Information injection-pump assembly

BOSCH

9 460 614 435

9460614435

ZEXEL

104741-4720

1047414720

NISSAN-DIESEL

1670058N16

1670058n16

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-4720 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1221 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8(100) |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1210 |

Scheme ###:

| 1/6. | [1] | 146601-0900 | PACKING RING |

| 6. | [1] | 146100-0420 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0020 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0000 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-2320 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-4520 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-6420 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-2900 | COMPRESSION SPRING |

| 34B. | [1] | 146312-3000 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2800 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-5100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-5300 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 50. | [1] | 146401-4220 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY VE4 |

| 56. | [4] | 146432-0200 | COMPRESSION SPRING |

| 58. | [4] | 146440-0720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146503-2220 | GOVERNOR COVER |

| 67/1. | [1] | 146508-2221 | GOVERNOR COVER |

| 67/13. | [1] | 146621-3100 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-6400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146810-5020 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146537-7720 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 146621-0700 | UNION NUT |

| 79. | [1] | 146926-2320 | PLATE |

| 95. | [1] | 146861-8620 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146975-5600 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0920 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 217. | [1] | 146541-3100 | SLOTTED WASHER |

| 218. | [1] | 146587-9900 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146587-8000 | COILED SPRING |

| 221. | [1] | 146926-9100 | BRACKET |

| 222. | [2] | 139006-4600 | BLEEDER SCREW |

| 223. | [1] | 146671-2220 | SWITCH |

| 227. | [2] | 020105-0940 | BLEEDER SCREW |

| 230. | [1] | 146935-1621 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 236. | [1] | 139006-4800 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-4901 | UNION NUT |

| 246. | [1] | 027412-2440 | EYE BOLT |

| 309. | [1] | 139006-5700 | BLEEDER SCREW |

| 310. | [1] | 146685-1920 | POTENTCIOMETER |

| 310/2. | [1] | 146934-5621 | BRACKET |

| 310/3. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/4. | [1] | 146620-2900 | FLAT-HEAD SCREW |

| 310/5. | [1] | 146621-0500 | UNION NUT |

| 310/6. | [1] | 146614-2300 | JOINT CONNECTION |

| 311. | [2] | 010206-1040 | HEX-SOCKET-HEAD CAP SCREW |

| 312. | [1] | 146659-1600 | CLAMPING BAND |

| 313. | [1] | 139006-4600 | BLEEDER SCREW |

| 329. | [1] | 146541-4900 | PLAIN WASHER |

| 351. | [1] | 146125-0101 | FILTER |

| 352. | [1] | 146125-0200 | COILED SPRING |

| 800S. | [1] | 146019-9920 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0900 | PACKING RING |

| 804S. | [1] | 146232-1520 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 847S. | [1] | 146684-9310 | POTENTCIOMETER |

| 906. | [1] | 146983-2500 | NAMEPLATE |

| 907. | [1] | 025803-1640 | WOODRUFF KEY |

Include in #2:

104741-4720

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 614 435

9460614435

ZEXEL

104741-4720

1047414720

NISSAN-DIESEL

1670058N16

1670058n16

Zexel num

Bosch num

Firm num

Name

104741-4720

9 460 614 435

1670058N16 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

QD32 K

QD32 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

58.3

57.8

58.8

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

52.4

48.9

55.9

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

54.7

51.2

58.2

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

58.3

57.3

59.3

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

54.9

51.9

57.9

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

55

52

58

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

18.6

16.6

20.6

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2600

2600

2600

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

18.6

16.1

21.1

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

15

13

17

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

15

12.5

17.5

Difference in delivery

mm3/st.

3

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

75

110

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

75

110

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

390

260

520

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

539

519

559

Pressure

kgf/cm2

5.5

5.3

5.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

539

500

578

Pressure

kgf/cm2

5.5

5.1

5.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1800

1800

1800

Pressure

kPa

736

677

795

Pressure

kgf/cm2

7.5

6.9

8.1

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.6

3.4

3.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

600

600

600

Timer stroke

mm

1.5

1

2

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

3.6

3.3

3.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

7.5

7

8

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2100

2100

2100

Timer stroke

mm

8.2

7.6

8.7

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

40.5

40

41

Timer stroke TA

mm

2.5

2.3

2.7

Timer stroke variation dT

mm

1.1

1.1

1.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

40.5

39.5

41.5

Timer stroke TA

mm

2.5

2.2

2.8

Timer stroke variation dT

mm

1.1

1.1

1.1

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

20

17.5

22.5

Timer stroke TA

mm

1.4

0.9

1.9

Timer stroke variation dT

mm

2.2

2.2

2.2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.62

5.52

5.72

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

33

28

38

Test data Ex:

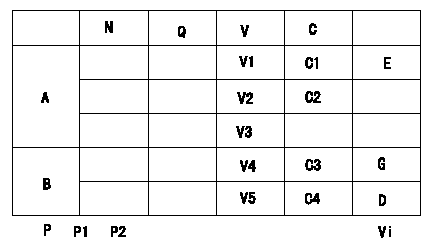

0000001801 POTENTIOMETER ADJUSTMENT

A:Potentiometer standards

B:ON, OFF switch standard

G:ON-->OFF

D:OFF-->ON

E:Adjusting point

F:Checking point

P:Boost pressure

Vi:Applied voltage

C2:Full-speed

C1:Idle

Q:Injection quantity

N:Pump speed

V:Output voltage

C:Control lever angle

Switch voltage is the value when the idle lever position is 0 V.

