Information injection-pump assembly

ZEXEL

104741-1382

1047411382

ISUZU

8944751610

8944751610

Rating:

Cross reference number

ZEXEL

104741-1382

1047411382

ISUZU

8944751610

8944751610

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

59.7

59.2

60.2

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

75.3

74

76.6

Boost pressure

mmHg

565

555

575

Average injection quantity

mm3/st.

68.3

67.8

68.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

37

33.5

40.5

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

26.7

25.4

28

Boost pressure

mmHg

200

190

210

Average injection quantity

mm3/st.

49.6

49.6

49.6

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

59.7

58.7

60.7

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

75.3

74

76.6

Boost pressure

mmHg

565

555

575

Average injection quantity

mm3/st.

68.3

67.3

69.3

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

60.9

55.4

66.4

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.9

19.9

25.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

8

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

22.9

19.9

25.9

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

75

115

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

92.5

70

115

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

471

451

491

Pressure with S/T OFF

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

471

451

491

Pressure with S/T OFF

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

647

608

686

Pressure with S/T OFF

kgf/cm2

6.6

6.2

7

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T ON

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1300

1300

1300

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1450

1450

1450

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

3

2.8

3.2

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

8.6

8.3

9

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

4.3

4.1

4.5

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

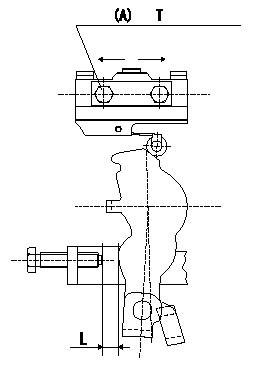

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1.Fix the control lever so that the distance between the control lever and the idling stopper bolt is L (control lever position: a).

2. In the above condition, adjust the installation position of the microswitch so that so that it turns OFF.

Must change from ON to OFF at L1. [Lever angle b (from idle).]

(A): microswitch fixing bolt

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

----------

L=6.0mm L1=5.6~6.4mm a=14deg b=13~15deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

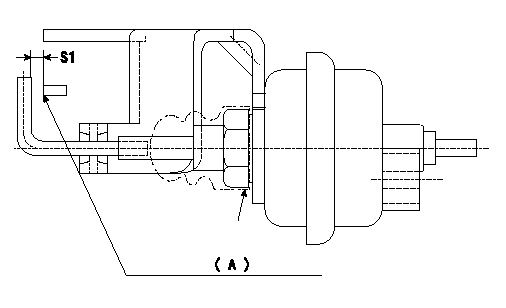

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 kPa {P2 mmHg} to the actuator and confirm that it moves through its full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

Information:

Connector Contact Description for the Exhaust Particulate Filter

Table 1 describes the necessary electronic connections to the ECM.

Table 1

Pin Number Description Pin Number Description

J1-1 No Connection J1-36 Exhaust Pressure Active Analog Input 1

J1-2 No Connection J1-37 Exhaust Temperature Active Analog Input 2

J1-3 No Connection J1-38 Alarm Data Link

J1-4 RS-485 TX + J1-39 No Connection

J1-5 RS-485 TX - J1-40 No Connection

J1-6 RS-485 Shield J1-41 CAN Port 2 Low

J1-7 PWM/Freq/STG 9 J1-42 CAN Port 1 Shield

J1-8 CDL/ATA + J1-43 RS-232 Port 2 GND

J1-9 CDL/ATA - J1-44 PWM/Freq/STG 13

J1-10 PWM/Freq/STG 10 J1-45 STG 1

J1-11 No Connection J1-46 STG 2

J-12 No Connection J1-47 STG 3

J-13 RS-232 Port 1 TX J1-48 CAN Port 2 Shield

J-14 No Connection J1-49 PWM/Freq/STG 7

J-15 No Connection J1-50 CAN Port 1 High

J-16 No Connection J1-51 PWM/Freq/STG 8

J-17 RS-485 RX + J-52 + Battery

J-18 RS-485 RX - J-53 + Battery

J1-19 UPS Backup Battery (12V) J1-54 R-Terminal

J1-20 PWM/Freq/STG 11 J1-55 STG 4

J1-21 No Connection J1-56 PWM/STG 5

J1-22 RS-232 Port 1 RX J1-57 PWM/STG 6

J1-23 RS-232 Port 1 DTR J1=58 System Status LED (300mA Sinking Driver)

