Information injection-pump assembly

ZEXEL

104740-9900

1047409900

NISSAN-DIESEL

1670022T02

1670022t02

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-9900 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1121 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 9.8(100) |

| 10. | NOZZLE-HOLDER | 105078-0050 |

| 11. | NOZZLE | 105007-1130 |

Include in #2:

104740-9900

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

104740-9900

1047409900

NISSAN-DIESEL

1670022T02

1670022t02

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.2

51.7

52.7

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

10.1

5.6

14.6

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

33

30.5

35.5

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

42.9

40.8

45

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.2

51.2

53.2

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

52.8

50.8

54.8

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

33

31

35

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.3

5.3

9.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

7.3

5.3

9.3

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

258

522

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

489

360

618

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T ON

kPa

618

579

657

Pressure with S/T ON

kgf/cm2

6.3

5.9

6.7

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

598.5

569

628

Pressure with S/T OFF

kgf/cm2

6.1

5.8

6.4

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.3

3.9

4.7

Timer stroke with S/T OFF

mm

2.6

2.4

2.8

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.3

3.8

4.8

Timer stroke with S/T OFF

mm

2.6

2.3

2.9

_03

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T OFF

mm

4.9

4.3

5.5

_04

Pump speed

r/min

2550

2550

2550

Timer stroke with S/T OFF

mm

7.3

6.8

7.8

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

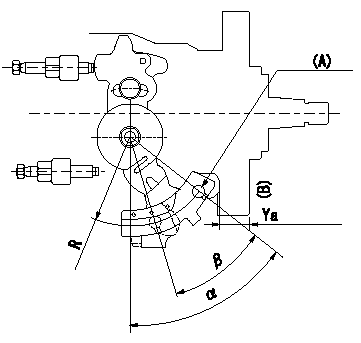

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle measuring position

(B) = flange face

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

Information:

Table 2

Specifications for Pressure Loss

Direct Injection Fuel Systems

Nozzle pressure must not drop below a gauge reading of

3450 kPa (500 psi) during a 5 second time interval.

Nozzle pressure must drop below a gauge reading of

1380 kPa (200 psi) after an additional 25 second time interval. (1)

( 1 ) A gauge reading of 0 kPa (0 psi) is acceptable after the first 5 second time interval has elapsed.

Illustration 3 g00923167

If the fuel nozzle is not within specifications, stop the test and do not use the fuel nozzle.Valve Opening Pressure Test

Slowly increase the pressure until fluid begins to flow from the tip of the fuel nozzle. Record this pressure as the VOP of the fuel nozzle.

Compare the test results to the specifications for the type of fuel nozzle that is being tested. Refer to Table 3, or Table 4.For precombustion chamber fuel systems, use these specifications:

Table 3

Specifications for Valve Opening Pressure

Precombustion Chamber Fuel Systems

2760 to 5170 kPa (400 to 750 psi)

Illustration 4 g00934108

If the VOP is not within specifications, stop the test and do not use the fuel nozzle.For direct injection fuel systems, use these specifications:

Table 4

Specifications for Valve Opening Pressure

Direct Injection Fuel Systems

16500 to 21400 kPa (2400 to 3100 psi)

Illustration 5 g00923174

If the VOP is not within specifications, stop the test and do not use the fuel nozzle.Tip Leakage Test (Direct Injection Fuel Systems)

Note: Fuel nozzles for precombustion chamber fuel systems can not be tested for tip leakage accurately. Do not perform this test on fuel nozzles for a precombustion