Information injection-pump assembly

BOSCH

9 460 612 765

9460612765

ZEXEL

104741-3312

1047413312

MITSUBISHI

ME201514

me201514

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-3312 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104641-3312 |

| 3. | NUMBER PLATE | 146957-0200 |

| 4. | _ | 479771-0520 |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1301 |

| 8. | Nozzle and Holder | ME200204 |

| 9. | Open Pre:MPa(Kqf/cm2) | 14.7{150} |

| 10. | NOZZLE-HOLDER | 105078-0181 |

| 11. | NOZZLE | 105007-1290 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0220 | SUPPLY PUMP |

| 9. | [1] | 146103-0100 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-3520 | ROLLER SET |

| 24. | [1] | 146303-0000 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-3220 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146311-8520 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 34. | [1] | 146312-5000 | COMPRESSION SPRING |

| 34B. | [1] | 146312-5100 | COMPRESSION SPRING |

| 34C. | [1] | 146312-5200 | COMPRESSION SPRING |

| 35/1. | [1] | 146690-3200 | SHIM D11.5&9.4T0.1 |

| 35/1. | [1] | 146690-3300 | SHIM D11.5&9.4T0.2 |

| 35/1. | [1] | 146690-3400 | SHIM D11.5&9.4T0.25 |

| 35/1. | [1] | 146690-3500 | SHIM D11.5&9.4T1.0 |

| 35/1. | [1] | 146690-4100 | SHIM D11.5&9.4T2 |

| 35/1. | [1] | 146690-4200 | SHIM D11.5&9.4T0.5 |

| 35/1. | [1] | 146690-4300 | SHIM D11.5&9.4T0.75 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-4020 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-5100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 41. | [1] | 146312-2000 | COMPRESSION SPRING |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0000 | SHIM D17.0&5.2T0.50 |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146603-0500 | SHIM D17.0&5.2T1.80 |

| 48/1. | [1] | 146603-0600 | SHIM D17.0&5.2T2.00 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 48/1. | [1] | 146690-1900 | SHIM D17&5.2T1.7 |

| 48/1. | [1] | 146690-5800 | SHIM |

| 48/1. | [1] | 146690-5900 | SHIM |

| 48/1. | [1] | 146690-6000 | SHIM |

| 48/1. | [1] | 146690-6100 | SHIM |

| 48/1. | [1] | 146690-6200 | SHIM |

| 48/1. | [1] | 146690-6300 | SHIM |

| 48/1. | [1] | 146690-6400 | SHIM |

| 48/1. | [1] | 146690-6500 | SHIM |

| 48/1. | [1] | 146690-6600 | SHIM |

| 48/1. | [1] | 146690-6700 | SHIM |

| 48/1. | [1] | 146690-6800 | SHIM |

| 48/1. | [1] | 146690-6900 | SHIM |

| 48/1. | [1] | 146690-7000 | SHIM |

| 48/1. | [1] | 146690-7100 | SHIM |

| 48/1. | [1] | 146690-7200 | SHIM |

| 48/1. | [1] | 146690-7300 | SHIM |

| 48/1. | [1] | 146690-7400 | SHIM |

| 48/1. | [1] | 146690-7500 | SHIM |

| 48/1. | [1] | 146690-7800 | SHIM |

| 49. | [2] | 146234-0600 | GUIDE PIN |

| 50. | [1] | 146403-4920 | HYDRAULIC HEAD |

| 50. | [1] | 146403-4920 | HYDRAULIC HEAD |

| 50. | [1] | 146403-4920 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0000 | SHIM D9.5&3.0T1.90 |

| 52/1. | [1] | 146420-0100 | SHIM D9.5&3.0T1.92 |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0300 | SHIM D9.5&3.0T1.96 |

| 52/1. | [1] | 146420-0400 | SHIM D9.5&3.0T1.98 |

| 52/1. | [1] | 146420-0500 | SHIM D9.5&3.0T2.00 |

| 52/1. | [1] | 146420-0600 | SHIM D9.5&3.0T2.02 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-0800 | SHIM D9.5&3.0T2.06 |

| 52/1. | [1] | 146420-0900 | SHIM D9.5&3.0T2.08 |

| 52/1. | [1] | 146420-1000 | SHIM D9.5&3.0T2.10 |

| 52/1. | [1] | 146420-1100 | SHIM D9.5&3.0T2.12 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1300 | SHIM D9.5&3.0T2.16 |

| 52/1. | [1] | 146420-1400 | SHIM D9.5&3.0T2.18 |

| 52/1. | [1] | 146420-1500 | SHIM D9.5&3.0T2.20 |

| 52/1. | [1] | 146420-1600 | SHIM D9.5&3.0T2.22 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-1800 | SHIM D9.5&3.0T2.26 |

