Information injection-pump assembly

BOSCH

9 460 613 652

9460613652

ZEXEL

104741-3321

1047413321

MITSUBISHI

ME201434

me201434

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-3321 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104641-3321 |

| 3. | NUMBER PLATE | 146956-7800 |

| 4. | _ | 479771-0520 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1301 |

| 8. | Nozzle and Holder | ME200204 |

| 9. | Open Pre:MPa(Kqf/cm2) | 14.7{150} |

| 10. | NOZZLE-HOLDER | 105078-0181 |

| 11. | NOZZLE | 105007-1290 |

Scheme ###:

| 1. | [1] | 146004-4420 | PUMP HOUSING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-1720 | PLAIN WASHER |

| 20. | [1] | 146210-3520 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-3220 | CAM PLATE |

| 30. | [1] | 146600-3000 | O-RING |

| 31. | [1] | 146311-8520 | PUMP PLUNGER |

| 32. | [1] | 146301-0200 | SLIDING PIECE |

| 34. | [1] | 146312-3900 | COMPRESSION SPRING |

| 34B. | [1] | 146312-2600 | COMPRESSION SPRING |

| 34C. | [1] | 146312-2900 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-3000 | O-RING |

| 37. | [1] | 146310-1600 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0901 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-3300 | COMPRESSION SPRING |

| 42. | [1] | 146602-8500 | PLAIN WASHER |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM D17&5.2T2.1 |

| 48/1. | [1] | 146690-5900 | SHIM D17&5.2T2.2 |

| 48/1. | [1] | 146690-6000 | SHIM D17&5.2T2.3 |

| 48/1. | [1] | 146690-6100 | SHIM D17&5.2T2.4 |

| 48/1. | [1] | 146690-6200 | SHIM D17&5.2T2.5 |

| 48/1. | [1] | 146690-6300 | SHIM D17&5.2T2.6 |

| 48/1. | [1] | 146690-6400 | SHIM D17&5.2T2.7 |

| 48/1. | [1] | 146690-6500 | SHIM D17&5.2T2.8 |

| 48/1. | [1] | 146690-6600 | SHIM D17&5.2T2.9 |

| 48/1. | [1] | 146690-6700 | SHIM D17&5.2T3.0 |

| 48/1. | [1] | 146690-6800 | SHIM D17&5.2T3.1 |

| 48/1. | [1] | 146690-6900 | SHIM D17&5.2T3.2 |

| 48/1. | [1] | 146690-7000 | SHIM D17&5.2T3.3 |

| 48/1. | [1] | 146690-7100 | SHIM D17&5.2T3.4 |

| 48/1. | [1] | 146690-7200 | SHIM D17&5.2T0.4 |

| 48/1. | [1] | 146690-7300 | SHIM D17&5.2T0.6 |

| 48/1. | [1] | 146690-7400 | SHIM D17&5.2T0.7 |

| 48/1. | [1] | 146690-7500 | SHIM D17&5.2T1.9 |

| 48/1. | [1] | 146690-7800 | SHIM D17&5.2T0.2 |

| 49. | [2] | 146234-0120 | GUIDE PIN |

| 50. | [1] | 146403-4920 | HYDRAULIC HEAD |

| 50. | [1] | 146403-4920 | HYDRAULIC HEAD |

| 50. | [1] | 146403-4920 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-4820 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146703-3120 | COMPENSATOR,MANIFOLD-PRES |

| 67/1. | [1] | 146805-8320 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/23. | [1] | 146930-9422 | BRACKET |

| 67/24. | [2] | 010206-1440 | HEX-SOCKET-HEAD CAP SCREW M6P1L14 |

| 67/31. | [1] | 146710-0700 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-0700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET D8.9&6.8T1.00 |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 67/41. | [1] | 146713-4300 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0200 | PLATE |

| 67/43. | [1] | 146715-0300 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-2900 | COILED SPRING |

