Information injection-pump assembly

ZEXEL

104740-9820

1047409820

NISSAN-DIESEL

1670021T05

1670021t05

Rating:

Cross reference number

ZEXEL

104740-9820

1047409820

NISSAN-DIESEL

1670021T05

1670021t05

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

44.1

45.1

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

8.85

5.3

12.4

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

27.8

32.8

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

38

35.9

40.1

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

43.6

45.6

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

43.5

41.5

45.5

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

28.3

32.3

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Governor adjustment_03

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

258

522

Stop lever angle

Pump speed

r/min

1700

1700

1700

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

431.5

402

461

Pressure

kgf/cm2

4.4

4.1

4.7

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

578.5

549

608

Pressure

kgf/cm2

5.9

5.6

6.2

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure

kPa

676.5

647

706

Pressure

kgf/cm2

6.9

6.6

7.2

0000001101

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

4.6

4.4

4.8

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

2.5

2.1

2.9

_03

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

4.6

4.3

4.9

_04

Pump speed

r/min

2550

2550

2550

Timer stroke

mm

6.9

6.4

7.4

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

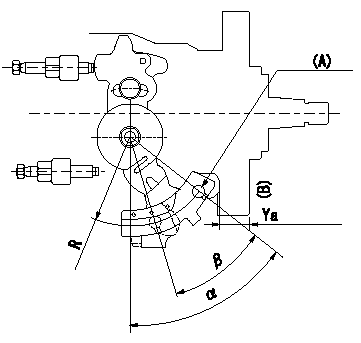

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle measuring position

(B) = flange face

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

Information:

- Generator Monitoring SystemI/O - Input/OutputMMS - Marine Monitoring SystemMMS II - Marine Monitoring System IIPLC - Programmable Logic ControllerThe 203-7811 Engine Monitoring Control Group is the service replacement for the 146-3117 Monitoring Control and the 162-1662 Monitoring Control that are used in MMS. The 203-7811 Engine Monitoring Control Group uses Wonderware as the "Graphic Display Application".The 203-7810 Engine Monitoring Control Group is the optional monitor that is used in the MMS II and the GMS. The 203-7810 Engine Monitoring Control Group uses the RSView as the "Graphic Display Application".When these engine monitoring control groups are used as service replacements in the field, use the procedure that follows to register the software to the user. This procedure can be done when the engine monitoring control group is connected to the PLC. This procedure can also be done when the engine monitoring control group is not connected to the PLC.

Connect a keyboard that is compatible with the PS/2 style of connector. Connect electrical power to the monitor.

Turn on the power.

When you are prompted, accept the license agreement. Press the "Next" button.

Enter the Microsoft Windows NT product identification number. This number is located on the right side of the computer. Press "Next".

When the message indicates that the system could not complete the login, select "OK".

Input "Administrator" for the login username. Input "3600" for the login password.

After a successful login as "Administrator", do one of the items that follow:

Restart the computer.

Close all of the programs and use a different login username.

When the message indicates that the system could not complete the login, select "OK".

Input "Operator" for the login username. Input "password" for the login password.

After a successful login as "Operator", one of the items that follow will occur:

If a 203-7811 Engine Monitoring Control Group is used, the Wonderware I/O Server and the Window Viewer will be started.

If a 203-7810 Engine Monitoring Control Group is used, the RSView Runtime will be started.

Remove the keyboard. The setup is complete.In applications that use Wonderware or RSView, the engine monitoring control group must be connected to the PLC in order for the data to be displayed.After a successful login to the "Operator" account, the computer will automatically start and the computer will start the application in the "Operator" account. The automatic start-up can be bypassed by doing the operations that follow:

Attach a keyboard.

Hold the "shift" key in the down position while the start-up of the computer is initiated.

Connect a keyboard that is compatible with the PS/2 style of connector. Connect electrical power to the monitor.

Turn on the power.

When you are prompted, accept the license agreement. Press the "Next" button.

Enter the Microsoft Windows NT product identification number. This number is located on the right side of the computer. Press "Next".

When the message indicates that the system could not complete the login, select "OK".

Input "Administrator" for the login username. Input "3600" for the login password.

After a successful login as "Administrator", do one of the items that follow:

Restart the computer.

Close all of the programs and use a different login username.

When the message indicates that the system could not complete the login, select "OK".

Input "Operator" for the login username. Input "password" for the login password.

After a successful login as "Operator", one of the items that follow will occur:

If a 203-7811 Engine Monitoring Control Group is used, the Wonderware I/O Server and the Window Viewer will be started.

If a 203-7810 Engine Monitoring Control Group is used, the RSView Runtime will be started.

Remove the keyboard. The setup is complete.In applications that use Wonderware or RSView, the engine monitoring control group must be connected to the PLC in order for the data to be displayed.After a successful login to the "Operator" account, the computer will automatically start and the computer will start the application in the "Operator" account. The automatic start-up can be bypassed by doing the operations that follow:

Attach a keyboard.

Hold the "shift" key in the down position while the start-up of the computer is initiated.