| 52/1. | [1] | 146420-1900 | SHIM D9.5&3.0T2.28 |

| 52/1. | [1] | 146420-2000 | SHIM D9.5&3.0T2.30 |

| 52/1. | [1] | 146420-2100 | SHIM D9.5&3.0T2.32 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2300 | SHIM D9.5&3.0T2.36 |

| 52/1. | [1] | 146420-2400 | SHIM D9.5&3.0T2.38 |

| 52/1. | [1] | 146420-2500 | SHIM D9.5&3.0T2.40 |

| 52/1. | [1] | 146420-2600 | SHIM D9.5&3.0T2.42 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-2800 | SHIM D9.5&3.0T2.46 |

| 52/1. | [1] | 146420-2900 | SHIM D9.5&3.0T2.48 |

| 52/1. | [1] | 146420-3000 | SHIM D9.5&3.0T2.50 |

| 52/1. | [1] | 146420-3100 | SHIM D9.5&3.0T2.52 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3300 | SHIM D9.5&3.0T2.56 |

| 52/1. | [1] | 146420-3400 | SHIM D9.5&3.0T2.58 |

| 52/1. | [1] | 146420-3500 | SHIM D9.5&3.0T2.60 |

| 52/1. | [1] | 146420-3600 | SHIM D9.5&3.0T2.62 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-3800 | SHIM D9.5&3.0T2.66 |

| 52/1. | [1] | 146420-3900 | SHIM D9.5&3.0T2.68 |

| 52/1. | [1] | 146420-4000 | SHIM D9.5&3.0T2.70 |

| 52/1. | [1] | 146420-4100 | SHIM D9.5&3.0T2.72 |

| 52/1. | [1] | 146420-4200 | SHIM D9.5&3.0T2.74 |

| 52/1. | [1] | 146420-4300 | SHIM D9.5&3.0T2.76 |

| 52/1. | [1] | 146420-4400 | SHIM D9.5&3.0T2.78 |

| 52/1. | [1] | 146420-4500 | SHIM D9.5&3.0T2.80 |

| 52/1. | [1] | 146420-4600 | SHIM D9.5&3.0T2.82 |

| 52/1. | [1] | 146420-4700 | SHIM D9.5&3.0T2.84 |

| 52/1. | [1] | 146420-4800 | SHIM D9.5&3.0T2.86 |

| 52/1. | [1] | 146420-4900 | SHIM D9.5&3.0T2.88 |

| 52/1. | [1] | 146420-5000 | SHIM D9.5&3.0T2.90 |

| 52/1. | [1] | 146420-5100 | SHIM D9.5&3.0T1.74 |

| 52/1. | [1] | 146420-5200 | SHIM D9.5&3.0T1.76 |

| 52/1. | [1] | 146420-5300 | SHIM D9.5&3.0T1.78 |

| 52/1. | [1] | 146420-5400 | SHIM D9.5&3.0T1.80 |

| 52/1. | [1] | 146420-5500 | SHIM D9.5&3.0T1.82 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 52/1. | [1] | 146420-5700 | SHIM D9.5&3.0T1.86 |

| 52/1. | [1] | 146420-5800 | SHIM D9.5&3.0T1.88 |

| 54. | [4] | 146433-0100 | GASKET D12&6.4T1.00 |

| 55. | [4] | 146430-4820 | DELIVERY-VALVE ASSEMBLY |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0720 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 66. | [1] | 146600-0100 | O-RING |

| 67. | [1] | 146703-5120 | COMPENSATOR,MANIFOLD-PRES |

| 67/1. | [1] | 146805-8220 | GOVERNOR COVER |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/16. | [1] | 146526-3000 | BLEEDER SCREW |

| 67/23. | [1] | 146925-7520 | BRACKET |

| 67/24. | [2] | 010206-2240 | HEX-SOCKET-HEAD CAP SCREW |

| 67/31. | [1] | 146710-0700 | BUSHING |

| 67/32. | [1] | 146711-0000 | PLATE |

| 67/33. | [1] | 139218-0400 | UNION NUT |

| 67/34. | [1] | 146712-0700 | BEARING PIN |

| 67/35. | [1] | 146621-0300 | UNION NUT |

| 67/36. | [1] | 146600-1400 | O-RING |

| 67/37. | [1] | 146710-0100 | BUSHING |

| 67/38. | [1] | 139506-0200 | GASKET D8.9&6.8T1.00 |

| 67/39. | [1] | 146620-0300 | CAPSULE |

| 67/40. | [1] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 67/41. | [1] | 146713-4300 | ADJUSTING PIN |

