Information injection-pump assembly

ZEXEL

104740-9910

1047409910

NISSAN-DIESEL

1670022T03

1670022t03

Rating:

Cross reference number

ZEXEL

104740-9910

1047409910

NISSAN-DIESEL

1670022T03

1670022t03

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.3

51.8

52.8

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.1

5.6

14.6

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

34.2

31.7

36.7

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

42.9

40.8

45

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.3

51.3

53.3

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

52.8

50.8

54.8

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

34.2

32.2

36.2

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.3

5.3

9.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

3

Governor adjustment_03

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.3

5.3

9.3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

390

258

522

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

489

360

618

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T ON

kPa

618

579

657

Pressure with S/T ON

kgf/cm2

6.3

5.9

6.7

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

598.5

569

628

Pressure with S/T OFF

kgf/cm2

6.1

5.8

6.4

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.3

3.9

4.7

Timer stroke with S/T OFF

mm

2.6

2.4

2.8

Basic

*

_02

Pump speed

r/min

700

700

700

Timer stroke with S/T ON

mm

2.8

2

3.6

_03

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.3

3.8

4.8

Timer stroke with S/T OFF

mm

2.6

2.3

2.9

_04

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T ON

mm

6.5

5.7

7.3

Timer stroke with S/T OFF

mm

4.9

4.3

5.5

_05

Pump speed

r/min

2550

2550

2550

Timer stroke with S/T OFF

mm

7.3

6.8

7.8

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

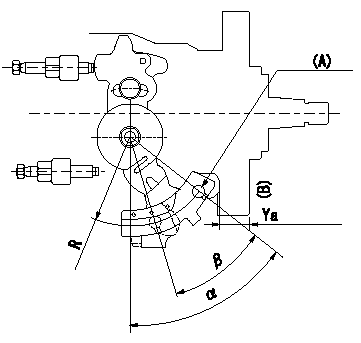

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle measuring position

(B) = flange face

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

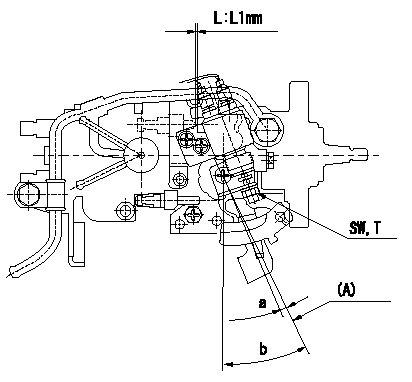

0000001901 ACCELERATOR SWITCH ADJ

Adjustment of the accelerator switch

ON - OFF changeover point: from idle to c (shim thickness L = L1)

Idle-d: ON

e-full: OFF

L:Thickness of the shim

(A): Position of the idle lever

----------

c=5+-2deg d=5deg e=5deg L1=3.3+-0.13mm

----------

SW=SW10 T=6~9N-m(0.6~0.9Kgf-m) a=5+-2deg b=(25+-2)deg L1=3.3mm

----------

c=5+-2deg d=5deg e=5deg L1=3.3+-0.13mm

----------

SW=SW10 T=6~9N-m(0.6~0.9Kgf-m) a=5+-2deg b=(25+-2)deg L1=3.3mm

Information:

Oils that have more than 1% total sulfated ash should not be used in aftertreatment device equipped engines.In order to achieve expected ash service intervals, performance, and life, aftertreatment device equipped diesel engines require the use of Cat DEO-ULS or oils meeting the Cat ECF-3 specification and the API CJ-4 oil category. Use of oils with more than 1% total sulfated ash in aftertreatment device equipped engines will cause the need for more frequent ash service intervals, and/or cause loss of performance. Refer to your engine specific Operation and Maintenance Manual, and refer to your aftertreatment device documentation for additional guidance.

API category oils that have not met the requirements of at least one Cat ECF specification may cause reduced engine life.

In selecting oil for any engine application, both the oil viscosity and oil performance category/specification as specified by the engine manufacturer must be defined and satisfied. Using only one of these parameters will not sufficiently define oil for an engine application.

In order to make the proper diesel engine oil viscosity grade choice, refer to the applicable “Lubricant Viscosities for Ambient Temperatures” table in this Special Publication.

Failure to follow these oil recommendations can cause shortened engine service life due to deposits and/or excessive wear.

Total Base Number (TBN) and Fuel Sulfur Levels for Direct Injection (DI) Diesel Engines

The minimum required Total Base Number (TBN) for oil depends on the fuel sulfur level. The TBN for new oil is typically determined by the "ASTM D2896" procedure. For direct injection engines that use distillate fuel, the following guidelines apply.

Table 3

TBN recommendations for applications in Cat engines

Fuel Sulfur Level percent (ppm) Cat Engine Oils TBN of Commercial Engine Oils

≤0.05 percent (≤500 ppm) Cat DEO-ULS, Cat DEO Min 7

0. 1 - 0.05 percent (1000-500 ppm) Cat DEO-ULS, Cat DEO Min 7

Above 0.1 percent (above 1000 ppm) Cat DEO Min 10 Reaching one half of new oil TBN is one of the condemning factors for diesel engine oil. In order to help provide the best protection for your engine, Cat S O S Services oil analysis is the preferred method for determining oil life. TBN of the oil is typically measured using "ASTM D2896" and/or the "ASTM D4739" test methods. It is recommended to change the oil when one half of new oil TBN with either method is reached.For example, new oil with a TBN of 10 by "ASTM D2896" should be changed when, during use, the TBN deteriorates to 5 as determined by the "ASTM D2896" test method. New oil with a TBN of 10 by "ASTM D4739" should be changed when, during use, the TBN deteriorates to 5 as determined by the "ASTM D4739" test method.Note: TBN is also commonly referred to as Base Number (BN).Excessive piston deposits can be produced by oil with a high TBN and/or high ash. These deposits can lead to a loss of control of the oil consumption and to the polishing of the cylinder bore.The use of Cat S O S Services oil analysis helps the environmental