Information injection-pump assembly

ZEXEL

104741-1490

1047411490

ISUZU

8944836290

8944836290

Rating:

Cross reference number

ZEXEL

104741-1490

1047411490

ISUZU

8944836290

8944836290

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

30.6

30.1

31.1

Difference in delivery

mm3/st.

3.5

Basic

*

Injection timing adjustment_02

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

21.4

17.9

24.9

Injection timing adjustment_03

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

31.6

28.9

34.3

Injection timing adjustment_04

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

30.6

29.6

31.6

Injection timing adjustment_05

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

31.9

29.4

34.4

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

28.1

24.6

31.6

Injection quantity adjustment

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

21.4

18.4

24.4

Difference in delivery

mm3/st.

4.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

1550

1550

1550

Average injection quantity

mm3/st.

0

0

0

Governor adjustment

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

6.2

4.2

8.2

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

6.2

4.2

8.2

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

70

60

80

Basic

*

Speed control lever angle

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

800

800

800

Overflow quantity

cm3/min

300

168

432

Stop lever angle

Pump speed

r/min

800

800

800

Pressure

kPa

264.5

245

284

Pressure

kgf/cm2

2.7

2.5

2.9

Basic

*

Stop lever angle_02

Pump speed

r/min

600

600

600

Pressure

kPa

196.5

167

226

Pressure

kgf/cm2

2

1.7

2.3

Stop lever angle_03

Pump speed

r/min

800

800

800

Pressure

kPa

264.5

245

284

Pressure

kgf/cm2

2.7

2.5

2.9

Stop lever angle_04

Pump speed

r/min

1400

1400

1400

Pressure

kPa

480.5

451

510

Pressure

kgf/cm2

4.9

4.6

5.2

0000001101

Pump speed

r/min

800

800

800

Timer stroke

mm

2

1.8

2.2

Basic

*

_02

Pump speed

r/min

800

800

800

Timer stroke

mm

2

1.7

2.3

_03

Pump speed

r/min

1400

1400

1400

Timer stroke

mm

6.2

5.8

6.6

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

2

1.9

2.1

Control lever angle alpha

deg.

20

16

24

Control lever angle beta

deg.

35

30

40

Test data Ex:

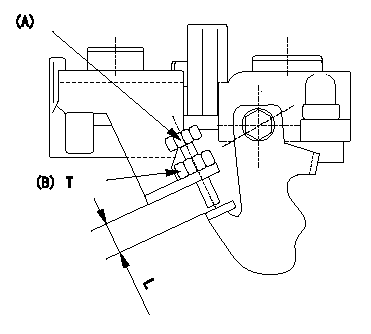

0000001801 STARTING I/Q ADJUSTMENT

Starting injection quantity adjustment

Adjust the adjusting bolt A so that the starting injection quantity adjustment is within the standards.

Fix using nut (B).

----------

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

----------

----------

L=7.4~11.1mm T=6~9N-m(0.6~0.9kgf-m)

Information:

Introduction

Diesel Particulate Filters (DPF) and Catalytic Converter Mufflers (CCM) are not applicable to all engines. Some engines contain a DPF and a CCM device that were installed as original equipment to meet engine emissions certification requirements. However, some engines may have had the devices installed during a retrofit program for emissions reduction.

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Procedure for Shipping the Diesel Particulate Filters (DPF)

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Place all the used Diesel Particulate Filter (DPF) center sections, regardless of condition, into a 0.152 mm (0.006 inch) thick plastic bag. Make sure that the bag is sealed before placing the DPF into a shipping container. This must be performed in order to contain any constituents from the used DPF during shipping. New replacement diesel particulate filters may come with a 0.152 mm (0.006 inch) plastic bag that can be used for wrapping the used DPF.Procedure for Shipping the Catalytic Converter Mufflers (CCM)

Seal the inlet port and the outlet port on all used Catalytic Converter Mufflers (CCM) with rubber caps or plastic caps. Various sized plastic caps can be ordered from the Cat Shop Supplies and Hand Tools catalog. Reference caps and plugs under the Shop Supplies section. An alternative is to seal the inlet ports and outlet ports with a 0.152 mm (0.006 inch) thick sheet of plastic and 50 mm (2 inch) wide sealing tape with good adhesive properties before shipping. Sealing or capping must be performed in order to contain any constituents from the used CCM during shipping.

Diesel Particulate Filters (DPF) and Catalytic Converter Mufflers (CCM) are not applicable to all engines. Some engines contain a DPF and a CCM device that were installed as original equipment to meet engine emissions certification requirements. However, some engines may have had the devices installed during a retrofit program for emissions reduction.

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Procedure for Shipping the Diesel Particulate Filters (DPF)

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Place all the used Diesel Particulate Filter (DPF) center sections, regardless of condition, into a 0.152 mm (0.006 inch) thick plastic bag. Make sure that the bag is sealed before placing the DPF into a shipping container. This must be performed in order to contain any constituents from the used DPF during shipping. New replacement diesel particulate filters may come with a 0.152 mm (0.006 inch) plastic bag that can be used for wrapping the used DPF.Procedure for Shipping the Catalytic Converter Mufflers (CCM)

Seal the inlet port and the outlet port on all used Catalytic Converter Mufflers (CCM) with rubber caps or plastic caps. Various sized plastic caps can be ordered from the Cat Shop Supplies and Hand Tools catalog. Reference caps and plugs under the Shop Supplies section. An alternative is to seal the inlet ports and outlet ports with a 0.152 mm (0.006 inch) thick sheet of plastic and 50 mm (2 inch) wide sealing tape with good adhesive properties before shipping. Sealing or capping must be performed in order to contain any constituents from the used CCM during shipping.