Information injection-pump assembly

ZEXEL

104740-9830

1047409830

NISSAN-DIESEL

1670021T06

1670021t06

Rating:

Cross reference number

ZEXEL

104740-9830

1047409830

NISSAN-DIESEL

1670021T06

1670021t06

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

44.1

45.1

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

8.85

5.3

12.4

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

27.8

32.8

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

38

35.9

40.1

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

43.6

45.6

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

43.5

41.5

45.5

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

28.3

32.3

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Governor adjustment_03

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

2

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T OFF

cm3/min

390

258

522

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T OFF

cm3/min

489

360

618

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1700

1700

1700

Pressure with S/T ON

kPa

618

579

657

Pressure with S/T ON

kgf/cm2

6.3

5.9

6.7

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T ON

kPa

618

579

657

Pressure with S/T ON

kgf/cm2

6.3

5.9

6.7

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

598.5

569

628

Pressure with S/T OFF

kgf/cm2

6.1

5.8

6.4

0000001101

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T ON

mm

6.2

5.8

6.6

Timer stroke with S/T OFF

mm

4.6

4.4

4.8

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T OFF

mm

2.5

2.1

2.9

_03

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T ON

mm

6.2

5.7

6.7

Timer stroke with S/T OFF

mm

4.6

4.3

4.9

_04

Pump speed

r/min

2550

2550

2550

Timer stroke with S/T OFF

mm

6.9

6.4

7.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

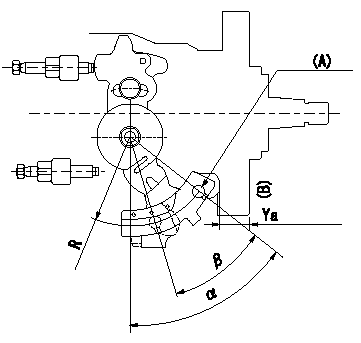

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle measuring position

(B) = flange face

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

Information:

Touchscreen Serial Port Usage

The optional touchscreen controller for a monitor connects internally to the "COM2" serial port. The touchscreen is configured at the factory with the proper "COM2" and touchscreen driver settings. Therefore, no configuration by the user is required. If the settings are corrupted, reset the "COM2" serial port to the following settings:

9600 bps

8 data bits

1 stop bit

no parityDriver Software

The touchscreen driver is already loaded on the monitor. The driver software is also provided on a floppy disk.Note: The Elo TouchSystems touchscreen utility defaults to the "COM1" serial port setting. Change the setting to the "COM2" serial port when the touchscreen driver is reinstalled.Resistive Touchsceen Technology

Resistive touchscreens are activated when pressure is applied to the touchscreen by the finger of an operator. You can operate a resistive touchsceen while you wear gloves.Note: Do not use sharp instruments to activate the touchscreen. Scratching the surface of the touchscreen could damage the unit.Resistive touchscreens consist of the following layers:

A lower layer (glass substrate) with a resistive coating and an applied voltage

An upper layer (cover sheet) with conductive coating

Clear spacer dots separate the two layers.The upper layer is pressed onto the lower layer by the user. The upper layer receives the voltage that is applied to the lower layer. The touchscreen controller detects the change in voltage on the upper layer. The touchscreen controller alternates the voltage horizontally through the layers. The touchscreen controller alternates the voltage vertically through the layers. The voltage that is transferred to the upper layer is proportional to the location of the touch on the screen.Calibrating the Touchscreen

The touchscreen that is supplied with the monitor is factory installed and calibrated. If the touchscreen needs to be recalibrated, perform the following procedure:

Locate the Elo calibration utility in the Control Panel or insert the touchscreen driver diskette in the floppy disk drive of the monitor.

Run the Elo calibration utility. Use appropriate commands for the operating system.

Follow the instructions in the Elo calibration utility in order to complete the calibration process.Maintenance

Routine Cleaning

Clean the surface of the touchscreen with any glass cleaning solution. Use a cloth that is soft and non-abrasive.Note: Because the touchscreen is sensitive to pressure, directing strong flow of water at the touchscreen during a washdown may activate the touchscreen.

The optional touchscreen controller for a monitor connects internally to the "COM2" serial port. The touchscreen is configured at the factory with the proper "COM2" and touchscreen driver settings. Therefore, no configuration by the user is required. If the settings are corrupted, reset the "COM2" serial port to the following settings:

9600 bps

8 data bits

1 stop bit

no parityDriver Software

The touchscreen driver is already loaded on the monitor. The driver software is also provided on a floppy disk.Note: The Elo TouchSystems touchscreen utility defaults to the "COM1" serial port setting. Change the setting to the "COM2" serial port when the touchscreen driver is reinstalled.Resistive Touchsceen Technology

Resistive touchscreens are activated when pressure is applied to the touchscreen by the finger of an operator. You can operate a resistive touchsceen while you wear gloves.Note: Do not use sharp instruments to activate the touchscreen. Scratching the surface of the touchscreen could damage the unit.Resistive touchscreens consist of the following layers:

A lower layer (glass substrate) with a resistive coating and an applied voltage

An upper layer (cover sheet) with conductive coating

Clear spacer dots separate the two layers.The upper layer is pressed onto the lower layer by the user. The upper layer receives the voltage that is applied to the lower layer. The touchscreen controller detects the change in voltage on the upper layer. The touchscreen controller alternates the voltage horizontally through the layers. The touchscreen controller alternates the voltage vertically through the layers. The voltage that is transferred to the upper layer is proportional to the location of the touch on the screen.Calibrating the Touchscreen

The touchscreen that is supplied with the monitor is factory installed and calibrated. If the touchscreen needs to be recalibrated, perform the following procedure:

Locate the Elo calibration utility in the Control Panel or insert the touchscreen driver diskette in the floppy disk drive of the monitor.

Run the Elo calibration utility. Use appropriate commands for the operating system.

Follow the instructions in the Elo calibration utility in order to complete the calibration process.Maintenance

Routine Cleaning

Clean the surface of the touchscreen with any glass cleaning solution. Use a cloth that is soft and non-abrasive.Note: Because the touchscreen is sensitive to pressure, directing strong flow of water at the touchscreen during a washdown may activate the touchscreen.