Information injection-pump assembly

ZEXEL

104741-1470

1047411470

ISUZU

8944528150

8944528150

Rating:

Cross reference number

ZEXEL

104741-1470

1047411470

ISUZU

8944528150

8944528150

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

47.5

47

48

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

40.6

37.1

44.1

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

36.5

34.5

38.5

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

41.7

40.7

42.7

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

43.2

43.2

43.2

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1900

1900

1900

Average injection quantity

mm3/st.

42.3

42.3

42.3

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

39.7

36.7

42.7

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

10.9

7.9

13.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

6

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

24.1

21.1

27.1

Difference in delivery

mm3/st.

3.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

75

115

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

80

60

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1600

1600

1600

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1600

1600

1600

Pressure

kPa

490

470

510

Pressure

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Pressure

kPa

608

579

637

Pressure

kgf/cm2

6.2

5.9

6.5

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Timer stroke with S/T OFF

mm

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1020

1020

1020

Timer stroke

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1600

1600

1600

Timer stroke

mm

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Timer stroke

mm

7.8

7.5

8.2

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001501

Pump speed

r/min

1150

1150

1150

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Average injection quantity

mm3/st.

39

39

39

Decrease qty

mm3/st.

8.5

7

10

Decrease rate

%

18

18

18

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1150

1150

1150

Height

m

0

0

0

Atmospheric pressure difference

kPa

0

0

0

Atmospheric pressure difference

mmHg

0

0

0

Decrease qty

mm3/st.

0

0

0

Decrease rate

%

0

0

0

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1150

1150

1150

Height

m

500

500

500

Atmospheric pressure difference

kPa

-5.9

-9.2

-2.6

Atmospheric pressure difference

mmHg

-44

-69

-19

Oil temperature

degC

50

48

52

Remarks

Point of inflection

Point of inflection

_04

Pump speed

r/min

1150

1150

1150

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Decrease qty

mm3/st.

-7.5

-7.5

-7.5

Decrease rate

%

-18

-21

-15

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

1

0.9

1.1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

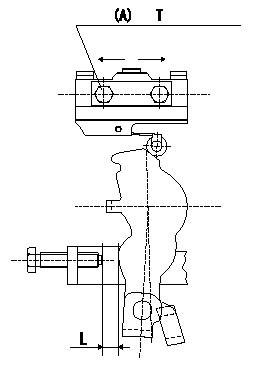

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1.Fix the control lever so that the distance between the control lever and the idling stopper bolt is L (control lever position: a).

2. In the above condition, adjust the installation position of the microswitch so that so that it turns OFF.

Must change from ON to OFF at L1. [Lever angle b (from idle).]

(A): microswitch fixing bolt

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

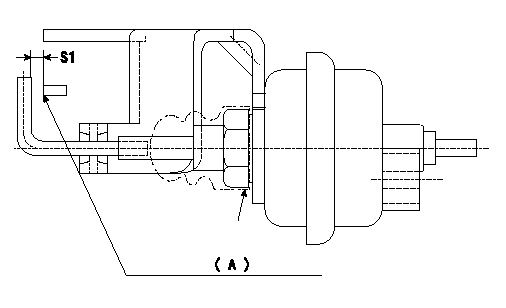

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 kPa {P2 mmHg} to the actuator and confirm that it moves through its full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

Information:

Install the pump cover onto the pump housing. Tighten the four middle bolts. Then, tighten the end bolts in a crisscross pattern. Tighten the bolts to a torque of 10.2 N m (90 lb in).Note: Make sure that the gasket is in place between the housing and the cover.

Repeat Step 1 and Step 2 in order to confirm the electrical connection for the pump coil was not damaged during the removal of the pump cover.

Install the oil inlet line adapter, inlet line, and harness connector to the pump.Note: After the HEUI pump is replaced or reassembled, the engine must be cranked for an extended length of time to fill the pump with oil.Note: Clear any diagnostic or event codes that activated during the initial start-up.

If the engine would not start before inspecting for debris and no debris was found in the HEUI pump, return to Step D in the diagnostic flow chart.If the engine would start before inspecting for debris and no debris was found in the HEUI pump, return to Step L in the diagnostic flow chart.If the pump is to be replaced, complete the checklist form in Special Instruction, REHS5031 that is provided with the service replacement part and insert the completed form back into the box containing the part that is being returned. Proceed to the section of this instruction titled "Oil Rail Cleaning Procedure" for the correct engine size that is being serviced.Oil Rail Cleaning Procedure For the C7 Engine

Illustration 12 g02702636

C7 Cylinder Head

Illustration 13 g02708256

The oil and fuel passages are the same for both the C7 and C9.

(6) Oil Rail for a HEUI fuel system

(7) Oil passage to injector bore

(8) Fuel passage

(9) Injector bore Note: Contain any oil and cleaner that will flow from the cylinder and the lines during the following process. Properly dispose of the oil and contaminated cleaner when work is complete.

Remove fuel injectors. Refer to Disassembly and Assembly for specific machine.

Install six plugs 9U-7080 Tapered Cap/Plug into the lower injector bores. The plugs will prevent oil, cleaners, and debris from entering the cylinders.

Remove the plugs from the front and rear of the cylinder head main oil gallery

Remove the pressure sensor from the cylinder head. Protect the sensor.

Clean out the two rail drain holes by removing their plugs and using the brake cleaner and long squirting straw to flush these passages to the oil rail.

Using the solvent gun with and without the