Information injection-pump assembly

ZEXEL

104741-3891

1047413891

Rating:

Cross reference number

ZEXEL

104741-3891

1047413891

Zexel num

Bosch num

Firm num

Name

104741-3891

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58.5

58

59

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

71.5

71

72

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Average injection quantity

mm3/st.

83.1

82.6

83.6

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

58.5

57.5

59.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

750

750

750

Boost pressure

kPa

53.3

52

54.6

Boost pressure

kgf/cm2

0.54

0.526

0.554

Boost pressure

mmHg

400

390

410

Average injection quantity

mm3/st.

71.5

70.5

72.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Average injection quantity

mm3/st.

83.1

82.1

84.1

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Average injection quantity

mm3/st.

71

67

75

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2475

2475

2475

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Average injection quantity

mm3/st.

26.4

23.4

29.4

Difference in delivery

mm3/st.

8

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Average injection quantity

mm3/st.

8

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2475

2475

2475

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Average injection quantity

mm3/st.

26.4

21.4

31.4

Difference in delivery

mm3/st.

8.5

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

18.9

16.9

20.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

18.9

16.4

21.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

150

150

150

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

78.1

58.1

98.1

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

150

150

150

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

78.1

58.1

98.1

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

kgf/cm2

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Overflow quantity with S/T ON

cm3/min

740

610

870

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Pressure with S/T ON

kPa

647

608

686

Pressure with S/T ON

kgf/cm2

6.6

6.2

7

Pressure with S/T OFF

kPa

500

480

520

Pressure with S/T OFF

kgf/cm2

5.1

4.9

5.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

0000001101

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Timer stroke with S/T ON

mm

6.8

6.3

7.3

Timer stroke with S/T OFF

mm

3.4

3.2

3.6

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Timer stroke with S/T ON

mm

3.9

3.2

4.6

Timer stroke with S/T OFF

mm

1

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Timer stroke with S/T OFF

mm

2

1.3

2.7

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Timer stroke with S/T ON

mm

6.8

6.1

7.5

Timer stroke with S/T OFF

mm

3.4

3

3.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Timer stroke with S/T OFF

mm

6.3

5.6

7

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

86.6

85.3

87.9

Boost pressure

kgf/cm2

0.88

0.866

0.894

Boost pressure

mmHg

650

640

660

Timer stroke with S/T ON

mm

8.6

8.1

9

Timer stroke with S/T OFF

mm

8

7.3

8.7

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

5.1

4.9

5.3

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

42

37

47

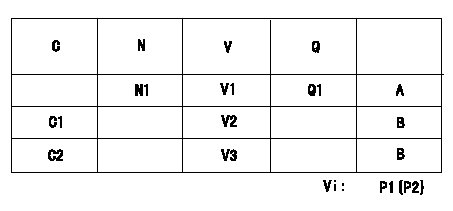

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Adjusting method (service voltage Vi, dummy bolt):

1. Hold the dummy bolt against the control lever when N = N1 r/min, Q = Q1 mm3/st.

Fix using the lock nut.

2. When adjusting the potentiometer, position the control lever against the dummy bolt and adjust the potentiometer so that the output voltage is V1 (V).

3. Remove the dummy bolt after the completion of adjustment.

Confirm that the potentiometer output voltage is within the standards mentioned when the control lever is idling and in full-speed position.

Vi:Applied voltage

C:Position of the control lever

N:Pump speed (r/min)

V:Output voltage (V)

Q:Injection quantity (mm3/st)

A:Adjusting point

B:Checking point

C1:Idling

C2:Full speed

P1:Boost pressure

P2:Boost pressure

----------

N1=750r/min V1=5.10+-0.03V Q1=34.7+-1.0cm3/1,000st

----------

N1=750r/min V1=5.10+-0.03V V2=2.16+-0.52V V3=9.02+-0.72V Q1=34.7+-1.0cm3/1,000st Vi=10V P1=-kPa P2=-mmHg

----------

N1=750r/min V1=5.10+-0.03V Q1=34.7+-1.0cm3/1,000st

----------

N1=750r/min V1=5.10+-0.03V V2=2.16+-0.52V V3=9.02+-0.72V Q1=34.7+-1.0cm3/1,000st Vi=10V P1=-kPa P2=-mmHg

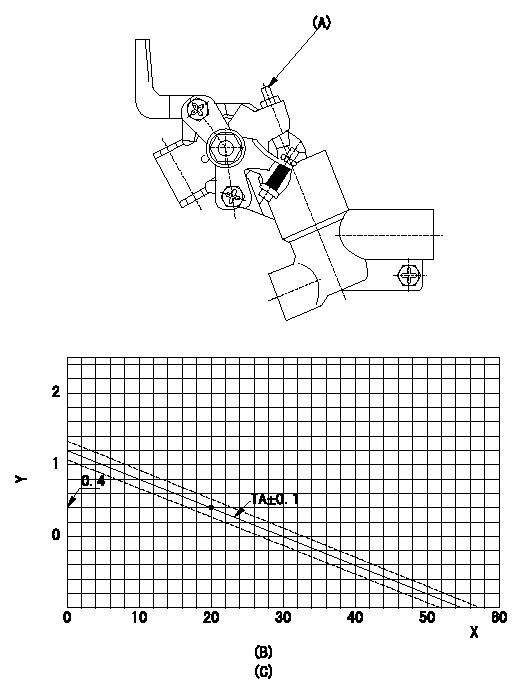

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the following graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(B): Timer stroke TA (mm):

----------

----------

(B)=TA=-0.04t+1.2(0<=t<=30)

