Information injection-pump assembly

BOSCH

9 460 614 010

9460614010

ZEXEL

104741-4750

1047414750

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-4750 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104641-4750 |

| 3. | NUMBER PLATE | 146983-4600 |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1221 |

| 8. | Nozzle and Holder | 16600-63G01 |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8{100} |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2320 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-4520 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6320 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2600 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2700 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2500 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-5100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-5300 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0200 | COMPRESSION SPRING |

| 58. | [4] | 146440-0720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-9520 | GOVERNOR COVER |

| 67/1. | [1] | 146508-4821 | GOVERNOR COVER |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/6. | [1] | 014110-6440 | LOCKING WASHER |

| 67/8. | [1] | 146515-1820 | LEVER SHAFT |

| 67/9. | [1] | 146592-0400 | COILED SPRING |

| 67/10. | [1] | 146600-0200 | O-RING |

| 67/11. | [1] | 146602-0100 | PLAIN WASHER D14&10.1T1.50 |

| 67/12. | [1] | 146540-4000 | CONTROL LEVER |

| 67/12B. | [1] | 146540-4100 | CONTROL LEVER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/25. | [2] | 013020-6040 | UNION NUT M6P1H5 |

| 67/25. | [2] | 013020-6040 | UNION NUT M6P1H5 |

| 67/26. | [1] | 139006-0200 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146811-0120 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146832-6320 | CONTROL LEVER |

| 72B. | [1] | 146832-6420 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 146621-0700 | UNION NUT |

| 95. | [1] | 146871-6220 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-7500 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [3] | 139106-0200 | FLAT-HEAD SCREW |

| 124. | [1] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0920 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-3100 | SLOTTED WASHER |

| 218. | [1] | 146587-9900 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146587-8000 | COILED SPRING |

| 221. | [1] | 146925-2622 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 230. | [1] | 146935-9820 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-0720 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 242. | [1] | 146662-6520 | WIRE |

| 243. | [1] | 146621-4901 | UNION NUT |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 309. | [6] | 139006-4400 | BLEEDER SCREW |

| 309. | [6] | 139006-4400 | BLEEDER SCREW |

| 309. | [6] | 139006-4400 | BLEEDER SCREW |

| 310. | [1] | 146685-6520 | POTENTCIOMETER |

| 310/2. | [1] | 146936-0720 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146620-2900 | FLAT-HEAD SCREW |

| 310/5. | [1] | 146621-0500 | UNION NUT |

| 310/6. | [1] | 146614-2300 | JOINT CONNECTION |

| 310/7. | [1] | 146661-0401 | BOOT |

| 311. | [2] | 146622-0600 | BLEEDER SCREW |

| 316. | [1] | 146680-4520 | DAMPER |

| 317. | [1] | 139006-6600 | BLEEDER SCREW |

| 318. | [1] | 146936-0000 | BRACKET |

| 319. | [1] | 146936-0500 | BRACKET |

| 321. | [1] | 146936-0600 | PLATE |

| 326. | [1] | 146620-7300 | BLEEDER SCREW |

| 351. | [1] | 146125-0101 | FILTER |

| 352. | [1] | 146125-0200 | COILED SPRING |

| 800S. | [1] | 146019-9920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-1520 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146685-0410 | POTENTCIOMETER |

| 906. | [1] | 146983-4600 | NAMEPLATE |

Include in #2:

104741-4750

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 614 010

9460614010

ZEXEL

104741-4750

1047414750

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

44.8

44.3

45.3

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

46.7

43.2

50.2

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

46.2

42.7

49.7

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

44.8

43.8

45.8

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

45.1

41.6

48.6

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

44.5

41

48

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

17.7

15.7

19.7

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

17.7

15.2

20.2

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

6.3

10.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

5.8

10.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Boost compensator adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

19.4

9.4

29.4

Oil temperature

degC

50

48

52

Lever angle (shim thickness)