| 67/42. | [2] | 146714-0200 | PLATE |

| 67/43. | [1] | 146715-0300 | DIAPHRAGM |

| 67/44. | [1] | 139306-0100 | LOCKING WASHER |

| 67/45. | [1] | 013030-6040 | UNION NUT M6P1H3.6 |

| 67/46. | [1] | 146716-0000 | UNION NUT |

| 67/47. | [1] | 146717-2900 | COILED SPRING |

| 67/48/1. | [1] | 146720-3000 | SPACER BUSHING L3.7 |

| 67/48/1. | [1] | 146720-3100 | SPACER BUSHING L3.9 |

| 67/48/1. | [1] | 146720-3200 | SPACER BUSHING L4.1 |

| 67/48/1. | [1] | 146720-3300 | SPACER BUSHING L4.3 |

| 67/48/1. | [1] | 146720-3400 | SPACER BUSHING L4.5 |

| 67/48/1. | [1] | 146720-3500 | SPACER BUSHING L4.7 |

| 67/48/1. | [1] | 146720-3600 | SPACER BUSHING L4.9 |

| 67/48/1. | [1] | 146720-3700 | SPACER BUSHING L5.1 |

| 67/48/1. | [1] | 146720-3800 | SPACER BUSHING L5.3 |

| 67/48/1. | [1] | 146720-3900 | SPACER BUSHING L5.5 |

| 67/48/1. | [1] | 146720-4000 | SPACER BUSHING L5.7 |

| 67/48/1. | [1] | 146720-4100 | SPACER BUSHING L5.9 |

| 67/48/1. | [1] | 146720-4200 | SPACER BUSHING L6.1 |

| 67/48/1. | [1] | 146720-4300 | SPACER BUSHING L6.3 |

| 67/48/1. | [1] | 146720-4400 | SPACER BUSHING L6.5 |

| 67/48/1. | [1] | 146720-8900 | SPACER BUSHING L6.7 |

| 67/48/1. | [1] | 146720-9000 | SPACER BUSHING L6.9 |

| 67/48/1. | [1] | 146720-9100 | SPACER BUSHING L7.1 |

| 67/48/1. | [1] | 146720-9200 | SPACER BUSHING L7.3 |

| 67/48/1. | [1] | 146720-9300 | SPACER BUSHING L7.5 |

| 67/48/1. | [1] | 146720-9400 | SPACER BUSHING L7.7 |

| 67/48/1. | [1] | 146720-9500 | SPACER BUSHING L7.9 |

| 67/48/1. | [1] | 146720-9600 | SPACER BUSHING L8.1 |

| 67/48/1. | [1] | 146720-9700 | SPACER BUSHING L8.3 |

| 67/48/1. | [1] | 146720-9800 | SPACER BUSHING L8.5 |

| 67/48/1. | [1] | 146720-9900 | SPACER BUSHING L3.6 |

| 67/48/1. | [1] | 146725-0000 | SPACER BUSHING L3.8 |

| 67/48/1. | [1] | 146725-0100 | SPACER BUSHING L4.0 |

| 67/48/1. | [1] | 146725-0200 | SPACER BUSHING L4.2 |

| 67/48/1. | [1] | 146725-0300 | SPACER BUSHING L4.4 |

| 67/48/1. | [1] | 146725-0400 | SPACER BUSHING L4.6 |

| 67/48/1. | [1] | 146725-0500 | SPACER BUSHING L4.8 |

| 67/48/1. | [1] | 146725-0600 | SPACER BUSHING L5.0 |

| 67/48/1. | [1] | 146725-0700 | SPACER BUSHING L5.2 |

| 67/48/1. | [1] | 146725-0800 | SPACER BUSHING L5.4 |

| 67/48/1. | [1] | 146725-0900 | SPACER BUSHING L5.6 |

| 67/48/1. | [1] | 146725-1000 | SPACER BUSHING L5.8 |

| 67/48/1. | [1] | 146725-1100 | SPACER BUSHING L6.0 |

| 67/48/1. | [1] | 146725-1200 | SPACER BUSHING L6.2 |

| 67/48/1. | [1] | 146725-1300 | SPACER BUSHING L6.4 |

| 67/48/1. | [1] | 146725-1400 | SPACER BUSHING L6.6 |

| 67/48/1. | [1] | 146725-1500 | SPACER BUSHING L6.8 |

| 67/48/1. | [1] | 146725-1600 | SPACER BUSHING L7.0 |

| 67/48/1. | [1] | 146725-1700 | SPACER BUSHING L7.2 |

| 67/48/1. | [1] | 146725-1800 | SPACER BUSHING L7.4 |

| 67/48/1. | [1] | 146725-1900 | SPACER BUSHING L7.6 |

| 67/48/1. | [1] | 146725-2000 | SPACER BUSHING L7.8 |

| 67/48/1. | [1] | 146725-2100 | SPACER BUSHING L8.0 |

| 67/48/1. | [1] | 146725-2200 | SPACER BUSHING L8.2 |

| 67/48/1. | [1] | 146725-2300 | SPACER BUSHING L8.4 |

| 67/48/1. | [1] | 146725-2400 | SPACER BUSHING L8.6 |

| 67/49. | [1] | 146721-3621 | COVER |

| 67/50. | [1] | 146722-0200 | FLAT-HEAD SCREW |

| 67/51. | [1] | 146600-0300 | O-RING |

| 67/53. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 67/54. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/54. | [2] | 139006-4600 | BLEEDER SCREW |

