Information injection-pump assembly

ZEXEL

104741-3810

1047413810

Rating:

Cross reference number

ZEXEL

104741-3810

1047413810

Zexel num

Bosch num

Firm num

Name

104741-3810

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

57.1

56.6

57.6

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

46.7

45.4

48

Boost pressure

mmHg

350

340

360

Average injection quantity

mm3/st.

73.8

73.3

74.3

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

84.4

83.9

84.9

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

57.1

56.1

58.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_05

Pump speed

r/min

750

750

750

Boost pressure

kPa

46.7

45.4

48

Boost pressure

mmHg

350

340

360

Average injection quantity

mm3/st.

73.8

72.8

74.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

84.4

83.4

85.4

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

71.8

67.8

75.8

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2475

2475

2475

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

26.4

23.4

29.4

Difference in delivery

mm3/st.

8

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

8

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2475

2475

2475

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

26.4

21.4

31.4

Difference in delivery

mm3/st.

8.5

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

18.9

16.9

20.9

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

18.9

16.4

21.4

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

150

150

150

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

78.1

58.1

98.1

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

150

150

150

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

78.1

58.1

98.1

Oil temperature

degC

48

46

50

Remarks

Full

Full

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity

cm3/min

740

610

870

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

500

480

520

Pressure

kgf/cm2

5.1

4.9

5.3

Basic

*

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.7

3.5

3.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

1.7

1.1

2.3

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.7

3.3

4.1

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

6.9

6.3

7.5

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

8.6

8.1

9

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

5.5

5.3

5.7

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

41

36

46

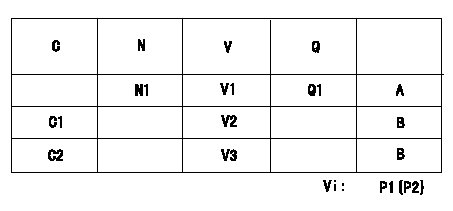

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Adjusting method (service voltage Vi, dummy bolt):

1. Hold the dummy bolt against the control lever when N = N1 r/min, Q = Q1 mm3/st.

Fix using the lock nut.

2. When adjusting the potentiometer, position the control lever against the dummy bolt and adjust the potentiometer so that the output voltage is V1 (V).

3. Remove the dummy bolt after the completion of adjustment.

Confirm that the potentiometer output voltage is within the standards mentioned when the control lever is idling and in full-speed position.

Vi:Applied voltage

C:Position of the control lever

N:Pump speed (r/min)

V:Output voltage (V)

Q:Injection quantity (mm3/st)

A:Adjusting point

B:Checking point

C1:Idling

C2:Full speed

P1:Boost pressure

P2:Boost pressure

----------

N1=750r/min V1=4.16+-0.03V Q1=34.7+-1.0cm3/1,000st

----------

N1=750(r/min) V1=4.16+-0.03(V) V2=2.16+-0.52(V) V3=9.02+-0.72(V) Q1=34.7+-1.0(mm3/st) Vi=10V

----------

N1=750r/min V1=4.16+-0.03V Q1=34.7+-1.0cm3/1,000st

----------

N1=750(r/min) V1=4.16+-0.03(V) V2=2.16+-0.52(V) V3=9.02+-0.72(V) Q1=34.7+-1.0(mm3/st) Vi=10V

Information:

Operations that may cause product damage are identified by notice labels in this publication.

Introduction

This Tool Operating Manual contains two filter installation procedures. This first procedure is for installing a primary filter system. This is a coarse filter and will protect the transfer pump from contamination in the oil. The second procedure outlines installing a secondary filter which is designed to protect injection pumps from contaminated oil. Fuel injection pumps used on the 3208 Engine are one example of a fuel injection pump that requires the secondary filter installation.It will be the dealer choice as to which optional filter is installed on the test stand. Determine what type of filtering will be required most often, and install the appropriate type of filtering system. These filters can only be added to the 15 horsepower test stands.Secondary Filter

Nomenclature

Illustration 1. Nomenclature for Secondary Filter Installation. Refer to Chart A for item identification. Fabricated Parts

All the parts required for this installation can be ordered from Caterpillar Parts Distribution, except bracket (1). This must be manufactured by the bench owner, using the dimensions provided below.This bracket can be made from common SAE1018 steel. Weld the two pieces together.

Illustration 2. Filter Mounting Bracket. Refer to Chart B for dimensions. Installation

Assemble the Fuel Filter

1. Install 053-0088 Fitting (17) with 3J-1907 Seal (18) into the inlet port (left side) of the filter base. (This converts a number 6 STOP port to NPT). Install 5P-4455 Fitting (19) into fitting (17).2. Install 2R-6806 Fitting (15) with 3J-1907 Seal (16) into the outlet port (right side) of the filter base.3. Install 6N-4414 Cover (7) onto the filter base using 1P-0436 Gasket (8), 4B-3388/6V-2317 (9), and OS-1616/6V-8490 Bolt (10).4. Install 9S-4182 Plug (5) with 6V-5084 O-ring Seal (6) into the top of the filter base.5. Install the filter base assembly onto filter bracket (1),

Have questions with 104741-3810?

Group cross 104741-3810 ZEXEL

Mitsubishi

104741-3810

INJECTION-PUMP ASSEMBLY