----------

----------

V1=1.6+-0.03V V2=7.1+-1.0V V3=-V V4=1.02+-0.41V V5=3.32+-0.5 C3=6.1+-2.5deg C4=19.9+-3.0deg Vi=10V P1=-kPa P2=-mmHg

----------

----------

V1=1.6+-0.03V V2=7.1+-1.0V V3=-V V4=1.02+-0.41V V5=3.32+-0.5 C3=6.1+-2.5deg C4=19.9+-3.0deg Vi=10V P1=-kPa P2=-mmHg

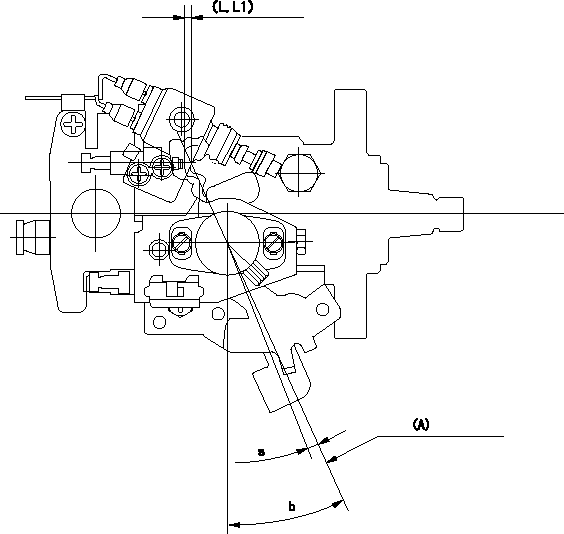

0000001901 ACCELERATOR SWITCH ADJ

Adjustment of the accelerator switch

ON-OFF changeover point: c (L, L1) from idle

Idle to d: ON

e~full: OFF

L:Thickness of the shim

(A): Position of the idle lever

----------

c=5+2-1deg d=5deg e=5deg L1=3.3+-0.13mm

----------

a=5+2-1deg b=23+-2deg L1=3.3mm

----------

c=5+2-1deg d=5deg e=5deg L1=3.3+-0.13mm

----------

a=5+2-1deg b=23+-2deg L1=3.3mm

Information:

Checking Field Coil for Insulation(3) Inspecting the stator coil(a) Check for conduction between lead wires of the stator coil. If there is no conduction, the stator coil is suspected to be broken. Replace the stator coil.

Checking Stator Coil for Conduction(b) Check for conduction between each lead wire and stator core. If any conduction is found, the stator coil is suspected to be poor in insulation. Replace the stator coil.

Checking Stator Coil for InsulationAssembly of Alternator

Reassemble the alternator assembly in the reverse order of disassembly, giving care to the following:(1) The rear bearing has an eccentric groove. Install the snap ring so that its projection fits in with the deepest part of the groove.(2) When installing a new rear bearing, press-fit the bearing with its groove facing the slip ring side.(3) When press-fitting the rear bearing into the rear bracket, heat the bracket. CAUTION* Pass a wire through the small hole in the rear bracket to lift the brushes before installing the rotor to the rear bracket. Remove the wire after the rotor is installed.

Lifting BrushesInstallation

Install the alternator in the reverse order of removal.(1) Insertion of spacerWhen installing the support bolts, insert the spacer in place using the following procedure:(a) Push in the support bolts to the normal position. (Leave the nuts removed from the bolts.)(b) Push the alternator backward. Measure the clearance between the alternator rear bracket and gear case bracket to determine the number of spacers to be inserted into the clearance (0.2 mm maximum).(c) Reinstall the alternator with the necessary spacer inserted in place. Tighten the support bolt nuts securely.(d) Perform the belt tension adjustment.

Inserting SpacerDynamo, Regulator and Rectifier

Specifications

For specifications, see 7-01.Inspection

(1) Checking the unit in serviceMeasure battery voltage across terminals with a circuit tester. It is considered normal if no-load measurement is kept steady at about 15.0V at 5000rpm or more of alternator speed.

Measuring Voltage Across Battery Terminals(2) Checking the regulator aloneTo judge whether the regulator itself is acceptable or not, check the regulator for normal conduction by connecting the circuit tester to the lead wires as follows. For testing, use the circuit tester as an ohmmeter.

Lead Outlet CouplerInstallation

(1) Heat affects largely on the regulator and rectifier. Position them in a well-ventilated place. Install the regulator in proper direction so that the outlet of leads from the body faces downward.GLOW PLUG

Removal and Installation

Glow plug tightening torque: 1.5 - 2.0 kgmInspection

Check for conduction between the glow plug terminal and body. If the plug is not conductive at all or shows a large resistance, replace the plug.

Checking Glow PlugKEY-OFF STOP SYSTEM

General

The function of this system is to actuate the fuel cutoff solenoid when the starter key is placed in the OFF position. It also has the emergency engine stop function by actuating the control timer in case of abnormal lowering of oil pressure (and abnormal increase of coolant temperature for special-specification engines).Control Timer Unit

Timer UnitFuel Cutoff Solenoid (Push type)

(1) Specification

Fuel Cutoff Solenoid (Push type)(2) Solenoid installation procedure(a) Temporarily fit the solenoid (1) and nut (2) to the

Have questions with 104741-4720?

Group cross 104741-4720 ZEXEL

Nissan-Diesel

104741-4720

9 460 614 435

1670058N16

INJECTION-PUMP ASSEMBLY

QD32

QD32