Information injection-pump assembly

ZEXEL

104741-1393

1047411393

ISUZU

8944751621

8944751621

Rating:

Cross reference number

ZEXEL

104741-1393

1047411393

ISUZU

8944751621

8944751621

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

54.3

53.8

54.8

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

62.4

61.9

62.9

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

37.5

34

41

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

Average injection quantity

mm3/st.

45.7

45.7

45.7

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

54.3

53.3

55.3

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

62.4

61.4

63.4

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

57.8

52.3

63.3

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

19.7

16.7

22.7

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

11

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

19.7

16.7

22.7

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

80

60

100

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

80

60

100

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

530

510

550

Pressure with S/T OFF

kgf/cm2

5.4

5.2

5.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

441

412

470

Pressure with S/T OFF

kgf/cm2

4.5

4.2

4.8

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

530

510

550

Pressure with S/T OFF

kgf/cm2

5.4

5.2

5.6

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Pressure with S/T OFF

kPa

628

599

657

Pressure with S/T OFF

kgf/cm2

6.4

6.1

6.7

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

550

550

550

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T ON

mm

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

1.2

0.8

1.6

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

5

4.8

5.2

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Timer stroke with S/T OFF

mm

8.6

8.3

9

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

0.9

0.8

1

BCS stroke

mm

4.5

4.3

4.7

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

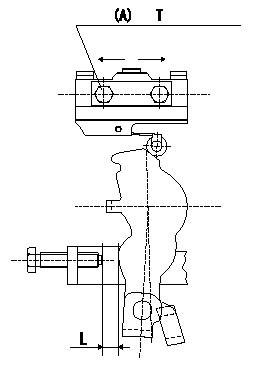

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1. Insert a shim L mm (control lever position: a) between the control lever and the idling stopper bolt.

2. Move the microswitch in the direction of the arrow so that it turns ON.

3. Move the microswitch again in the direction of the arrow and tighten the microswitch fixing bolt where it turns OFF.

Must change from ON to OFF at L1. [Lever angle b (from idle).]

(A): microswitch fixing bolt

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

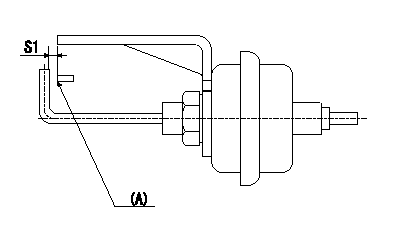

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 to the actuator and confirm the full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa(-400mmHg)

----------

S1=1+1mm

Information:

The Caterpillar Electronic Technician (ET)

Illustration 1 g00777826

The Caterpillar Electronic Technician (ET) is a software program that is used to access data. The service technician can use the Caterpillar Electronic Technician in order to perform maintenance work on the machine. Some of the options that are available with the Caterpillar Electronic Technician are listed below:

View Diagnostic codes. See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes".

View the status of parameters.

Clear active diagnostic codes and clear logged diagnostic codes

Perform calibration of machine systems.

Program the ECM (Flash). This is done with the "WINflash" program. See Testing and Adjusting, "Electronic Control Module (ECM) - Flash Program".

Print reports.The following list contains some of the diagnostic functions and programming functions that are performed by the service tools.

The failures of the ECM system are displayed.

The status of most of the inputs and the outputs are displayed.

The settings for the ECM are displayed.

Display the status of the input and output parameters in real time.

Display the clock hour of the internal diagnostic clock.

The number of occurrences and the clock hour of the first occurrence and the last occurrence is displayed for each logged diagnostic code.

The definition for each logged diagnostic code and each event is displayed.

Load new FLASH software.See Troubleshooting, "Diagnostic Code List" for the list of diagnostic codes for the ECM.See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes". Diagnostic information is accessed with the following drop down menus:

Active diagnostic codes

Logged diagnostic codesSensor Diagnostics

The following tables show the conditions that the diagnostic codes are set for each sensor. If any of the diagnostic codes are active, the System Problem for the LED will be turned on. During the Debounce time, the affected parameter will remain at the last good value. After the Debounce time, the affected parameter will be set to the default value. Refer to Table 1.