| 67/48/1. | [1] | 146720-3000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-3100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-3200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-3300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-3400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-3500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-3600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-3700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-3800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-3900 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-4000 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146720-4100 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146720-4200 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146720-4300 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146720-4400 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146720-8900 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146720-9000 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146720-9100 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146720-9200 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146720-9300 | SPACER BUSHING L7.5 |

| 67/48/1. | [1] | 146720-9400 | SPACER BUSHING L7.7 |

| 67/48/1. | [1] | 146720-9500 | SPACER BUSHING L7.9 |

| 67/48/1. | [1] | 146720-9600 | SPACER BUSHING L8.1 |

| 67/48/1. | [1] | 146720-9700 | SPACER BUSHING L8.3 |

| 67/48/1. | [1] | 146720-9800 | SPACER BUSHING L8.5 |

| 67/48/1. | [1] | 146720-9900 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146725-0000 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146725-0100 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146725-0200 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146725-0300 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146725-0400 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146725-0500 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146725-0600 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146725-0700 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146725-0800 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146725-0900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146725-1000 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-1100 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-1200 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-1300 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-1400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-1500 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-1600 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-1700 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-1800 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-1900 | SPACER BUSHING L7.6 |

| 67/48/1. | [1] | 146725-2000 | SPACER BUSHING L7.8 |

| 67/48/1. | [1] | 146725-2100 | SPACER BUSHING L8.0 |

| 67/48/1. | [1] | 146725-2200 | SPACER BUSHING L8.2 |

| 67/48/1. | [1] | 146725-2300 | SPACER BUSHING L8.4 |

| 67/48/1. | [1] | 146725-2400 | SPACER BUSHING L8.6 |

| 67/49. | [1] | 146721-3621 | COVER |

| 67/50. | [1] | 146722-0200 | FLAT-HEAD SCREW |

| 67/51. | [1] | 146600-0300 | O-RING |

| 67/53. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/54. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/54. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/55. | [2] | 139006-4800 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0300 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146930-8900 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/94. | [1] | 146926-7600 | BRACKET |

| 67/96. | [1] | 146930-9220 | BRACKET |

| 67/98. | [2] | 146648-2800 | SPACER BUSHING |

| 67/102. | [1] | 146930-9000 | BRACKET |

| 67/112. | [1] | 146930-9100 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146514-7120 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146830-6920 | CONTROL LEVER |

| 72B. | [1] | 146830-7020 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146865-0520 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146575-6300 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-7620 | PULLING ELECTROMAGNET |

| 137. | [2] | 029331-4010 | GASKET |

| 145. | [1] | 146621-1000 | UNION NUT |

| 147. | [1] | 016520-1210 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 217. | [1] | 146542-5300 | SLOTTED WASHER |

| 218. | [1] | 146592-2500 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2600 | COILED SPRING |

| 224. | [1] | 139006-4400 | BLEEDER SCREW |

| 229. | [1] | 146613-8300 | JOINT CONNECTION |

| 230. | [1] | 146629-0200 | BRACKET |

| 231. | [1] | 139006-4400 | BLEEDER SCREW |

| 233. | [1] | 146662-3720 | WIRE |

| 235. | [1] | 146931-6100 | BRACKET |

| 236. | [1] | 139006-4700 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 146931-7220 | BRACKET |

| 245. | [3] | 026512-1840 | GASKET D17.9&12.2T1.50 |

| 245. | [3] | 026512-1840 | GASKET D17.9&12.2T1.50 |

| 246. | [1] | 139812-1900 | EYE BOLT |

| 247. | [1] | 146666-6820 | PIPE |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146612-7420 | BRACKET |

| 276. | [2] | 010010-2040 | BLEEDER SCREW M10P1.5L20 |

| 280. | [1] | 146361-2820 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 294. | [1] | 146666-7520 | INLET UNION |

| 310. | [1] | 146673-9922 | POTENTCIOMETER |

| 310/2. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/3. | [1] | 146648-2900 | JOINT CONNECTION |

