Information injection-pump assembly

ZEXEL

104740-9970

1047409970

NISSAN-DIESEL

1670030N01

1670030n01

Rating:

Cross reference number

ZEXEL

104740-9970

1047409970

NISSAN-DIESEL

1670030N01

1670030n01

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

44.1

45.1

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

8.9

5.4

12.4

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

27.8

32.8

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

38

35.9

40.1

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

43.6

45.6

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

43.5

41.5

45.5

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

28.3

32.3

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Governor adjustment_03

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

258

522

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

489

360

618

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

598.5

569

628

Pressure with S/T OFF

kgf/cm2

6.1

5.8

6.4

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.2

3.8

4.6

Timer stroke with S/T OFF

mm

2.5

2.3

2.7

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.2

3.7

4.7

Timer stroke with S/T OFF

mm

2.5

2.2

2.8

_03

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T OFF

mm

4.6

4

5.2

_04

Pump speed

r/min

2550

2550

2550

Timer stroke with S/T OFF

mm

7

6.6

7.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

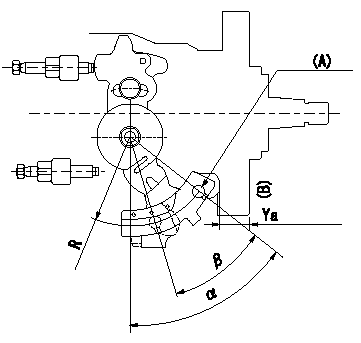

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle measuring position

(B) = flange face

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

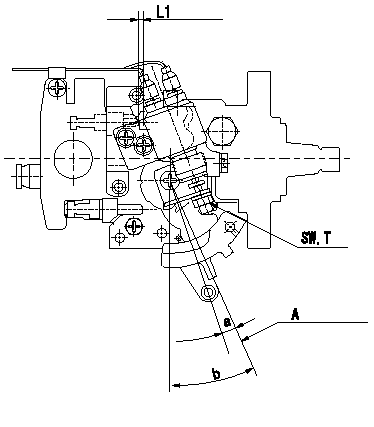

0000001901 ACCELERATOR SWITCH ADJ

Adjustment of the accelerator switch

ON - OFF changeover point: from idle to c (shim thickness L1 mm)

Idle-d: ON

e-full: OFF

A = idle lever position

----------

c=5+-2deg d=5deg e=5deg L1=3.3+-0.13mm

----------

SW=SW10 T=6~9N-m(0.6~0.9Kgf-m) a=5+-2deg b=25+-2deg L1=3.3mm

----------

c=5+-2deg d=5deg e=5deg L1=3.3+-0.13mm

----------

SW=SW10 T=6~9N-m(0.6~0.9Kgf-m) a=5+-2deg b=25+-2deg L1=3.3mm

Information:

Batteries

Install batteries that will provide adequate cold cranking amps (CCA) in order to start the engine and operate the engine at the coldest expected temperatures. Maintain proper battery electrolyte level. Keep all batteries fully charged to a corrected specific gravity of 1.250 or above and keep the batteries warm. Heating of the battery compartment or storage in a warm location will maximize the cranking power of the battery. The temperature of the batteries has a considerable effect on the available power. The batteries will not have enough power for cranking the engine and starting the engine if the batteries are too cold, even with a warm engine. Batteries typically have only fifty percent of the capability at −10 °C (14 °F) versus 27 °C (81 °F). Only ten percent of the original power is available at a temperature of −35 °C (−31 °F). Check the condition of the batteries and the electrolyte level in each battery cell except for maintenance free batteries. Remove the battery filler caps. Maintain the electrolyte level to the bottom of the openings for the battery filler caps with distilled water. If distilled water is not available, use clean water, that is low in minerals. Do not use artificially softened water or drinking water. The salt in artificially softened water will damage the efficiency of your batteries. At the proper charging rate in a moderate climate, a battery should not require more than 30 cc (1 oz) of water per cell per week. Check the cells weekly in arctic temperatures. The cell water usage could be higher.Block Heaters

A cylinder block coolant heater can improve the startability and a cylinder block coolant heater can reduce the warm-up time by heating the coolant that surrounds the combustion chambers. A cylinder block coolant heater that is powered by electricity can be activated immediately after the engine is stopped. A cylinder block coolant heater will reduce the temperature that will require ether for starting the engine. An effective block heater is a 1250 watt to 1500 watt unit. Contact your truck dealer for more information.Air Inlet Heaters and Ether Starting Systems

If equipped with an air inlet heater (AIH) for cold weather starting, do not use types of starting aids such as ether. Such use could result in an explosion and injury.

When starting the engine with ether, follow these starting procedure instructions carefully. Use ether sparingly and spray it ONLY WHILE CRANKING THE ENGINE. Excessive ether use can cause piston and ring damage. Ether should be used only for cold weather starting.

As temperatures drop below 0 °C (32 °F), starting a cold engine may require assistance in the form of ether starting aids or air inlet heaters. An automatic metered ether injection system is preferred over a manual system. An automatic system reduces the risk of engine damage by minimizing the operator's responsibility in order to correctly determine the quantity of ether that is required. Excessive ether will damage the engine and excessive ether will void the manufacturer's

Install batteries that will provide adequate cold cranking amps (CCA) in order to start the engine and operate the engine at the coldest expected temperatures. Maintain proper battery electrolyte level. Keep all batteries fully charged to a corrected specific gravity of 1.250 or above and keep the batteries warm. Heating of the battery compartment or storage in a warm location will maximize the cranking power of the battery. The temperature of the batteries has a considerable effect on the available power. The batteries will not have enough power for cranking the engine and starting the engine if the batteries are too cold, even with a warm engine. Batteries typically have only fifty percent of the capability at −10 °C (14 °F) versus 27 °C (81 °F). Only ten percent of the original power is available at a temperature of −35 °C (−31 °F). Check the condition of the batteries and the electrolyte level in each battery cell except for maintenance free batteries. Remove the battery filler caps. Maintain the electrolyte level to the bottom of the openings for the battery filler caps with distilled water. If distilled water is not available, use clean water, that is low in minerals. Do not use artificially softened water or drinking water. The salt in artificially softened water will damage the efficiency of your batteries. At the proper charging rate in a moderate climate, a battery should not require more than 30 cc (1 oz) of water per cell per week. Check the cells weekly in arctic temperatures. The cell water usage could be higher.Block Heaters

A cylinder block coolant heater can improve the startability and a cylinder block coolant heater can reduce the warm-up time by heating the coolant that surrounds the combustion chambers. A cylinder block coolant heater that is powered by electricity can be activated immediately after the engine is stopped. A cylinder block coolant heater will reduce the temperature that will require ether for starting the engine. An effective block heater is a 1250 watt to 1500 watt unit. Contact your truck dealer for more information.Air Inlet Heaters and Ether Starting Systems

If equipped with an air inlet heater (AIH) for cold weather starting, do not use types of starting aids such as ether. Such use could result in an explosion and injury.

When starting the engine with ether, follow these starting procedure instructions carefully. Use ether sparingly and spray it ONLY WHILE CRANKING THE ENGINE. Excessive ether use can cause piston and ring damage. Ether should be used only for cold weather starting.

As temperatures drop below 0 °C (32 °F), starting a cold engine may require assistance in the form of ether starting aids or air inlet heaters. An automatic metered ether injection system is preferred over a manual system. An automatic system reduces the risk of engine damage by minimizing the operator's responsibility in order to correctly determine the quantity of ether that is required. Excessive ether will damage the engine and excessive ether will void the manufacturer's