Table 1

Sensor Sample Period (mS) Too Low Too High Defaults

Inlet Pressure (gauge) Code Condition Debounce Code Condition Debounce NA

1 81-4 Input < 0.5 VDC 5 sec on

5 sec off 81-3 Input greater than 4.5 VDC 5 sec on

5 sec off NA

Exhaust Temperature 1 535-4 Input < 1.5 VDC 5 sec on

5 sec off 535-3 Input greater than 4.0 VDC 5 sec on

5 sec off NA Temperature Sensor

Table 2 refers to the properties of the temperature sensor.

Table 2

Function Part Number Measure Range Output Accuracy Power Supply Sensor Mounting Mating

Exhaust Temperature 280-3921

50 °C (122 °F)to

850 °C (1562 °F) N/A

500° 5°C (932° 9°F) to

850° 5°C (1562° 9°F) 5V (+/- 0.5) Thread Size: M14 X 1.5

Probe Length:

70 mm (2.7559 inch) from flange to tip 230-5008 Connector Plug As Pressure Sensor

Table 3

Function PN Max Pressure Measure Burst Pressure Power

Illustration 1 g00777826

The Caterpillar Electronic Technician (ET) is a software program that is used to access data. The service technician can use the Caterpillar Electronic Technician in order to perform maintenance work on the machine. Some of the options that are available with the Caterpillar Electronic Technician are listed below:

View Diagnostic codes. See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes".

View the status of parameters.

Clear active diagnostic codes and clear logged diagnostic codes

Perform calibration of machine systems.

Program the ECM (Flash). This is done with the "WINflash" program. See Testing and Adjusting, "Electronic Control Module (ECM) - Flash Program".

Print reports.The following list contains some of the diagnostic functions and programming functions that are performed by the service tools.

The failures of the ECM system are displayed.

The status of most of the inputs and the outputs are displayed.

The settings for the ECM are displayed.

Display the status of the input and output parameters in real time.

Display the clock hour of the internal diagnostic clock.

The number of occurrences and the clock hour of the first occurrence and the last occurrence is displayed for each logged diagnostic code.

The definition for each logged diagnostic code and each event is displayed.

Load new FLASH software.See Troubleshooting, "Diagnostic Code List" for the list of diagnostic codes for the ECM.See Troubleshooting, "Using the Caterpillar Electronic Technician to Determine Diagnostic Codes". Diagnostic information is accessed with the following drop down menus:

Active diagnostic codes

Logged diagnostic codesSensor Diagnostics

The following tables show the conditions that the diagnostic codes are set for each sensor. If any of the diagnostic codes are active, the System Problem for the LED will be turned on. During the Debounce time, the affected parameter will remain at the last good value. After the Debounce time, the affected parameter will be set to the default value. Refer to Table 1.

Table 1

Sensor Sample Period (mS) Too Low Too High Defaults

Inlet Pressure (gauge) Code Condition Debounce Code Condition Debounce NA

1 81-4 Input < 0.5 VDC 5 sec on

5 sec off 81-3 Input greater than 4.5 VDC 5 sec on

5 sec off NA

Exhaust Temperature 1 535-4 Input < 1.5 VDC 5 sec on

5 sec off 535-3 Input greater than 4.0 VDC 5 sec on

5 sec off NA Temperature Sensor

Table 2 refers to the properties of the temperature sensor.

Table 2

Function Part Number Measure Range Output Accuracy Power Supply Sensor Mounting Mating

Exhaust Temperature 280-3921

50 °C (122 °F)to

850 °C (1562 °F) N/A

500° 5°C (932° 9°F) to

850° 5°C (1562° 9°F) 5V (+/- 0.5) Thread Size: M14 X 1.5

Probe Length:

70 mm (2.7559 inch) from flange to tip 230-5008 Connector Plug As Pressure Sensor

Table 3

Function PN Max Pressure Measure Burst Pressure Power