Information injection-pump assembly

ZEXEL

104741-1380

1047411380

ISUZU

8944528170

8944528170

Rating:

Cross reference number

ZEXEL

104741-1380

1047411380

ISUZU

8944528170

8944528170

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

900

900

900

Boost pressure

kPa

45.3

44

46.6

Boost pressure

mmHg

340

330

350

Average injection quantity

mm3/st.

55

54.5

55.5

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

66.1

65.6

66.6

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

500

500

500

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

39.9

36.4

43.4

Oil temperature

degC

48

46

50

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

27.3

26

28.6

Boost pressure

mmHg

205

195

215

Average injection quantity

mm3/st.

46.4

46.4

46.4

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

900

900

900

Boost pressure

kPa

45.3

44

46.6

Boost pressure

mmHg

340

330

350

Average injection quantity

mm3/st.

55

54

56

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1150

1150

1150

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

66.1

65.1

67.1

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

1900

1900

1900

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

64.2

60.2

68.2

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

17.9

14.9

20.9

Difference in delivery

mm3/st.

4.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2400

2400

2400

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

8

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2300

2300

2300

Boost pressure

kPa

80

78.7

81.3

Boost pressure

mmHg

600

590

610

Average injection quantity

mm3/st.

17.9

14.9

20.9

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

6

4

8

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

75

115

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

92.5

70

115

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

385

385

385

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Oil temperature

degC

50

48

52

Remarks

MEASURE

MEASURE

Stop lever angle

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

441

421

461

Pressure with S/T OFF

kgf/cm2

4.5

4.3

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

441

421

461

Pressure with S/T OFF

kgf/cm2

4.5

4.3

4.7

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Pressure with S/T OFF

kPa

569

530

608

Pressure with S/T OFF

kgf/cm2

5.8

5.4

6.2

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

4.3

4.1

4.5

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

820

820

820

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T ON

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1470

1470

1470

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1700

1700

1700

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

4.3

4.1

4.5

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Timer stroke with S/T OFF

mm

9.4

9.1

9.8

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5.5

5.4

5.6

MS dimension

mm

1

0.9

1.1

BCS stroke

mm

4.2

4

4.4

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

37

32

42

Test data Ex:

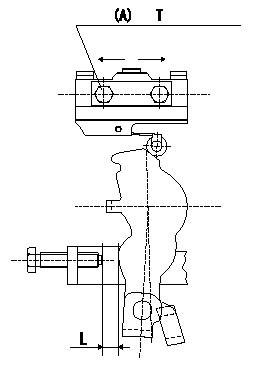

0000001801 MICROSWITCH ADJUSTMENT

Microswitch adjustment

1.Fix the control lever so that the distance between the control lever and the idling stopper bolt is L (control lever position: a).

2. In the above condition, adjust the installation position of the microswitch so that so that it turns OFF.

(A) = microswitch fixing bolt

----------

L=6.0mm a=14deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

----------

L=6.0mm a=14deg

----------

T=2~3N-m(0.2~0.3kgf-m) L=6.0mm

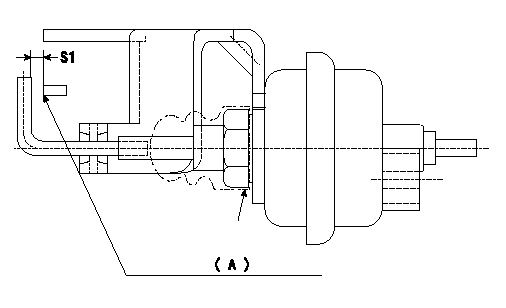

0000001901 V-FICD ADJUSTMENT

Adjustment of the V-FICD

1. Adjust the actuator rod to obtain S1.

2. Apply negative pressure P1 kPa {P2 mmHg} to the actuator and confirm that it moves through its full stroke.

(A) Control lever (Idling position)

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

----------

S1=1+1mm P1=-53.3kPa P2=-400mmHg

----------

S1=1+1mm

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Some of the 3408E engines and 3412E engines in the above listed machines may experience hard starting or low power due to oil that is leaking past the poppet valve in the injector. The oil leakage is caused by the operating conditions at either low idle or high idle. Excessive oil leakage can reduce actuation pressure to the fuel injector. This may prevent fuel injection.Solution

Electrical shock hazard. The electronic unit injector system uses 90-120 volts.

Follow the proper troubleshooting procedure for the correct engine. If the problem is not located and the symptoms that are listed above continue, remove the engine valve covers. Electrically disable the injectors. Crank the engine. Watch the spill ports of the injector for oil leakage. A small amount of oil leakage is acceptable. A continuous stream of oil may mean leakage from the poppet valve. Excessive leakage from the poppet valve may prevent fuel injection.Note: Normal oil pressure during cranking should be 5 MPa (725 psi). Oil pressure below 5 MPa (725 psi) may indicate excessive oil leakage in injectors. Do not replace the oil pump. Service personnel should replace the injectors that have a continuous flow of oil from the oil ports. Injectors that have a continuous flow of oil and injectors that are within the guidelines of warranty can be returned. Injectors that do not have a continuous flow of oil should not be replaced. Injectors that do not have a continuous flow of oil should not be returned.Note: For additional information on the operation of Hydraulic Electronic Unit Injectors HEUI, refer to CD, RENR1390.

Illustration 1 g01308874

(1) Oil drain portThe oil drain ports are located underneath the solenoid. This will direct the oil flow downward. Some oil may also leak from the rectangular slots at the side of the solenoid. Excess oil leakage will still be visible on the cylinder head.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Some of the 3408E engines and 3412E engines in the above listed machines may experience hard starting or low power due to oil that is leaking past the poppet valve in the injector. The oil leakage is caused by the operating conditions at either low idle or high idle. Excessive oil leakage can reduce actuation pressure to the fuel injector. This may prevent fuel injection.Solution

Electrical shock hazard. The electronic unit injector system uses 90-120 volts.

Follow the proper troubleshooting procedure for the correct engine. If the problem is not located and the symptoms that are listed above continue, remove the engine valve covers. Electrically disable the injectors. Crank the engine. Watch the spill ports of the injector for oil leakage. A small amount of oil leakage is acceptable. A continuous stream of oil may mean leakage from the poppet valve. Excessive leakage from the poppet valve may prevent fuel injection.Note: Normal oil pressure during cranking should be 5 MPa (725 psi). Oil pressure below 5 MPa (725 psi) may indicate excessive oil leakage in injectors. Do not replace the oil pump. Service personnel should replace the injectors that have a continuous flow of oil from the oil ports. Injectors that have a continuous flow of oil and injectors that are within the guidelines of warranty can be returned. Injectors that do not have a continuous flow of oil should not be replaced. Injectors that do not have a continuous flow of oil should not be returned.Note: For additional information on the operation of Hydraulic Electronic Unit Injectors HEUI, refer to CD, RENR1390.

Illustration 1 g01308874

(1) Oil drain portThe oil drain ports are located underneath the solenoid. This will direct the oil flow downward. Some oil may also leak from the rectangular slots at the side of the solenoid. Excess oil leakage will still be visible on the cylinder head.