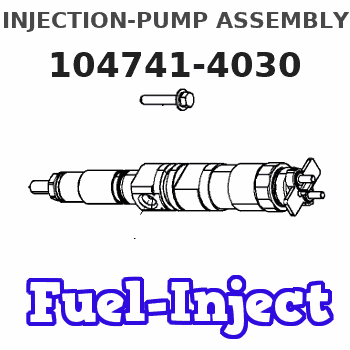

Information injection-pump assembly

BOSCH

9 460 614 424

9460614424

ZEXEL

104741-4030

1047414030

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-4030 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Include in #2:

104741-4030

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 614 424

9460614424

ZEXEL

104741-4030

1047414030

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

(Note)

For Japan: year/month/day (change sequence) 1988/12/7(2)

For Japan: year/month/day (change sequence) 1988/12/7(2)

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54.9

54.4

55.4

Difference in delivery

mm3/st.

4.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

18.1

14.6

21.6

Injection timing adjustment_03

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

50.95

48.5

53.4

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54.9

53.9

55.9

Injection timing adjustment_05

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

51.55

49.5

53.6

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54.6

54.1

55.1

Difference in delivery

mm3/st.

4.5

Basic

*

Remarks

For Japan

For Japan

Injection timing adjustment_07

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

17.7

14.2

21.2

Remarks

For Japan

For Japan

Injection timing adjustment_08

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

52.1

49.7

54.5

Remarks

For Japan

For Japan

Injection timing adjustment_09

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

54.6

53.6

55.6

Remarks

For Japan

For Japan

Injection timing adjustment_10

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

51.4

49.4

53.4

Remarks

For Japan

For Japan

Injection quantity adjustment

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

18.1

15.1

21.1

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

3

Injection quantity adjustment_03

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

17.7

14.7

20.7

Basic

*

Remarks

For Japan

For Japan

Injection quantity adjustment_04

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

3

Remarks

For Japan

For Japan

Governor adjustment

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10.25

8.2

12.3

Difference in delivery

mm3/st.

3

Basic

*

Governor adjustment_02

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10.25

8.2

12.3

Governor adjustment_03

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

3

Governor adjustment_04

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10

8

12

Difference in delivery

mm3/st.

3

Basic

*

Remarks

For Japan

For Japan

Governor adjustment_05

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

10

8

12

Remarks

For Japan

For Japan

Governor adjustment_06

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

3

Remarks

For Japan

For Japan

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

56

56

Basic

*

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

55

55

Basic

*

Remarks

For Japan

For Japan

Speed control lever angle

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

Speed control lever angle_02

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

0

0

0

Remarks

For Japan: Magnet OFF

For Japan: Magnet OFF

0000000901

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

363

240

486

_02

Pump speed

r/min

1000

1000

1000

Overflow quantity

cm3/min

381

252

510

Remarks

For Japan

For Japan

Stop lever angle

Pump speed

r/min

1000

1000

1000

Pressure

kPa

451.5

422

481

Pressure

kgf/cm2

4.6

4.3

4.9

Basic

*

Stop lever angle_02

Pump speed

r/min

500

500

500

Pressure

kPa

294.5

265

324

Pressure

kgf/cm2

3

2.7

3.3

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure

kPa

451.5

422

481

Pressure

kgf/cm2

4.6

4.3

4.9

Stop lever angle_04

Pump speed

r/min

1800

1800

1800

Pressure

kPa

686.5

657

716

Pressure

kgf/cm2

7

6.7

7.3

Stop lever angle_05

Pump speed

r/min

1000

1000

1000

Pressure

kPa

441.5

412

471

Pressure

kgf/cm2

4.5

4.2

4.8

Basic

*

Remarks

For Japan

For Japan

Stop lever angle_06

Pump speed

r/min

500

500

500

Pressure

kPa

284.5

255

314

Pressure

kgf/cm2

2.9

2.6

3.2

Remarks

For Japan

For Japan

Stop lever angle_07

Pump speed

r/min

1000

1000

1000

Pressure

kPa

441.5

412

471

Pressure

kgf/cm2

4.5

4.2

4.8

Remarks

For Japan

For Japan

Stop lever angle_08

Pump speed

r/min

1800

1800

1800

Pressure

kPa

676.5

647

706

Pressure

kgf/cm2

6.9

6.6

7.2

Remarks

For Japan

For Japan

0000001101

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.4

1.2

1.6

Basic

*

_02

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.4

1.1

1.7

_03

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

3.4

2.8

4

_04

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

5

4.5

5.5

_05

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.4

1.2

1.6

Basic

*

Remarks

For Japan

For Japan

_06

Pump speed

r/min

1000

1000

1000

Timer stroke

mm

1.4

1.1

1.7

Remarks

For Japan

For Japan

_07

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

3.3

2.7

3.9

Remarks

For Japan

For Japan

_08

Pump speed

r/min

1800

1800

1800

Timer stroke

mm

4.9

4.4

5.4

Remarks

For Japan

For Japan

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.1

1

1.2

Control lever angle alpha

deg.

25

21

29

Control lever angle beta

deg.

36

31

41

Information:

Use of the convenient tip (measure) and pour container allows accurate dilution in all sizes of equipment. 1 ounce of Caterpillar Diesel Fuel Conditioner treats 11 gallons of diesel fuel (one 32-ounce container will treat 350 gallons of diesel fuel).

The conditioner comes in a case of six 32-ounce containers.

As sulfur restrictions become more stringent, Caterpillar

?

Diesel Fuel Conditioner will help compensate for reduced lubricity found in some low sulfur diesel fuels. It will also improve combustion, fuel storage stability, and fuel system life.

Gary Coker

Product Support Division

Product Support

(309)578-8249

Coker_Gary_D

PELJ0525 CATERPILLAR? ?2005 Caterpillar