| 67/55. | [2] | 139006-4800 | BLEEDER SCREW |

| 67/56. | [1] | 146723-0300 | CONTROL LEVER |

| 67/57. | [1] | 146712-0100 | BEARING PIN |

| 67/58. | [2] | 146620-0600 | CAPSULE |

| 67/59. | [2] | 026506-1040 | GASKET D9.9&6.2T1 |

| 67/60. | [1] | 146724-0300 | ELEMENT |

| 67/61. | [1] | 146724-0600 | CAPSULE |

| 67/64. | [1] | 146930-8900 | BRACKET |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/96. | [1] | 146932-1620 | BRACKET |

| 67/98. | [2] | 146648-2800 | SPACER BUSHING |

| 67/102. | [1] | 146930-9000 | BRACKET |

| 67/112. | [1] | 146930-9100 | BRACKET |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 68. | [1] | 146514-6220 | CONTROL SHAFT |

| 69. | [1] | 139310-0200 | PLAIN WASHER |

| 72. | [1] | 146830-8720 | CONTROL LEVER |

| 72B. | [1] | 146830-8820 | CONTROL LEVER |

| 73. | [1] | 014110-6440 | LOCKING WASHER |

| 75. | [1] | 013020-6040 | UNION NUT M6P1H5 |

| 95. | [1] | 146865-0720 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0100 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 110/1. | [1] | 146571-0500 | SHIM D20.2&8.3T1.15 |

| 110/1. | [1] | 146571-0600 | SHIM D20.2&8.3T1.35 |

| 110/1. | [1] | 146571-0700 | SHIM D20.2&8.3T1.55 |

| 110/1. | [1] | 146571-0800 | SHIM D20.2&8.3T1.75 |

| 111. | [1] | 146602-0600 | PLAIN WASHER D20&8.4T1.40 |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER D17&6.4T1.60 |

| 115. | [1] | 146975-2800 | SLIDING SLEEVE |

| 116. | [1] | 146576-0200 | CAP |

| 117/1. | [1] | 146577-1800 | PLUG L2.10 |

| 117/1. | [1] | 146577-1900 | PLUG L2.30 |

| 117/1. | [1] | 146577-2000 | PLUG L2.50 |

| 117/1. | [1] | 146577-2100 | PLUG L2.70 |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-3100 | PLUG L4.70 |

| 117/1. | [1] | 146577-3200 | PLUG L4.90 |

| 117/1. | [1] | 146577-3300 | PLUG L5.10 |

| 117/1. | [1] | 146577-6700 | PLUG L2.2 |

| 117/1. | [1] | 146577-6800 | PLUG L2.4 |

| 117/1. | [1] | 146577-6900 | PLUG L2.6 |

| 117/1. | [1] | 146577-7000 | PLUG L2.8 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 117/1. | [1] | 146577-7900 | PLUG L4.6 |

| 117/1. | [1] | 146577-8000 | PLUG L4.8 |

| 117/1. | [1] | 146577-8100 | PLUG L5.0 |

| 117/1. | [1] | 146877-0000 | PLUG L5.2 |

| 117/1. | [1] | 146877-0100 | PLUG L5.3 |

| 117/1. | [1] | 146877-0200 | PLUG L5.4 |

| 117/1. | [1] | 146877-0300 | PLUG L5.5 |

| 117/1. | [1] | 146877-4700 | PLUG |

| 117/1. | [1] | 146877-4800 | PLUG |

| 117/1. | [1] | 146877-4900 | PLUG |

| 117/1. | [1] | 146877-5000 | PLUG |

| 123. | [4] | 146620-0500 | HEX-SOCKET-HEAD CAP SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146650-7620 | PULLING ELECTROMAGNET |

| 137. | [2] | 139514-0200 | GASKET |

| 145. | [1] | 146621-1000 | UNION NUT |

| 147. | [1] | 146600-5000 | O-RING |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 217. | [1] | 146542-5300 | SLOTTED WASHER |

| 218. | [1] | 146592-2500 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2600 | COILED SPRING |

| 224. | [1] | 139006-4700 | BLEEDER SCREW |

| 230. | [1] | 146932-2120 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 233. | [1] | 146662-3720 | WIRE |