mm

14

13.95

14.05

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

65

75

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

65

75

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

390

260

520

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

539

519

559

Pressure

kgf/cm2

5.5

5.3

5.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

539

500

578

Pressure

kgf/cm2

5.5

5.1

5.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

736

677

795

Pressure

kgf/cm2

7.5

6.9

8.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.9

3.7

4.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

600

600

600

Timer stroke

mm

1.3

0.7

1.9

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.9

3.6

4.2

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

7.8

7.3

8.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2050

2050

2050

Timer stroke

mm

7.8

7.3

8.2

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

30

29.5

30.5

Timer stroke TA

mm

3.3

3.1

3.5

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

30

29

31

Timer stroke TA

mm

3.3

3

3.6

Timer stroke variation dT

mm

0.6

0.6

0.6

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

18

15.5

20.5

Timer stroke TA

mm

2.4

1.9

2.9

Timer stroke variation dT

mm

1.5

1.5

1.5

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.62

5.52

5.72

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

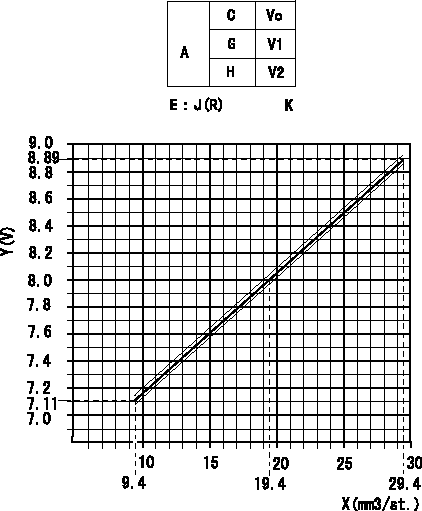

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

In the following condition, change the installation position of the potentiometer to adjust the output voltage to within the specified values.

Measure the injection quantity at control lever position a (shim thickness = approximately L mm) at N = N1 r/min, determine the voltage using the formula, and adjust the potentiometer.

A:Performance standards

C:Position of the control lever

N:Pump speed

Vo:Output voltage

E:Conversion formula

G:Idling

H:Full speed

K:Applied voltage

X:Injection quantity (cm3/1,000st)

Y:Voltage (V)

M:Connecting diagram for the potentiometer

O:Output

P:Output when (2) and (3) connected.

R:At target value Q1cm3/1,000 st, set voltage at V3 (V).

----------

N1=1500r/min a=22.9deg L=14.0+-0.05mm Q1=19.4cm3/1000st V3=7.72V

----------

V1=1.19+-0.9V V2=9.0++V K=10V J=V+-0.03=0.0886X+6.001

----------

N1=1500r/min a=22.9deg L=14.0+-0.05mm Q1=19.4cm3/1000st V3=7.72V

----------

V1=1.19+-0.9V V2=9.0++V K=10V J=V+-0.03=0.0886X+6.001

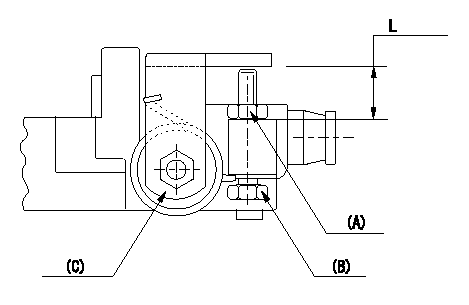

0000001901 STOP LEVER ADJUSTMENT

Adjustment of the stop lever

Adjust adjusting bolt (B) so that the starting injection quantity is within the standard.

Fix using nut.

(A) Adjusting nut

(C) Starting injection quantity adjusting lever

----------

----------

L=15.0~18.5mm

----------

----------

L=15.0~18.5mm

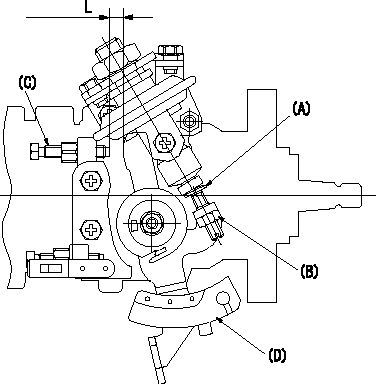

0000002001 DASHPOT ADJUSTMENT

Dashpot installation standard

Insert block gauge L between idle set screw C and control lever D (so that control lever position is a). Then, in this control lever position, adjust dashpot adjusting screw A so that it contacts the pushrod, and fix using lock nut B.

Nut tightening torque is T.

Also confirm that the dashpot - adjusting screw faces are smooth and that the control lever returns to the idle position.

----------

L=7.5+-0.05mm a=11.6deg T=4.9~7N-m(0.50~0.7kgf-m)

----------

L=7.5+-0.05mm

----------

L=7.5+-0.05mm a=11.6deg T=4.9~7N-m(0.50~0.7kgf-m)

----------

L=7.5+-0.05mm

Information:

