Information injection-pump assembly

BOSCH

9 460 614 429

9460614429

ZEXEL

104741-4461

1047414461

NISSAN

1670058N12

1670058n12

Rating:

Cross reference number

BOSCH

9 460 614 429

9460614429

ZEXEL

104741-4461

1047414461

NISSAN

1670058N12

1670058n12

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

56.4

55.9

56.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

49.8

46.3

53.3

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

52.9

49.4

56.4

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

56.4

55.4

57.4

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

54.6

51.6

57.6

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

54.8

51.8

57.8

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

20.1

18.1

22.1

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

20.1

17.6

22.6

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.9

5.9

9.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.9

5.4

10.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

75

110

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

75

110

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

Speed control lever angle_02

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

5

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at full-load position

Magnet OFF at full-load position

0000000901

Pump speed

r/min

1000

1000

1000

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

539

519

559

Pressure

kgf/cm2

5.5

5.3

5.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1000

1000

1000

Pressure

kPa

539

500

578

Pressure

kgf/cm2

5.5

5.1

5.9

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1600

1600

1600

Pressure

kPa

686

647

725

Pressure

kgf/cm2

7

6.6

7.4

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

4.7

4.5

4.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

600

600

600

Timer stroke

mm

2.4

1.9

2.9

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

4.7

4.4

5

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1600

1600

1600

Timer stroke

mm

7.8

7.3

8.3

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1900

1900

1900

Timer stroke

mm

9

8.5

9.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

32

31.5

32.5

Timer stroke TA

mm

3.9

3.7

4.1

Timer stroke variation dT

mm

0.8

0.8

0.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

32

31

33

Timer stroke TA

mm

3.9

3.6

4.2

Timer stroke variation dT

mm

0.8

0.8

0.8

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

20

17.5

22.5

Timer stroke TA

mm

2.7

2.2

3.2

Timer stroke variation dT

mm

2

2

2

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.62

5.52

5.72

MS dimension

mm

0.9

0.8

1

Pre-stroke

mm

0.1

0.08

0.12

Control lever angle alpha

deg.

55.5

53.5

57.5

Control lever angle beta

deg.

36

31

41

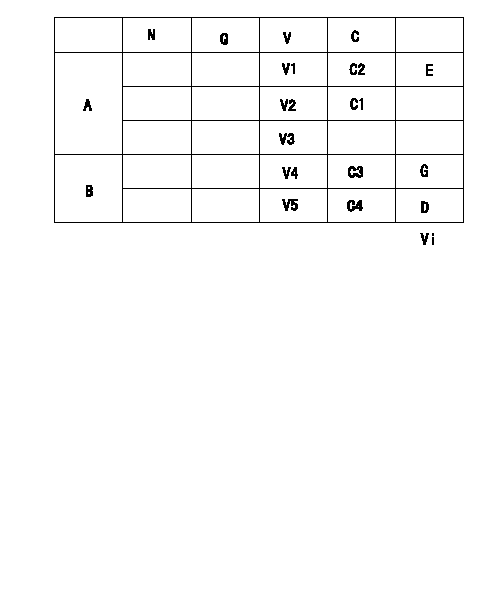

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

A:Potentiometer standards

B:ON, OFF switch standard

N:Pump speed

Q:Injection quantity

V:Output voltage

C:Control lever angle

C1:Full-speed

C2:Idle

E:Adjusting point

G:ON-->OFF

D:OFF-->ON

Vi:Applied voltage

*The switch voltage specification is the value when the idle lever position is 0 volts.

----------

----------

V1=1.04+-0.03(V) V2=7.04+-1.0(V) V3=-(V) V4=1.59+-0.41(V) V5=3.89+-0.5(V) C3=9.5+-2.5(deg) C4=23.3+-3(deg) Vi=10(V)

----------

----------

V1=1.04+-0.03(V) V2=7.04+-1.0(V) V3=-(V) V4=1.59+-0.41(V) V5=3.89+-0.5(V) C3=9.5+-2.5(deg) C4=23.3+-3(deg) Vi=10(V)

Information:

ACTION REQUIRED

Flash engine ECM with new 422-8397 Software on machines located in North America.

Flash engine ECM with new 422-8398 Software on machines located in Europe.

Refer to Special Instruction, REHS7927 for instructions on replacing the diesel particulate filter pressure lines group.

Refer to Special Instruction, REHS7197 for instructions on installing the engine cooling fan bypass feature.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-5000 hrs,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 12.0-hour job for Group 1

Travel and mileage will be allowed under this program

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-5000 hrs,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 12.0-hour job for Group 2

Travel and mileage will be allowed under this program

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.