| 234. | [1] | 139006-4800 | BLEEDER SCREW |

| 235. | [1] | 146931-6100 | BRACKET |

| 236. | [1] | 139006-4700 | BLEEDER SCREW |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 244. | [1] | 146931-7220 | BRACKET |

| 245. | [3] | 139512-0500 | GASKET |

| 245. | [3] | 139512-0500 | GASKET |

| 246. | [1] | 139812-1900 | EYE BOLT |

| 247. | [1] | 146666-6820 | PIPE |

| 248. | [1] | 146614-0200 | SPACER BUSHING |

| 275. | [1] | 146612-7420 | BRACKET |

| 276. | [2] | 010010-2040 | BLEEDER SCREW M10P1.5L20 |

| 280. | [1] | 146361-2820 | START ADVANCE ASSY |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW M6P1L12 |

| 283. | [1] | 146679-3920 | ACTUATOR |

| 284. | [2] | 139005-0400 | BLEEDER SCREW |

| 286. | [1] | 139006-4600 | BLEEDER SCREW |

| 294. | [1] | 146666-7520 | INLET UNION |

| 310. | [1] | 146673-9922 | POTENTCIOMETER |

| 310/2. | [2] | 139104-0400 | FLAT-HEAD SCREW |

| 310/3. | [1] | 146648-2900 | JOINT CONNECTION |

| 310/3B. | [1] | 146648-3000 | JOINT CONNECTION |

| 310/3C. | [1] | 146648-3100 | JOINT CONNECTION |

| 310/3D. | [1] | 146648-3200 | JOINT CONNECTION |

| 310/3E. | [1] | 146648-3300 | JOINT CONNECTION |

| 310/3F. | [1] | 146648-4700 | JOINT CONNECTION |

| 310/3G. | [1] | 146648-5300 | JOINT CONNECTION |

| 310/3H. | [1] | 146649-1700 | JOINT CONNECTION |

| 310/4. | [1] | 146661-0601 | BOOT |

| 312. | [1] | 146932-0621 | BRACKET |

| 313. | [1] | 020106-1240 | BLEEDER SCREW M6P1.0L12 |

| 344. | [1] | 146666-7620 | INLET UNION |

| 800S. | [1] | 146018-5020 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0720 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146672-2820 | PULSE GENERATOR |

| 903/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 906. | [1] | 146957-0200 | NAMEPLATE |

| 910S. | [1] | 146600-4320 | PARTS SET |

| 911S. | [1] | 146672-2820 | PULSE GENERATOR |

| 911S/2. | [1] | 146600-1300 | O-RING &13W1.9 |

| 912S. | [1] | 026508-1140 | GASKET D11.4&8.2T1 |

| 913S. | [1] | 146422-0000 | BLEEDER SCREW |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 915S. | [1] | 146662-3720 | WIRE |

| 916S. | [1] | 025804-1610 | WOODRUFF KEY |

| 917S. | [1] | 146684-2310 | POTENTCIOMETER |

Include in #2:

104741-3312

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 612 765

9460612765

ZEXEL

104741-3312

1047413312

MITSUBISHI

ME201514

me201514

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

600

600

600

Boost pressure

kPa

31.3

30

32.6

Boost pressure

mmHg

235

225

245

Average injection quantity

mm3/st.

67.3

66.8

67.8

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

57.2

56.7

57.7

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

NA

NA

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

81.3

80.8

81.8

Difference in delivery

mm3/st.

6.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

600

600

600

Boost pressure

kPa

31.3

30

32.6

Boost pressure

mmHg

235

225

245

Average injection quantity

mm3/st.

67.3

66.3

68.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_05

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

57.2

56.2

58.2

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

81.3

80.3

82.3

Difference in delivery

mm3/st.

7

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_07

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

75.8

72.3

79.3

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.8

53.8

59.8

Difference in delivery

mm3/st.

17

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

3000

3000

3000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

12

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.8

51.8

61.8

Difference in delivery

mm3/st.

