Information injection-pump assembly

ZEXEL

104741-1101

1047411101

ISUZU

8941403872

8941403872

Rating:

Cross reference number

ZEXEL

104741-1101

1047411101

ISUZU

8941403872

8941403872

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

44.3

43.8

44.8

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

44.9

41.4

48.4

Difference in delivery

mm3/st.

5

Oil temperature

degC

48

46

50

Injection timing adjustment_03

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

40.4

38.4

42.4

Difference in delivery

mm3/st.

4.5

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

44.3

43.3

45.3

Difference in delivery

mm3/st.

3.5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

46.9

44.9

48.9

Difference in delivery

mm3/st.

5.5

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1800

1800

1800

Average injection quantity

mm3/st.

45

42.5

47.5

Difference in delivery

mm3/st.

5

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

20.1

17.1

23.1

Difference in delivery

mm3/st.

6

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

5

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

20.1

17.1

23.1

Difference in delivery

mm3/st.

6

Oil temperature

degC

52

50

54

Governor adjustment

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

8

6

10

Difference in delivery

mm3/st.

2

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

75

115

Basic

*

Oil temperature

degC

48

46

50

Remarks

Full

Full

Timer adjustment_02

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

95

75

115

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1450

1450

1450

Overflow quantity

cm3/min

510

380

640

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle

Pump speed

r/min

1450

1450

1450

Pressure with S/T OFF

kPa

510

490

530

Pressure with S/T OFF

kgf/cm2

5.2

5

5.4

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

Stop lever angle_02

Pump speed

r/min

1450

1450

1450

Pressure with S/T OFF

kPa

510

490

530

Pressure with S/T OFF

kgf/cm2

5.2

5

5.4

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1950

1950

1950

Pressure with S/T OFF

kPa

657

628

686

Pressure with S/T OFF

kgf/cm2

6.7

6.4

7

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1450

1450

1450

Timer stroke with S/T OFF

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

Remarks

OFF

OFF

_02

Pump speed

r/min

560

560

560

Timer stroke with S/T ON

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1270

1270

1270

Timer stroke with S/T OFF

mm

0.5

0.5

0.5

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1450

1450

1450

Timer stroke with S/T OFF

mm

1.9

1.7

2.1

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1950

1950

1950

Timer stroke with S/T OFF

mm

5.7

5.4

6.1

Oil temperature

degC

50

48

52

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001501

Pump speed

r/min

1000

1000

1000

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Average injection quantity

mm3/st.

39.5

39.5

39.5

Decrease qty

mm3/st.

4.7

3.7

5.7

Decrease rate

%

11

8

14

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1000

1000

1000

Height

m

0

0

0

Atmospheric pressure difference

kPa

0

0

0

Atmospheric pressure difference

mmHg

0

0

0

Decrease qty

mm3/st.

0

0

0

Decrease rate

%

0

0

0

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1000

1000

1000

Height

m

500

500

500

Atmospheric pressure difference

kPa

-5.9

-9.2

-2.6

Atmospheric pressure difference

mmHg

-44

-46.5

-41.5

Oil temperature

degC

50

48

52

Remarks

Point of inflection

Point of inflection

_04

Pump speed

r/min

1000

1000

1000

Height

m

2000

2000

2000

Atmospheric pressure difference

kPa

-21.9

-21.9

-21.9

Atmospheric pressure difference

mmHg

-164

-164

-164

Decrease qty

mm3/st.

-4.7

-5.7

-3.7

Decrease rate

%

-11

-14

-8

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

2.8

2.7

2.9

KF dimension

mm

5

4.9

5.1

MS dimension

mm

1

0.9

1.1

Pre-stroke

mm

0.45

0.43

0.47

Control lever angle alpha

deg.

18

14

22

Control lever angle beta

deg.

35

30

40

Test data Ex:

0000001501 ANEROID COMPENSATOR

ACS adjustment

Full load injection quantity at high altitudes and ACS adjusting method

1. Full load injection quantity adjustment

(1)Remove the ACS cover and remove the bellows and adjusting shim.

