Information injection-pump assembly

BOSCH

9 460 614 430

9460614430

ZEXEL

104741-4471

1047414471

NISSAN

1670058N13

1670058n13

Rating:

Cross reference number

BOSCH

9 460 614 430

9460614430

ZEXEL

104741-4471

1047414471

NISSAN

1670058N13

1670058n13

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

56.4

55.9

56.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

49.8

46.3

53.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

52.9

49.4

56.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

56.4

55.4

57.4

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

54.6

51.6

57.6

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

54.8

51.8

57.8

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

20.1

18.1

22.1

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

20.1

17.6

22.6

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.9

5.9

9.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.9

5.4

10.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

75

110

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

75

110

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity with S/T ON

cm3/min

500

370

630

Oil temperature

degC

50

48

52

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

618

579

657

Pressure with S/T ON

kgf/cm2

6.3

5.9

6.7

Pressure with S/T OFF

kPa

539

519

559

Pressure with S/T OFF

kgf/cm2

5.5

5.3

5.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure with S/T OFF

kPa

539

500

578

Pressure with S/T OFF

kgf/cm2

5.5

5.1

5.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

686

647

725

Pressure with S/T OFF

kgf/cm2

7

6.6

7.4

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

6.3

5.9

6.7

Timer stroke with S/T OFF

mm

4.7

4.5

4.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

600

600

600

Timer stroke with S/T OFF

mm

1.7

1.2

2.2

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke with S/T ON

mm

6.3

5.8

6.8

Timer stroke with S/T OFF

mm

4.7

4.4

5

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

7.8

7.3

8.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1900

1900

1900

Timer stroke with S/T OFF

mm

9

8.5

9.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

32

31.5

32.5

Timer stroke TA

mm

3.9

3.7

4.1

Timer stroke variation dT

mm

0.8

0.8

0.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

32

31

33

Timer stroke TA

mm

3.9

3.6

4.2

Timer stroke variation dT

mm

0.8

0.8

0.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

20

17.5

22.5

Timer stroke TA

mm

2.7

2.2

3.2

Timer stroke variation dT

mm

2

2

2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.62

5.52

5.72

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

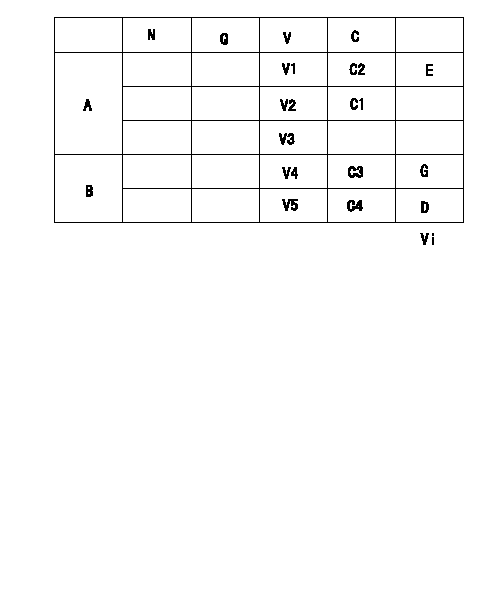

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

A:Potentiometer standards

B:ON, OFF switch standard

N:Pump speed

Q:Injection quantity

V:Output voltage

C:Control lever angle

C1:Full-speed

C2:Idle

E:Adjusting point

G:ON-->OFF

D:OFF-->ON

Vi:Applied voltage

----------

----------

V1=1.04+-0.03(V) V2=7.04+-1.0(V) V3=-(V) V4=1.59+-0.41(V) V5=3.89+-0.5(V) C3=9.5+-2.5(deg) C4=23.3+-3(deg) Vi=10(V)

----------

----------

V1=1.04+-0.03(V) V2=7.04+-1.0(V) V3=-(V) V4=1.59+-0.41(V) V5=3.89+-0.5(V) C3=9.5+-2.5(deg) C4=23.3+-3(deg) Vi=10(V)

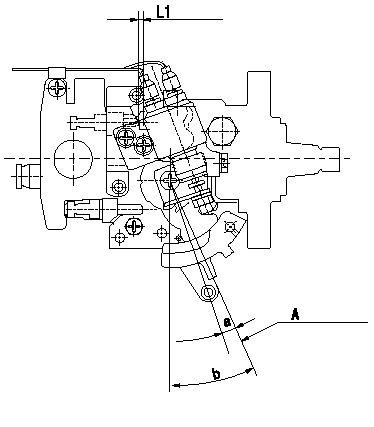

0000001901 ACCELERATOR SWITCH ADJ

Adjustment of the accelerator switch

ON - OFF changeover point: from idle to c (shim thickness L1 mm)

Idle-d: ON

e-full: OFF

A = idle lever position

----------

c=5+2-1(deg) d=5(deg) e=5(deg) L1=3.3+-0.13(mm)

----------

a=5+2-1(deg) b=23+-2(deg) L1=(3.3(mm))

----------

c=5+2-1(deg) d=5(deg) e=5(deg) L1=3.3+-0.13(mm)