Starting System

Use a D.C. voltmeter to locate starting system components which do not function.Move starting control switch to energize the starter solenoid. Starter solenoid operation is audible as the starter motor pinion engages with the ring gear on the engine flywheel. The solenoid operation should also close the electric circuit to the motor. Attach one voltmeter lead to the solenoid terminal that is connected to the motor. Ground the other lead. Energize the starter solenoid and observe the voltmeter. A battery voltage reading indicates the malfunction is in the motor. It must be removed for further testing. No voltmeter reading indicates that the solenoid contacts do not close and the solenoid must be repaired or the starter pinion clearance should be adjusted.A starting motor solenoid that will not operate may not be receiving battery current. Attach one lead of the voltmeter to the solenoid battery cable connection. Ground the other lead. No voltmeter reading indicates a faulty circuit from the battery. A voltmeter reading indicates further testing is necessary.Continue the test by attaching one voltmeter lead to the starting motor solenoid small wire terminal and the other lead to ground. Observe the voltmeter and energize the starter solenoid. A voltmeter reading indicates that the malfunction is in the solenoid. No voltmeter reading indicates the starter switch or wiring is the fault.Attach one lead of the voltmeter to the starter switch battery wire terminal and ground the other lead. A voltmeter reading indicates a defective switch.A starting motor that operates too slow can be overloaded by excessive mechanical friction within the engine being started. Slow starting motor operation can also be caused by shorts, loose connections and/or excessive dirt within the motor.Pinion Clearance Adjustment (Prestolite)

There are two adjustments on this type motor. Armature end play and pinion position.Armature End Play

Adjust the end play to .005 to .030 in. (0.13 to 0.76 mm) by adding or removing thrust washers on the commutator end of the armature shaft.Pinion Position

This adjustment is accomplished in two steps.1. To adjust the pinion distance, connect the solenoid to a 12 volt battery as shown.Momentarily flash the jumper lead from the motor terminal stud of the solenoid to the terminal stud at (1) in the commutator end head to shift the solenoid and drive into the cranking position.

CONNECTIONS FOR ADJUSTING THE PINION POSITION

1. Jumper lead flashing point.Remove the jumper lead. The drive will remain in the cranking position until the battery is disconnected.Push the drive toward the commutator end of the motor to eliminate any slack movement in the linkage and measure the distance between the outside edge of the drive sleeve and the thrust washer. The distance (3) must be .02 to .05 in. (0.5 to 1.3 mm).Adjust to this dimension by turning the adjusting nut (2) in or out as required.

PINION POSITION ADJUSTMENT

2. Adjusting nut. 3. Distance.2. To test assembly of solenoid, it will be necessary to have an interference block cut to the dimensions shown.

INTERFERENCE BLOCK DIMENSIONSConnect the solenoid to 24 volts as

Use a D.C. voltmeter to locate starting system components which do not function.Move starting control switch to energize the starter solenoid. Starter solenoid operation is audible as the starter motor pinion engages with the ring gear on the engine flywheel. The solenoid operation should also close the electric circuit to the motor. Attach one voltmeter lead to the solenoid terminal that is connected to the motor. Ground the other lead. Energize the starter solenoid and observe the voltmeter. A battery voltage reading indicates the malfunction is in the motor. It must be removed for further testing. No voltmeter reading indicates that the solenoid contacts do not close and the solenoid must be repaired or the starter pinion clearance should be adjusted.A starting motor solenoid that will not operate may not be receiving battery current. Attach one lead of the voltmeter to the solenoid battery cable connection. Ground the other lead. No voltmeter reading indicates a faulty circuit from the battery. A voltmeter reading indicates further testing is necessary.Continue the test by attaching one voltmeter lead to the starting motor solenoid small wire terminal and the other lead to ground. Observe the voltmeter and energize the starter solenoid. A voltmeter reading indicates that the malfunction is in the solenoid. No voltmeter reading indicates the starter switch or wiring is the fault.Attach one lead of the voltmeter to the starter switch battery wire terminal and ground the other lead. A voltmeter reading indicates a defective switch.A starting motor that operates too slow can be overloaded by excessive mechanical friction within the engine being started. Slow starting motor operation can also be caused by shorts, loose connections and/or excessive dirt within the motor.Pinion Clearance Adjustment (Prestolite)

There are two adjustments on this type motor. Armature end play and pinion position.Armature End Play

Adjust the end play to .005 to .030 in. (0.13 to 0.76 mm) by adding or removing thrust washers on the commutator end of the armature shaft.Pinion Position

This adjustment is accomplished in two steps.1. To adjust the pinion distance, connect the solenoid to a 12 volt battery as shown.Momentarily flash the jumper lead from the motor terminal stud of the solenoid to the terminal stud at (1) in the commutator end head to shift the solenoid and drive into the cranking position.

CONNECTIONS FOR ADJUSTING THE PINION POSITION

1. Jumper lead flashing point.Remove the jumper lead. The drive will remain in the cranking position until the battery is disconnected.Push the drive toward the commutator end of the motor to eliminate any slack movement in the linkage and measure the distance between the outside edge of the drive sleeve and the thrust washer. The distance (3) must be .02 to .05 in. (0.5 to 1.3 mm).Adjust to this dimension by turning the adjusting nut (2) in or out as required.

PINION POSITION ADJUSTMENT

2. Adjusting nut. 3. Distance.2. To test assembly of solenoid, it will be necessary to have an interference block cut to the dimensions shown.

INTERFERENCE BLOCK DIMENSIONSConnect the solenoid to 24 volts as