| 310/3B. | [1] | 146648-3000 | JOINT CONNECTION |

| 310/3C. | [1] | 146648-3100 | JOINT CONNECTION |

| 310/3D. | [1] | 146648-3200 | JOINT CONNECTION |

| 310/3E. | [1] | 146648-3300 | JOINT CONNECTION |

| 310/3F. | [1] | 146648-4700 | JOINT CONNECTION |

| 310/3G. | [1] | 146648-5300 | JOINT CONNECTION |

| 310/3H. | [1] | 146649-1700 | JOINT CONNECTION |

| 310/4. | [1] | 146661-0601 | BOOT |

| 312. | [1] | 146932-0620 | BRACKET |

| 313. | [1] | 020106-1240 | BLEEDER SCREW M6P1.0L12 |

| 344. | [1] | 146666-7620 | INLET UNION |

| 800S. | [1] | 146018-5020 | PUMP HOUSING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146672-2820 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146956-7800 | NAMEPLATE |

| 910S. | [1] | 146600-4320 | PARTS SET |

| 910S. | [1] | 146600-4320 | PARTS SET |

| 911S. | [1] | 146672-2820 | PULSE GENERATOR |

| 911S/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 912S. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 913S. | [1] | 146422-0000 | BLEEDER SCREW |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 915S. | [1] | 146662-3720 | WIRE |

| 916S. | [1] | 025804-1610 | WOODRUFF KEY |

| 917S. | [1] | 146684-2310 | POTENTCIOMETER |

Include in #2:

104741-3321

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 613 652

9460613652

ZEXEL

104741-3321

1047413321

MITSUBISHI

ME201434

me201434

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

600

600

600

Boost pressure

kPa

31.3

30

32.6

Boost pressure

mmHg

235

225

245

Average injection quantity

mm3/st.

67.3

66.8

67.8

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

57.2

56.7

57.7

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

81.3

80.8

81.8

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

600

600

600

Boost pressure

kPa

31.3

30

32.6

Boost pressure

mmHg

235

225

245

Average injection quantity

mm3/st.

67.3

66.3

68.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_05

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

57.2

56.2

58.2

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

81.3

80.3

82.3

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

75.8

72.3

79.3

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

53.3

51.8

54.8

Difference in delivery

mm3/st.

17

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

12

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.8

51.8

61.8

Difference in delivery

mm3/st.

17.5

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.4

10.4

14.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.4

9.9

14.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

150

150

150

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52

42

62

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

150

150

150

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52

42

62

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity with S/T ON

cm3/min

740

610

870

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T ON

kPa

559

520

598

Pressure with S/T ON

kgf/cm2

5.7

5.3

6.1

Pressure with S/T OFF

kPa

510

490

530

Pressure with S/T OFF

kgf/cm2

5.2

5

5.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T OFF

kPa

373

324

422

Pressure with S/T OFF

kgf/cm2

3.8

3.3

4.3

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T ON

kPa

559

510

608

Pressure with S/T ON

kgf/cm2

5.7

5.2

6.2

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_04

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T OFF

kPa

667

618

716

Pressure with S/T OFF

kgf/cm2

6.8

6.3

7.3

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T ON

mm

6.6

6.1

7.1

Timer stroke with S/T OFF

mm

5.5

5.3

5.7

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T ON

mm

3.3

2.6

4

Timer stroke with S/T OFF

mm

1.9

1.4

2.4

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T ON

mm

6.6

5.9

7.3

Timer stroke with S/T OFF

mm

5.5

5.1

5.9

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T OFF

mm

6.8

6.2

7.4

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T OFF

mm

9.4

8.6

10.2

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T OFF

mm

9.8

9.3

10.2

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.01

5.91

6.11

MS dimension

mm

0.6

0.5

0.7

BCS stroke

mm

5.5

5.3

5.7

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

42

37

47

Test data Ex:

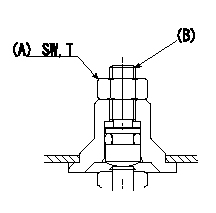

0000001601 BOOST COMPENSATOR ADJUSTMENT

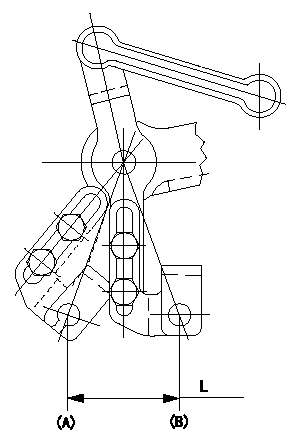

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=600r/min N2=750r/min P1=31.3kPa(235mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=600r/min N2=750r/min P1=31.3kPa(235mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

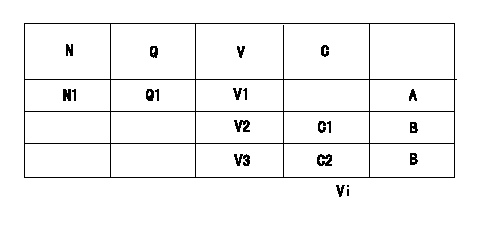

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Dummy bolt method

1. Hold the dummy bolt against the control lever at position N = N1 and Q = Q1 and fix using the lock nut.

2. At potentiometer adjustment, with the control lever contacting the dummy bolt, adjust the potentiometer so that the output voltage is V1.

3. After adjustment, remove the dummy bolt and confirm that the potentiometer output voltage at the control lever's idling and full speed positions is as specified above.

N:Pump speed

Q:Injection quantity

V:Output voltage

A:Adjusting point

B:Checking point

C:Position of the control lever

C1:Idling

C2:Full speed

Vi:Applied voltage

----------

N1=750r/min Q1=36.4+-1mm3/st V1=5.24+-0.03V

----------

N1=750r/min V1=5.24+-0.03V V2=2.16+-0.52V V3=9.02+-0.76V Q1=36.4+-1mm3/st Vi=10V

----------

N1=750r/min Q1=36.4+-1mm3/st V1=5.24+-0.03V

----------

N1=750r/min V1=5.24+-0.03V V2=2.16+-0.52V V3=9.02+-0.76V Q1=36.4+-1mm3/st Vi=10V

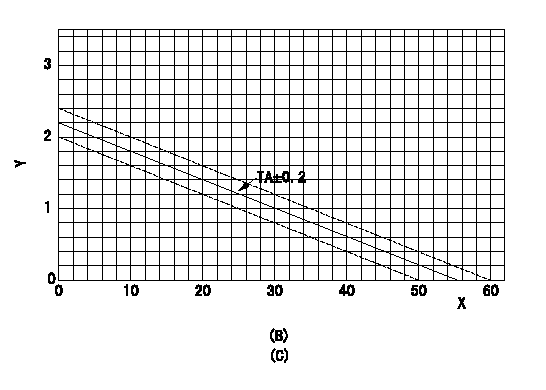

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjustment of the timer advance angle

Determine the timers stroke value from the graph and then adjust using the adjusting bolt.

(B) Timer stroke graph

(C) Graph TA = -0.04t+2.2 (0<= t deg C)

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

----------

----------

----------

----------

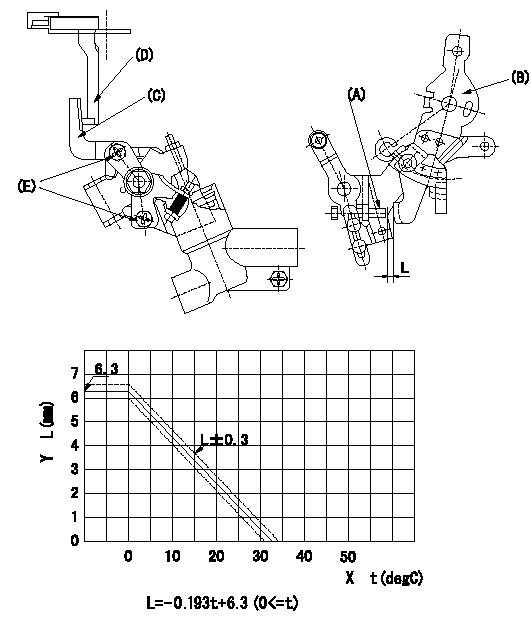

0000002001 W-FICD LEVER ADJUSTMENT

W-FICD adjustment

(1)Insert a block gauge L1 determined from the graph between the control lever (B) and the idling set screw (A).

