PLUG |

| 117/1. | [1] | 146877-1520 | PLUG |

| 117/1. | [1] | 146877-1620 | PLUG |

| 117/1. | [1] | 146877-1720 | PLUG |

| 117/1. | [1] | 146877-1820 | PLUG |

| 117/1. | [1] | 146877-1920 | PLUG |

| 117/1. | [1] | 146877-2020 | PLUG |

| 117/1. | [1] | 146877-2120 | PLUG |

| 117/1. | [1] | 146877-2220 | PLUG |

| 117/1. | [1] | 146877-2320 | PLUG |

| 117/1. | [1] | 146877-2420 | PLUG |

| 117/1. | [1] | 146877-2520 | PLUG |

| 117/1. | [1] | 146877-2620 | PLUG |

| 120. | [1] | 146579-2720 | RETAINING PIN |

| 122. | [1] | 146580-4100 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0520 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0120 | OVER FLOW VALVE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-8320 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 351. | [1] | 146125-0101 | FILTER |

| 352. | [1] | 146125-0200 | COILED SPRING |

| 800S. | [1] | 146019-8820 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-1520 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0320 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP |

| 836S/1. | [1] | 146598-0700 | CAP |

| 836S/1. | [1] | 146598-0800 | CAP |

| 836S/1. | [1] | 146598-0900 | CAP |

| 906. | [1] | 146984-8000 | NAMEPLATE |

| 907. | [1] | 025803-1640 | WOODRUFF KEY |

Include in #2:

104741-4960

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 01G 09W 0AS

f01g09w0as

ZEXEL

104741-4960

1047414960

NISSAN-DIESEL

16700NA01B

16700na01b

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

54

53.5

54.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

50

50

50

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

50.6

46.6

54.6

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

52.1

52.1

52.1

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

54

53

55

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

52.9

49.4

56.4

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

1245

1245

1245

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

50

48

52

Injection quantity adjustment_02

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment_03

Pump speed

r/min

1245

1245

1245

Average injection quantity

mm3/st.

8

4.5

11.5

Basic

*

Oil temperature

degC

50

48

52

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

8

5.5

10.5

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

56.9

51.9

61.9

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

56.9

51.9

61.9

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

900

900

900

Overflow quantity

cm3/min

440

310

570

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

900

900

900

Pressure

kPa

549

520

578

Pressure

kgf/cm2

5.6

5.3

5.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

900

900

900

Pressure

kPa

549

510

588

Pressure

kgf/cm2

5.6

5.2

6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

588

549

627

Pressure

kgf/cm2

6

5.6

6.4

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

900

900

900

Timer stroke

mm

2.3

2.1

2.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

800

800

800

Timer stroke

mm

1.8

1.3

2.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

900

900

900

Timer stroke

mm

2.3

2

2.6

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

2.9

2.4

3.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

32

31.5

32.5

Timer stroke TA

mm

1.6

1.4

1.8

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

32

31

33

Timer stroke TA

mm

1.6

1.3

1.9

Timer stroke variation dT

mm

0.7

0.7

0.7

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

18

15.5

20.5

Timer stroke TA

mm

0.9

0.4

1.4

Timer stroke variation dT

mm

1.4

1.4

1.4

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.62

5.52

5.72

MS dimension

mm

1.8

1.7

1.9

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

28

23

33

Test data Ex:

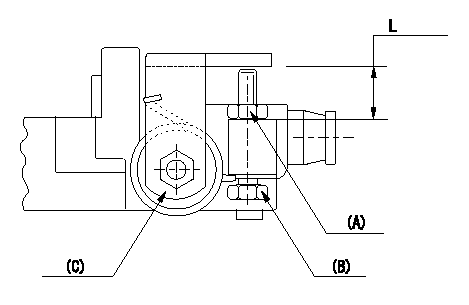

0000001801 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

Information:

Refer to attached Rework Procedure.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-2000 hrs,

0-12 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

2001-5000 hrs,

13-18 mo 100.0% 50.0% 0.0% 0.0% 0.0% 50.0%

5001-8000 hrs,

19-24 mo 100.0% 30.0% 0.0% 0.0% 0.0% 70.0%

This is a 4.0-hour job for Group 1

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-2000 hrs,

0-12 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

2001-5000 hrs,

13-18 mo 100.0% 50.0% 0.0% 0.0% 0.0% 50.0%

5001-8000 hrs,

19-24 mo 100.0% 30.0% 0.0% 0.0% 0.0% 70.0%

This is a 4.0-hour job for Group 2

PARTS DISPOSITION

removed java code "affectDisposition"commented on Chints October 12 2006 Chints w.r.t CM000343756-->

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

For the following units listed remove (6) 207-5248 Injector Rocker Arms, and replace with (6) 278-1365 Injector Rocker Arms.

For proper ?Disassembly & Assembly? instructions of the injector rocker arms please refer to the following Publications in SIS Web. (SENR9832-06 Testing & Adjusting-Finding Top Dead Center Position for No. 1 Piston), (SENR9832-06 Testing & Adjusting-Electronic Unit Injector Adjusting & Setting), and (SENR9832-06 Testing & Adjusting-Engine Valve Lash Inspect/Adjust).

Note: It is important that while installing the 278-1365 Injector Rocker Arms, that the engine is in the proper position (Top Dead Center and 180 degrees out) so the Injector Rocker Arms are properly adjusted and set. It is also important that during the installation of the Injector Rocker Arms that the Exhaust Valve, and Intake Valve lash settings be inspected and if needed re-set to factory specifications.

Note: During the rework process please inspect the 6I-0901 Rocker Arm Shafts for any signs of misalignment of the stud mounting holes, wear, damage, fretting etc. If damage is found to the shaft or if fretting or damage is found with any of the through bolt/stud mounting holes, the shaft is to be replaced, and reported against this service letter as contingent damage.