Information injection-pump assembly

ZEXEL

104741-1410

1047411410

ISUZU

8944528310

8944528310

Rating:

Cross reference number

ZEXEL

104741-1410

1047411410

ISUZU

8944528310

8944528310

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

(Solenoid timer adjustment condition)

OFF OFF

OFF OFF

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

45.3

44

46.6

Boost pressure

mmHg

340

330

350

Average injection quantity

mm3/st.

49.5

49

50

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

62.2

61.7

62.7

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

42.9

39.4

46.4

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

27.3

26

28.6

Boost pressure

mmHg

205

195

215

Average injection quantity

mm3/st.

42.3

42.3

42.3

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

45.3

44

46.6

Boost pressure

mmHg

340

330

350

Average injection quantity

mm3/st.

49.5

48.5

50.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

62.2

61.2

63.2

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

53.2

49.2

57.2

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

27.5

24.5

30.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

13

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

27.5

24.5

30.5

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

9

7

11

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

9

7

11

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

95

75

115

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

75

115

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

490

470

510

Pressure with S/T OFF

kgf/cm2

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

608

579

637

Pressure with S/T OFF

kgf/cm2

6.2

5.9

6.5

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1020

1020

1020

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1600

1600

1600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

7.8

7.5

8.2

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

3.2

3

3.4

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

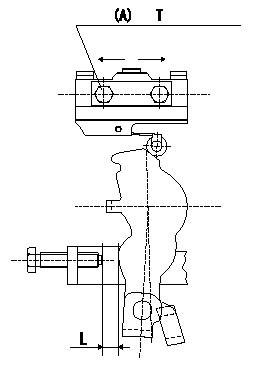

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1.Fix the control lever so that the distance between the control lever and the idling stopper bolt is L (control lever position: a).

2. In the above condition, adjust the installation position of the microswitch so that so that it turns OFF.

(A) = microswitch fixing bolt

----------

L=6.0+-0.2mm a=14deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0+-0.2mm

----------

L=6.0+-0.2mm a=14deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0+-0.2mm

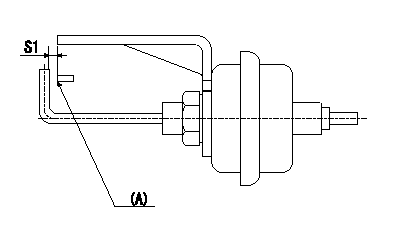

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

Information:

Events

The events are used in order to record a problem that is detected by the control system. Events are also used to document adverse engine operation. Events will be communicated to the service tool via the CDL. An event indicates that the control system has detected an engine problem. An event does not indicate an electronic problem. For example, the high exhaust temperature event is disabled if a problem with the temperature sensor is detected. (Events can be configured to be triggered on a diagnostic.)An event is identified by a numerical code. The EID (Event Identifier) identifies an engine problem or a problem with the machine. The service tool is used to display the EID. The service tool adds descriptive text for each EID in order to avoid mistakes in interpreting the codes.Logged Events

When an event is activated, information about the event is logged into permanent memory for the Electronic Control Module. The CDL can then request this information from the ECM. The CDL will display the following information for each logged event. Up to twenty five different events can be logged. Events are not automatically erased.

EID

FMI

Description of the event

Number of occurrences

The first time of occurrence

The last time of occurrenceEvents may be cleared from the memory of the ECM in order to use the CDL. Logged events can be configured so that a factory password is required to clear the event. Table 1 references the Event Codes that can be seen in order to use the Diesel Particulate Filter Monitor System.

Table 1

EID Description Security Level

194 Warning for the High Exhaust Temperature 1

194 Critical Warning for the High Exhaust Temperature 2

1049 Warning for the Pressure Inlet for the High Particulate Trap 1

1049 Critical Warning for the Pressure Inlet for the High Particulate Trap 2

The events are used in order to record a problem that is detected by the control system. Events are also used to document adverse engine operation. Events will be communicated to the service tool via the CDL. An event indicates that the control system has detected an engine problem. An event does not indicate an electronic problem. For example, the high exhaust temperature event is disabled if a problem with the temperature sensor is detected. (Events can be configured to be triggered on a diagnostic.)An event is identified by a numerical code. The EID (Event Identifier) identifies an engine problem or a problem with the machine. The service tool is used to display the EID. The service tool adds descriptive text for each EID in order to avoid mistakes in interpreting the codes.Logged Events

When an event is activated, information about the event is logged into permanent memory for the Electronic Control Module. The CDL can then request this information from the ECM. The CDL will display the following information for each logged event. Up to twenty five different events can be logged. Events are not automatically erased.

EID

FMI

Description of the event

Number of occurrences

The first time of occurrence

The last time of occurrenceEvents may be cleared from the memory of the ECM in order to use the CDL. Logged events can be configured so that a factory password is required to clear the event. Table 1 references the Event Codes that can be seen in order to use the Diesel Particulate Filter Monitor System.

Table 1

EID Description Security Level

194 Warning for the High Exhaust Temperature 1

194 Critical Warning for the High Exhaust Temperature 2

1049 Warning for the Pressure Inlet for the High Particulate Trap 1

1049 Critical Warning for the Pressure Inlet for the High Particulate Trap 2