17.5

Basic

*

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.4

10.4

14.4

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12.4

9.9

14.9

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

110

90

130

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

110

90

130

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

400

400

400

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity with S/T ON

cm3/min

740

610

870

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T ON

kPa

500

461

539

Pressure with S/T ON

kgf/cm2

5.1

4.7

5.5

Pressure with S/T OFF

kPa

451

431

471

Pressure with S/T OFF

kgf/cm2

4.6

4.4

4.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

550

550

550

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T OFF

kPa

324

275

373

Pressure with S/T OFF

kgf/cm2

3.3

2.8

3.8

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

700

700

700

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T ON

kPa

422

373

471

Pressure with S/T ON

kgf/cm2

4.3

3.8

4.8

Pressure with S/T OFF

kPa

373

324

422

Pressure with S/T OFF

kgf/cm2

3.8

3.3

4.3

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T ON

kPa

500

451

549

Pressure with S/T ON

kgf/cm2

5.1

4.6

5.6

Pressure with S/T OFF

kPa

451

422

480

Pressure with S/T OFF

kgf/cm2

4.6

4.3

4.9

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_05

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T ON

kPa

559

510

608

Pressure with S/T ON

kgf/cm2

5.7

5.2

6.2

Pressure with S/T OFF

kPa

510

461

559

Pressure with S/T OFF

kgf/cm2

5.2

4.7

5.7

Oil temperature

degC

50

48

52

Stop lever angle_06

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure with S/T OFF

kPa

667

618

716

Pressure with S/T OFF

kgf/cm2

6.8

6.3

7.3

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T ON

mm

5.2

4.7

5.7

Timer stroke with S/T OFF

mm

4

3.8

4.2

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

700

700

700

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T ON

mm

3.3

2.6

4

Timer stroke with S/T OFF

mm

1.9

1.1

2.7

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T ON

mm

5.2

4.5

5.9

Timer stroke with S/T OFF

mm

4

3.6

4.4

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T OFF

mm

5.5

4.9

6.1

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke with S/T OFF

mm

9.8

9.3

10.2

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

6.01

5.91

6.11

MS dimension

mm

0.7

0.6

0.8

BCS stroke

mm

5.5

5.3

5.7

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

39

34

44

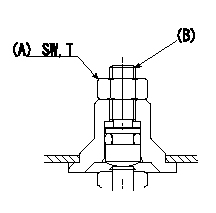

Test data Ex:

0000001601 BOOST COMPENSATOR ADJUSTMENT

BCS adjustment procedure

1. At full boost pressure, set so that the full injection quantity is within the specifications (adjusting point).

2. Perform boost compensator intermediate operation point adjustment (pump speed N1, boost pressure P1).

3. When injection quantity at boost pressure P2 and pump speed N2 is not as specified, loosen nut (A) and adjust position of screw (B) so that injection quantity is as specified. The screw position should be within +-1 turn of initial position.

4. The nut tightening torque is T.

----------

N1=600r/min N2=750r/min P1=31.3kPa(235mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

----------

N1=600r/min N2=750r/min P1=31.3kPa(235mmHg) P2=0kPa(0mmHg) T=6~9N-m(0.6~0.9kgf-m)

----------

SW=10mm T=6~9N-m(0.6~0.9kgf-m)

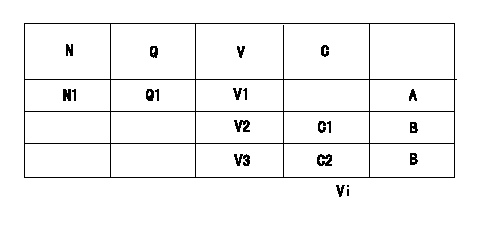

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Dummy bolt method

1. Hold the dummy bolt against the control lever at position N = N1 and Q = Q1 and fix using the lock nut.

2. At potentiometer adjustment, with the control lever contacting the dummy bolt, adjust the potentiometer so that the output voltage is V1.

3. After adjustment, remove the dummy bolt and confirm that the potentiometer output voltage at the control lever's idling and full speed positions is as specified above.

N:Pump speed

Q:Injection quantity

V:Output voltage

A:Adjusting point

B:Checking point

C:Position of the control lever

C1:Idling

C2:Full speed

Vi:Applied voltage

----------

N1=750r/min Q1=36.4+-1mm3/st V1=5.35+-0.03V

----------

N1=750r/min V1=5.35+-0.03V V2=1.94+-0.52V V3=8.58+-0.76V Q1=36.4+-1.0mm3/st Vi=10V

----------

N1=750r/min Q1=36.4+-1mm3/st V1=5.35+-0.03V

----------

N1=750r/min V1=5.35+-0.03V V2=1.94+-0.52V V3=8.58+-0.76V Q1=36.4+-1.0mm3/st Vi=10V

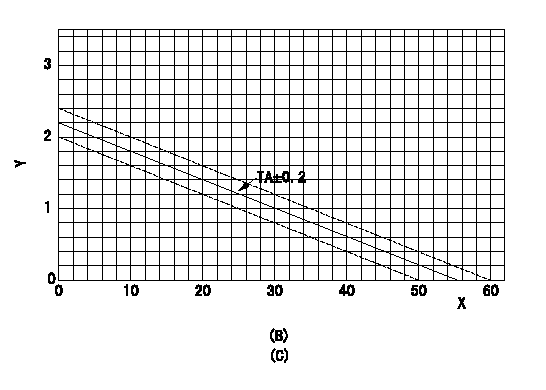

0000001901 W-CSD ADJUSTMENT

Adjustment of the W-CSD

Adjustment of the timer advance angle

Determine the timers stroke value from the graph and then adjust using the adjusting bolt.