----------

----------

(B)=TA=-0.04t+1.2(0<=t<=30)

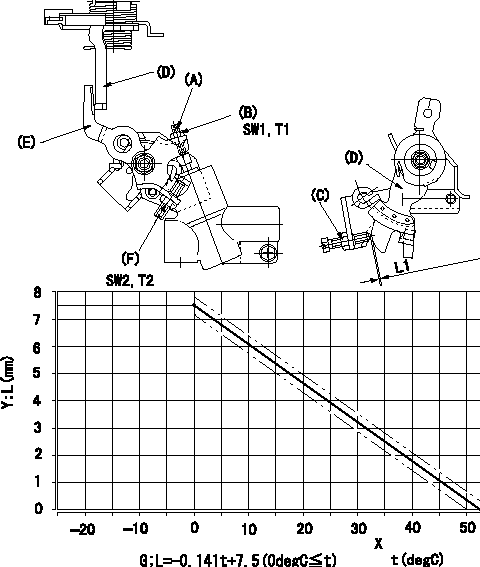

0000002001 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L1 determined from the graph below between the control lever (D) and the idle set screw (C).

(2)Tighten the nut (F) at the position where the W-FICD lever (E) the control lever (D) contact.

T2T2

(3)After adjusting the W-FICD lever (E), confirm that the timer stroke is the value adjusted in item 1. Then, remove the shim.

Y = control lever position

X = temperature

G = control lever position: (mm)

----------

L1=L+-0.3 mm T2=6~9 Nm{0.6~0.9 kgf}

----------

L1=L+-0.3 mm SW2=SW10 T2=6~9 Nm{0.6~0.9 kgfm} SW1=SW8 T1=3.4~4.9 Nm{0.35~0.5 kgfm}

----------

L1=L+-0.3 mm T2=6~9 Nm{0.6~0.9 kgf}

----------

L1=L+-0.3 mm SW2=SW10 T2=6~9 Nm{0.6~0.9 kgfm} SW1=SW8 T1=3.4~4.9 Nm{0.35~0.5 kgfm}

Information:

Features

Benefits

All critical engineering changes and updates included

Improved reliability and performance

Worldwide availability through Cat parts distribution system

Customer access regardless of location

Off-the-shelf availability

Downtime reduced through exchange product

Same-as-new Caterpillar warranty

Consistent support

Coverage Chart

Reman PN

New PN

Part Name

20R1298

3594090

INJECTOR GP - FUEL

20R1299

3494080

INJECTOR GP - FUEL

20R1301

3594020

INJECTOR GP - FUEL

20R1302

3594040

INJECTOR GP - FUEL

20R1303

3594070

INJECTOR GP - FUEL

20R1304

3597434

INJECTOR GP - FUEL

20R1308

3594050

INJECTOR GP - FUEL

20R1302

3594040

INJECTOR GP - FUEL

20R1317

3809889

INJECTOR GP - FUEL

20R1318

3674293

INJECTOR GP - FUEL

20R3247

3920225

INJECTOR GP - FUEL

20R3607

3820709

INJECTOR GP - FUEL

20R3608

3820745

INJECTOR GP – FUEL

20R3815

3689171

PUMP GP – FUEL INJ

20R3816

3689172

PUMP GP – FUEL INJ

20R3817

3689173

PUMP GP – FUEL INJ

Core Acceptance

The following Core Acceptance Criteria are available supporting these products. All the latest Core Acceptance Criteria guidelines can be found on the Reman Dealer Extranet at https://catreman.cat.com/cac

SELD0226 Unit Injectors Electronic

SELD0023 Fuel Pump & Governor Groups

Warranty

Please consult the appropriate warranty statement for your area by going to warranty.cat.com.

Core Management

Please refer to the Caterpillar Core Management Information System (CMIS 2) related to the parts information application that describes all Reman part/Core Acceptability Family (CAF) and other related information. Also, refer to other CMIS 2 inquiry applications such as: Dealer Customer Profile, Inspection Reason Codes, Inspection Line Inquiry, Dealer Add Charges, Dealer Entitlement Activity, Dealer CCR Inquiry, Dealer CCR Entry, Dealer Shipment Processing, Dealer Process Packaging Grief and Reporting. This information is available to all dealers worldwide that have been converted to CMIS 2.

Please go to the Reman web site https://catreman.cat.com for the latest policy and procedural updates that are available to all dealers worldwide explaining policy and procedural information such as “Policy and Core Management” -SELD0122; “Core Management Systems and Operations Procedures” -SELD0040; “Reman Core Return Packaging Instructions And Guidelines” -SELD0300; and “Shipping Instructions” SELD0039.

If you have any questions regarding Reman Core Management or Core Management Systems (CMIS2), feel free to call your Corinth Dealer Service Representative toll free at (800) 537-2928.

Contact Information:

For assistance with technical questions, call the Reman Technical Hot Line also toll free at (888) 88-REMAN or use our e-mail address--Reman_Help.

Global Dealer Solutions Network Parts Technical Support Team Toll Free -North America: 1-877-228-2420 International: +1-309-266-4421 Electronic Requests: Send via Microsoft Customer Relationship Management (MSCRM). For access and tutorial information: https://gdsn.cat.com/mscrm

, CATERPILLAR, BUILT FOR IT, their respective logos, “Caterpillar Yellow” and the ”Power Edge” trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

The information contained herein is intended for circulation only to Caterpillar and dealer employees whose duties require knowledge of such reports and is intended exclusively for their information and

Have questions with 104741-3891?

Group cross 104741-3891 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

104741-3891

INJECTION-PUMP ASSEMBLY