(2)Fix bolt (E) in the position where W-FICD lever (C) contacts the control lever (D). (Tighten to torque T.)

(3)Remove the block gauge and shims after completing adjustment.

Caution: The temperature of the wax at adjustment must not exceed a.

Y = control lever dimension L (control lever position)

X = temperature t (deg C)

----------

L1=L+-0.3mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=35degC

----------

----------

L1=L+-0.3mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=35degC

----------

0000002101 ACCELERATOR LINK STROKE

Adjustment of the accelerator link stroke

As shown in the figure, adjust so that the accelerator link's stroke between idle (B) and full speed (A) is L1.

(A): Full-speed

(B): Idle

----------

L=32.9+-1mm

----------

L=32.9+-1mm

----------

L=32.9+-1mm

----------

L=32.9+-1mm

Information:

Personal injury can result from improper handling of chemicals.Make sure you use all the necessary protective equipment required to do the job.Make sure that you read and understand all directions and hazards described on the labels and material safety data sheet of any chemical that is used.Observe all safety precautions recommended by the chemical manufacturer for handling, storage, and disposal of chemicals.

Before servicing/performing maintenance on the machine, electrical power must be physically disconnected; battery plugs must be disconnected from the batteries, or the trailing cable must be unplugged, and warning tags and padlocks shall be applied by a certified electrician. Certified electricians shall perform or direct any electrical work, including any energized testing, repair work in controllers, motors, or other approved compartments, and shall insure that all compartments are properly closed and inspected prior to re-energization. All applicable lock out and tag out procedures must be followed.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

Connector Pin Arcing

Injector solenoid diagnostic codes can be a result of poor electrical connections between the injector and injector harness. When troubleshooting a suspected injector failure, carefully inspect injector connector pins for signs of arcing. If arcing is observed, both injector and harness must be replaced due to damaged connector pins and sockets. Connector pin arcing can also be caused by improper removal the harness from the injector. When removing the harness use approved tool 458-3562 Tool As. Refer to Illustration 2.

Illustration 2 g06300012

Connector Pin Arcing

Illustration 3 g06399136

(1) Correct placement of tool

Illustration 4 g06399157

(2) Correct removal of connectorRefer to the following publications for more details and specifications:

Refer to Troubleshooting, RENR9343, "Injector Solenoid - Test".

Refer to Service Magazine, SEPD1840, "A New Improved Removal and Installation of the Injector Harness Procedure is Now Used on Certain C13, C15, and C18 Engines".

Refer to Engine News, SEBD9957, "A New Improved Removal and Installation of the Injector Harness Procedure is Now Used on Certain C13, C15, and C18 Engines".Fuel System Restrictions

Adequate fuel flow rate through the engine is required to cool fuel injectors and injector solenoids. Contaminated fuel combined with inadequate maintenance of the secondary fuel filter can reduce fuel flow rate. Fuel filter restrictions can cause fuel to bypass internally within the secondary filter base. This bypass will allow fuel flow to return to tank without cooling the fuel injectors. Refer to Illustration 5.

Illustration 5 g06399162

(3) Normal Solenoid

(4) Overheated SolenoidTroubleshooting of injector failures should include investigation of secondary filter internal bypass. Internal bypass can be indicated by measuring fuel pressure at the sample port that is on the secondary filter base. Fuel bypass will occur as pressure approaches 655 kPa (95 psi) at the sample port. High-pressure measurements with the engine operating at low idle are especially concerning.Pressure measurement at the sample port differs from the measurement of pressure near the engine cylinder head. Pressure measured at the sample port is immediately upstream of the fuel filter element and the