(B) Timer stroke graph

(C) Graph TA = -0.04t+2.2 (0<= t deg C)

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

----------

----------

----------

----------

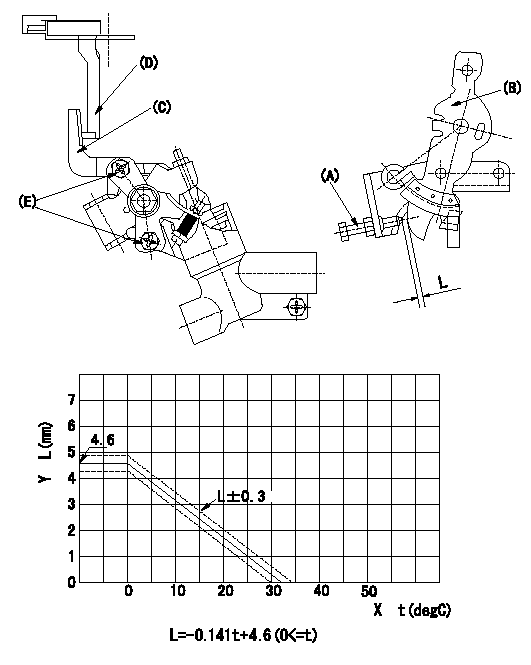

0000002001 W-FICD LEVER ADJUSTMENT

W-FICD adjustment

(1)Insert a block gauge L1 determined from the graph between the control lever (B) and the idling set screw (A).

(2)Fix bolt (E) in the position where W-FICD lever (C) contacts the control lever (D). (Tighten to torque T.)

(3)Remove the block gauge and shims after completing adjustment.

Caution: The temperature of the wax at adjustment must not exceed a.

Y = control lever dimension L (control lever position)

X = temperature t (deg C)

----------

L1=L+-0.3mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=35degC

----------

----------

L1=L+-0.3mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=35degC

----------

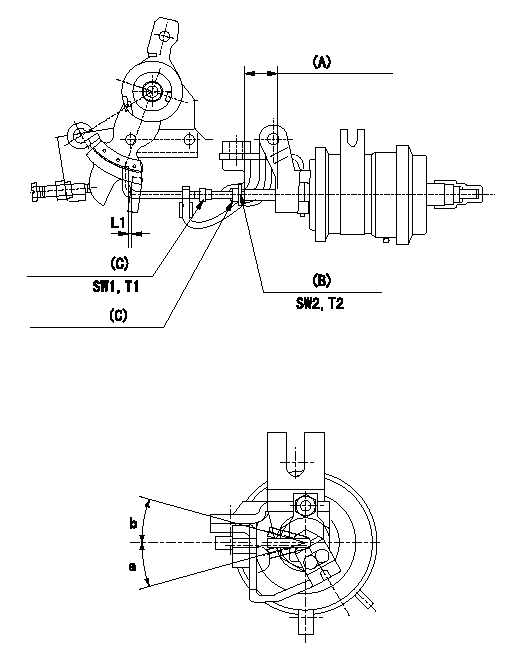

0000002101 V-FICD ADJUSTMENT

Adjustment of the two stage actuator (FICD).

(1)Attach the 2-stage actuator to the injection pump.

(2)Position the control lever in the idling position.

(3)Adjust using nut (C) so that the clearance between the control lever and the rod is L1.

(4)Actuator stroke adjustment is not necessary.

(5)Allowable angle when adjusting the rod position: c

(A): Actuator stroke

(B): Stroke adjusting nut

(C): Rod position adjusting nut

----------

L1=1+1mm c=+-20deg

----------

L1=1+1mm SW1=SW7 SW2=SW8 T1=1.4~2.0N-m(0.14~0.2kgf-m) T2=3.4~4.9N-m(0.35~0.5kgf-m) a=20deg b=20deg

----------

L1=1+1mm c=+-20deg

----------

L1=1+1mm SW1=SW7 SW2=SW8 T1=1.4~2.0N-m(0.14~0.2kgf-m) T2=3.4~4.9N-m(0.35~0.5kgf-m) a=20deg b=20deg

Information:

Literature Information

This manual should be stored in the operator's compartment in the literature holder or seat back literature storage area.This manual contains safety information, operation instructions, and maintenance recommendations.Some photographs or illustrations in this publication show details or attachments that can be different from your machine.Continuing improvement and advancement of product design might have caused changes to your machine which are not included in this publication. Read, study and keep this manual with the machine.Whenever a question arises regarding your machine, or this publication, please consult your Cat dealer for the latest available information.Safety

