Information injection-pump assembly

ZEXEL

104741-1960

1047411960

ISUZU

8943139400

8943139400

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104741-1960 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105118-4602 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 18.1(185) |

| 10. | NOZZLE-HOLDER | 105048-3230 |

| 11. | NOZZLE |

Include in #2:

104741-1960

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104741-1960

1047411960

ISUZU

8943139400

8943139400

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

42.3

41.8

42.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

44.7

44.7

44.7

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

36.5

36.5

36.5

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

42.3

41.3

43.3

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

44.1

44.1

44.1

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2250

2250

2250

Average injection quantity

mm3/st.

12.5

9.5

15.5

Difference in delivery

mm3/st.

4

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2250

2250

2250

Average injection quantity

mm3/st.

12.5

9.5

15.5

Difference in delivery

mm3/st.

4

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

75

115

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

115

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Overflow quantity with S/T OFF

cm3/min

540

410

670

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

441

421

461

Pressure with S/T OFF

kgf/cm2

4.5

4.3

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1500

1500

1500

Pressure with S/T OFF

kPa

392

392

392

Pressure with S/T OFF

kgf/cm2

4

4

4

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

441

421

461

Pressure with S/T OFF

kgf/cm2

4.5

4.3

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1800

1800

1800

Pressure with S/T OFF

kPa

539

539

539

Pressure with S/T OFF

kgf/cm2

5.5

5.5

5.5

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

2.2

2

2.4

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1500

1500

1500

Timer stroke with S/T OFF

mm

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

2.2

2

2.4

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1800

1800

1800

Timer stroke with S/T OFF

mm

7

6.7

7.4

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1

0.9

1.1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

31

26

36

Test data Ex:

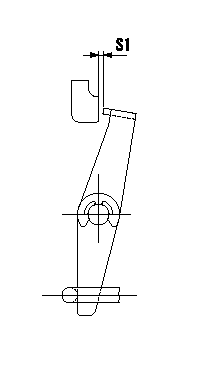

0000001801 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.The actuator and pump groups of these fuel injectors are sensitive to debris in the oil. The injector may malfunction due to debris in the oil, causing seizure, or high leaks in components.

Table 1

Revision Table

Revision Summary of Changes

3 Added serial numbers. Improvement Procedure

Clean oil rail after pump failure.Reference: Refer to Special Instruction, REHS3819 for the procedure to clean the oil rail after engine failure to avoid debris in the oil system.

Use clean oil and clean filters.The life of the injector depends on the oil quality. It can be increased if good cleaning practices are performed before installing the injectors.Reference: Refer to Operation and Maintenance Manual, SEBU6250 and Operation and Maintenance Manual, SEBU6251 for direction on oil sampling intervals and optimizing engine oil life.

Illustration 1 g06207717

(1) Actuator

(2) Pump Group

(3) Valve Seat Damage Due to Debris in the Oil SystemInjector Failure Due To Damage From Debris In The Oil May Not Be A Warrantable Failure

Illustration 2 g06244961

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.The actuator and pump groups of these fuel injectors are sensitive to debris in the oil. The injector may malfunction due to debris in the oil, causing seizure, or high leaks in components.

Table 1

Revision Table

Revision Summary of Changes

3 Added serial numbers. Improvement Procedure

Clean oil rail after pump failure.Reference: Refer to Special Instruction, REHS3819 for the procedure to clean the oil rail after engine failure to avoid debris in the oil system.

Use clean oil and clean filters.The life of the injector depends on the oil quality. It can be increased if good cleaning practices are performed before installing the injectors.Reference: Refer to Operation and Maintenance Manual, SEBU6250 and Operation and Maintenance Manual, SEBU6251 for direction on oil sampling intervals and optimizing engine oil life.

Illustration 1 g06207717

(1) Actuator

(2) Pump Group

(3) Valve Seat Damage Due to Debris in the Oil SystemInjector Failure Due To Damage From Debris In The Oil May Not Be A Warrantable Failure

Illustration 2 g06244961