----------

a=5+2-1(deg) b=23+-2(deg) L1=(3.3(mm))

Information:

Determination Of Overhaul Timing

Generally, the engine needs an overhaul when the compression pressure of the engine becomes low, and the amounts of engine oil consumption and blow-by gas increase.Reduced power output, increased fuel consumption, low oil pressure, difficult in starting, and increased operating noise are also signs that suggest the need for an overhaul; however, since these problems can be caused by various factors, they do not serve as reliable criteria for determining the need for an overhaul.Reduced compression pressure manifests a variety of symptoms, thus making it difficult to accurately determine when the engine needs an overhaul. The following shows typical problems caused by reduced compression pressure.(1) Decreased output power(2) Increased fuel consumption(3) Increased engine oil consumption(4) Increased blow-by gas from breather due to leakage of combustion gas through worn cylinder liners and piston rings(5) Increased gas leakage due to poor seating of inlet and exhaust valves(6) Difficulty in starting(7) Increased noise from engine parts(8) Abnormal exhaust color after warm-up operationThe engine can exhibit these conditions in various combinations.Some of these problems are directly caused by worn engine parts, while others are not.Phenomena described in (2) and (6) can also result from improper injection volume, incorrect fuel injection timing, worn plungers, defective nozzles, and faulty conditions of electrical devices such as battery, starter and alternator.The most valid reason to overhaul an engine is a decrease in the compression pressure due to worn cylinder liners and pistons, as described in (4), and once this is determined, other symptoms should be taken into consideration in order to make the final judgement of whether the engine needs an overhaul.Measurement of Compression Pressure

Measurement of compression pressurePreparation For Inspection

Check the following before inspection.(1) Make sure that the engine oil, air cleaner, starter, battery, etc. are in normal operating condition.Inspection

(1) Move the control lever to the Stop position.(2) Remove the glow plugs from all cylinders, and attach the gage adapter and compression gage to the cylinder to be tested.(3) Crank the engine with the starter, and read the compression gage indication when the indication stabilizes.(4) If the measured compression pressure is lower than the limit, consider overhauling the engine.

(a) Measure the compression pressure in all cylinders.(b) As compression pressure varies with the engine speed, measure the engine speed at the same time.

Measure the compression pressure while the engine is running at 150 to 200 min-1. The oil and coolant temperatures should be between 20 and 30 °C [68 and 86°F].

It is important to regularly check the compression pressure so that you can tell the difference. * New or overhauled engines have slightly higher compression pressure.* The compression pressure settles to the standard value as the piston rings and valve seats fit in.* As wear progresses further, the compression pressure drops.

Generally, the engine needs an overhaul when the compression pressure of the engine becomes low, and the amounts of engine oil consumption and blow-by gas increase.Reduced power output, increased fuel consumption, low oil pressure, difficult in starting, and increased operating noise are also signs that suggest the need for an overhaul; however, since these problems can be caused by various factors, they do not serve as reliable criteria for determining the need for an overhaul.Reduced compression pressure manifests a variety of symptoms, thus making it difficult to accurately determine when the engine needs an overhaul. The following shows typical problems caused by reduced compression pressure.(1) Decreased output power(2) Increased fuel consumption(3) Increased engine oil consumption(4) Increased blow-by gas from breather due to leakage of combustion gas through worn cylinder liners and piston rings(5) Increased gas leakage due to poor seating of inlet and exhaust valves(6) Difficulty in starting(7) Increased noise from engine parts(8) Abnormal exhaust color after warm-up operationThe engine can exhibit these conditions in various combinations.Some of these problems are directly caused by worn engine parts, while others are not.Phenomena described in (2) and (6) can also result from improper injection volume, incorrect fuel injection timing, worn plungers, defective nozzles, and faulty conditions of electrical devices such as battery, starter and alternator.The most valid reason to overhaul an engine is a decrease in the compression pressure due to worn cylinder liners and pistons, as described in (4), and once this is determined, other symptoms should be taken into consideration in order to make the final judgement of whether the engine needs an overhaul.Measurement of Compression Pressure

Measurement of compression pressurePreparation For Inspection

Check the following before inspection.(1) Make sure that the engine oil, air cleaner, starter, battery, etc. are in normal operating condition.Inspection

(1) Move the control lever to the Stop position.(2) Remove the glow plugs from all cylinders, and attach the gage adapter and compression gage to the cylinder to be tested.(3) Crank the engine with the starter, and read the compression gage indication when the indication stabilizes.(4) If the measured compression pressure is lower than the limit, consider overhauling the engine.

(a) Measure the compression pressure in all cylinders.(b) As compression pressure varies with the engine speed, measure the engine speed at the same time.

Measure the compression pressure while the engine is running at 150 to 200 min-1. The oil and coolant temperatures should be between 20 and 30 °C [68 and 86°F].

It is important to regularly check the compression pressure so that you can tell the difference. * New or overhauled engines have slightly higher compression pressure.* The compression pressure settles to the standard value as the piston rings and valve seats fit in.* As wear progresses further, the compression pressure drops.