The safety section lists basic safety precautions. In addition, this section identifies the text and locations of warning signs and labels used on the machine.Operation

The operation section is a reference for the new operator and a refresher for the experienced operator. This section includes a discussion of gauges, switches, machine controls, attachment controls, and programming information.Photographs and illustrations guide the operator through correct procedures of checking, starting, operating and stopping the machine.Operating techniques outlined in this publication are basic. Skill and techniques develop as the operator gains knowledge of the machine and its capabilities.Maintenance

The maintenance section is a guide to equipment care.California Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.Battery posts, terminals and related accessories contain lead and lead compounds.Wash hands after handlingCertified Engine Maintenance

Proper maintenance and repair is essential to keep the engine and machine systems operating correctly. As the heavy duty off-road diesel engine owner, you are responsible for the performance of the required maintenance listed in the Owner's Manual, Operation and Maintenance Manual, and Service Manual.It is prohibited for any person engaged in the business of repairing, servicing, selling, leasing, or trading engines or machines to remove, alter, or render inoperative any emission related device or element of design installed on or in an engine or machine that is in compliance with the regulations (40 CFR Part 89). Certain elements of the machine and engine such as the exhaust system, fuel system, electrical system, intake air system and cooling system may be emission related and should not be altered unless approved by Caterpillar.Cat Product Identification Number

Effective First Quarter 2001 the Cat Product Identification Number (PIN) will change from 8 to 17 characters. In an effort to provide uniform equipment identification, Caterpillar and other construction equipment manufacturers are moving to comply with the latest version of the product identification numbering standard. Non-road machine PINs are defined by ISO 10261. The new PIN format will apply to all Cat machines and generator sets. The PIN plates and frame marking will display the 17 character PIN. The new format will look like the following:

Illustration 1 g00751314Where:1. Caterpillar's World Manufacturing Code (characters 1-3)2. Machine Descriptor (characters 4-8)3. Check Character (character 9)4. Machine Indicator Section (MIS) or Product Sequence Number (characters 10-17). These were previously referred to as the Serial Number.Machines and generator sets produced before First Quarter 2001 will

This manual should be stored in the operator's compartment in the literature holder or seat back literature storage area.This manual contains safety information, operation instructions, and maintenance recommendations.Some photographs or illustrations in this publication show details or attachments that can be different from your machine.Continuing improvement and advancement of product design might have caused changes to your machine which are not included in this publication. Read, study and keep this manual with the machine.Whenever a question arises regarding your machine, or this publication, please consult your Cat dealer for the latest available information.Safety

The safety section lists basic safety precautions. In addition, this section identifies the text and locations of warning signs and labels used on the machine.Operation

The operation section is a reference for the new operator and a refresher for the experienced operator. This section includes a discussion of gauges, switches, machine controls, attachment controls, and programming information.Photographs and illustrations guide the operator through correct procedures of checking, starting, operating and stopping the machine.Operating techniques outlined in this publication are basic. Skill and techniques develop as the operator gains knowledge of the machine and its capabilities.Maintenance

The maintenance section is a guide to equipment care.California Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.Battery posts, terminals and related accessories contain lead and lead compounds.Wash hands after handlingCertified Engine Maintenance

Proper maintenance and repair is essential to keep the engine and machine systems operating correctly. As the heavy duty off-road diesel engine owner, you are responsible for the performance of the required maintenance listed in the Owner's Manual, Operation and Maintenance Manual, and Service Manual.It is prohibited for any person engaged in the business of repairing, servicing, selling, leasing, or trading engines or machines to remove, alter, or render inoperative any emission related device or element of design installed on or in an engine or machine that is in compliance with the regulations (40 CFR Part 89). Certain elements of the machine and engine such as the exhaust system, fuel system, electrical system, intake air system and cooling system may be emission related and should not be altered unless approved by Caterpillar.Cat Product Identification Number

Effective First Quarter 2001 the Cat Product Identification Number (PIN) will change from 8 to 17 characters. In an effort to provide uniform equipment identification, Caterpillar and other construction equipment manufacturers are moving to comply with the latest version of the product identification numbering standard. Non-road machine PINs are defined by ISO 10261. The new PIN format will apply to all Cat machines and generator sets. The PIN plates and frame marking will display the 17 character PIN. The new format will look like the following:

Illustration 1 g00751314Where:1. Caterpillar's World Manufacturing Code (characters 1-3)2. Machine Descriptor (characters 4-8)3. Check Character (character 9)4. Machine Indicator Section (MIS) or Product Sequence Number (characters 10-17). These were previously referred to as the Serial Number.Machines and generator sets produced before First Quarter 2001 will