(2)Perform all adjustments as per the adjustment standard except for ACS adjustment.

2. ACS adjustment

(1)Assemble the ACS cover, bellows and adjusting shim.

(2)At pump speed N1, adjust using a shim to obtain the decrease for the altitude shown in the table.

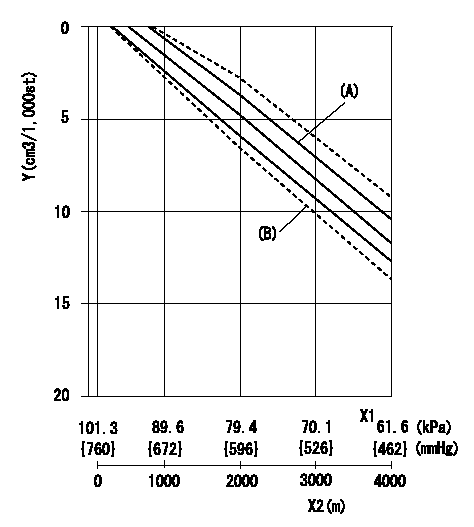

X1 = atmospheric pressure

X2 = altitude

Y = decrease quantity

(A) = adjustment value

(B) = test value

----------

N1=1000r/min

----------

----------

N1=1000r/min

----------

Information:

Table 1

Sales Model Adaptable to Machines Effective in Production with Machines

D3K 2 S/N:JPJ1-199 S/N:JPJ200-UP

S/N:KL21-208 S/N:KL2209-UP

S/N:LT31-113 S/N:LT3114-UP

S/N:FT31-102 S/N:FT3103-UP

S/N:KF21-174 S/N:KF2175-UP

D4K 2 S/N:KR21-203 S/N:KR2204-UP

S/N:RT31-130 S/N:RT3131-UP

S/N:KM21-196 S/N:KM2197-UP

S/N:MT31-119 S/N:MT3120-UP

D5K 2 S/N:KY21-357 S/N:KY2358-UP

S/N:RRE1-232 S/N:RRE233-UP

S/N:YT31-153 S/N:YT3154-UP

S/N:KW21-308 S/N:KW2309-UP

S/N:WT31-145 S/N:WT3146-UP In the event, the original bolt should come loose or is lost, use one of the following procedures and parts list for reworking the latch assembly.Rework Procedure

Table 2

New Parts List

Item Quantity Part Number Description

1 1 275-0571 Latch Cam

2 1 7X-2619 Bolt

3 1 9X-8256 Washer

4 1 275-0572 Latch As

Illustration 1 g06026857Procedure if the original cam latch retaining bolt is loose

Illustration 2 g06025999

Remove bolt (2), keeping cam latch (1) in position.

Apply Loctite 243 to the threads of bolt (2). Torque the bolt to 6 1 N m (53 9 lb in) using a torque wrench.Procedure if only the original cam latch bolt and cam latch are missing

Illustration 3 g06026021

Install new cam latch (1) to the latch body.

Replace missing retaining bolt with a 7X-2619 Bolt (2) and 9X-8256 Washer (3). This washer is required as the new bolt is too long and will bottom out in the latch body before tightening. Install using Loctite 243. Torque the bolt to 6 1 N m (53 9 lb in) using a torque wrench.Procedure if the original cam latch retaining bolt, cam latch and latch assembly are missing

Illustration 4 g06026825

Illustration 5 g06026826

Illustration 6 g06026831

(E) Side 1 of Retaining Nut

(F) Side 2 of Retaining Nut

Install new latch housing (A), with non-metallic washer (on outside of door) and Latch body/ handle (4) in door.Note: Orient two surfaces (C)and handle as shown in Illustration 5. Lock indicator on outside of handle is at the top.

Secure housing with retaining nut (B) and torque to 15 3 N m (11 2 lb ft), using a torque wrench.Note: During assembly, use four nubs (D) on Side (E) of nut against door.

Remove original bolt (C).

Install latch cam (1).

Apply Loctite 243 to the threads on the original bolt (C). Torque the bolt to 6 1 N m (53 9 lb in).Note: Use torque wrench for tightening.