J1-24 No Connection J1-59 System Problem LED (300mA Sinking Driver 2)

J1-25 No Connection J1-60 Over Press LED (300mA Sinking Driver 3)

J1-26 PWM/Freq/STG 14 J1-61 Over Temp LED (300mA Sinking Driver 4)

J1-27 RS-232 Port 2 TX J1-62 RS-232 Port 3 TX

J1-28 PWM/Freq/STG 12 J1-63 RS-232 Port 3 RX

J1-29 No Connection J1-64 RS-232 Port 3 GND

J1-30 RS-232 Port 1 DCD J1-65 - Battery

J1-31 RS-232 Port 1 GND J1-66 STB 1

J1-32 No Connection J1-67 - Battery

J1-33 CAN Port 2 High J1-68 Aux +5V Supply

J1-34 CAN Port 1 Low J1-69 Aux Supply Return

J1-35 RS-232 Port RX J1-70 Keyswitch

Table 1 describes the necessary electronic connections to the ECM.

Table 1

Pin Number Description Pin Number Description

J1-1 No Connection J1-36 Exhaust Pressure Active Analog Input 1

J1-2 No Connection J1-37 Exhaust Temperature Active Analog Input 2

J1-3 No Connection J1-38 Alarm Data Link

J1-4 RS-485 TX + J1-39 No Connection

J1-5 RS-485 TX - J1-40 No Connection

J1-6 RS-485 Shield J1-41 CAN Port 2 Low

J1-7 PWM/Freq/STG 9 J1-42 CAN Port 1 Shield

J1-8 CDL/ATA + J1-43 RS-232 Port 2 GND

J1-9 CDL/ATA - J1-44 PWM/Freq/STG 13

J1-10 PWM/Freq/STG 10 J1-45 STG 1

J1-11 No Connection J1-46 STG 2

J-12 No Connection J1-47 STG 3

J-13 RS-232 Port 1 TX J1-48 CAN Port 2 Shield

J-14 No Connection J1-49 PWM/Freq/STG 7

J-15 No Connection J1-50 CAN Port 1 High

J-16 No Connection J1-51 PWM/Freq/STG 8

J-17 RS-485 RX + J-52 + Battery

J-18 RS-485 RX - J-53 + Battery

J1-19 UPS Backup Battery (12V) J1-54 R-Terminal

J1-20 PWM/Freq/STG 11 J1-55 STG 4

J1-21 No Connection J1-56 PWM/STG 5

J1-22 RS-232 Port 1 RX J1-57 PWM/STG 6

J1-23 RS-232 Port 1 DTR J1=58 System Status LED (300mA Sinking Driver)

J1-24 No Connection J1-59 System Problem LED (300mA Sinking Driver 2)

J1-25 No Connection J1-60 Over Press LED (300mA Sinking Driver 3)

J1-26 PWM/Freq/STG 14 J1-61 Over Temp LED (300mA Sinking Driver 4)

J1-27 RS-232 Port 2 TX J1-62 RS-232 Port 3 TX

J1-28 PWM/Freq/STG 12 J1-63 RS-232 Port 3 RX

J1-29 No Connection J1-64 RS-232 Port 3 GND

J1-30 RS-232 Port 1 DCD J1-65 - Battery

J1-31 RS-232 Port 1 GND J1-66 STB 1

J1-32 No Connection J1-67 - Battery

J1-33 CAN Port 2 High J1-68 Aux +5V Supply

J1-34 CAN Port 1 Low J1-69 Aux Supply Return

J1-35 RS-232 Port RX J1-70 Keyswitch