Information injection-pump assembly

ZEXEL

104740-9810

1047409810

NISSAN-DIESEL

1670021T04

1670021t04

Rating:

Cross reference number

ZEXEL

104740-9810

1047409810

NISSAN-DIESEL

1670021T04

1670021t04

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

44.1

45.1

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

8.9

5.4

12.4

Injection timing adjustment_03

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

27.8

32.8

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

38

35.9

40.1

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

44.6

43.6

45.6

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

43.5

41.5

45.5

Injection quantity adjustment

Pump speed

r/min

2350

2350

2350

Average injection quantity

mm3/st.

30.3

28.3

32.3

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Governor adjustment_03

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

390

258

522

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

489

360

618

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T ON

kPa

618

579

657

Pressure with S/T ON

kgf/cm2

6.3

5.9

6.7

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

598.5

569

628

Pressure with S/T OFF

kgf/cm2

6.1

5.8

6.4

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.2

3.8

4.6

Timer stroke with S/T OFF

mm

2.5

2.3

2.7

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.2

3.7

4.7

Timer stroke with S/T OFF

mm

2.5

2.2

2.8

_03

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T ON

mm

6.2

5.4

7

Timer stroke with S/T OFF

mm

4.6

4

5.2

_04

Pump speed

r/min

2550

2550

2550

Timer stroke with S/T OFF

mm

6.9

6.4

7.4

0000001201

Max. applied voltage

V

16

16

16

Test voltage

V

25

24

26

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

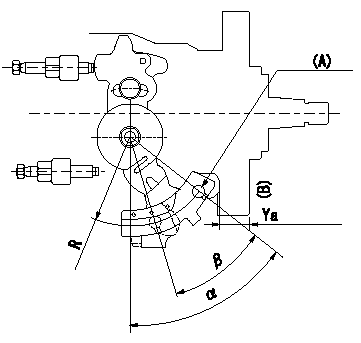

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle measuring position

(B) = flange face

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

Information:

Disconnect all electrical power from the panel before making a panel cutout. Make sure the area around the panel cutout is clear. Take precautions to prevent metal cuttings from entering any components that are already installed in the panel. Failure to follow these instructions may result in personal injury or damage to the panel components.

Environmental Considerations

Mount the monitor in a panel or in an enclosure in order to protect the internal circuitry.Provide adequate ventilation in the enclosure. Also, consider heat produced by other devices in the enclosure. The ambient temperature around the monitor must be maintained between 5 °C (41 °F) and 50 °C (122 °F). Make sure that you provide provisions for accessing the back panel and side panels of the monitor. Installing components and removing components requires access to the panels. The floppy disk drive is also accessed through the panels. Refer to Illustration 1.

Illustration 1 g00857541

Mounting ClearancesNote: The dimensions in Illustration 1 are only applicable if the monitor has adequate ventilation. Cooling methods must be used in order to lower air temperature within the enclosure.Mounting Hardware

Table 1

Item Description Quantity Use For

Self-locking nuts #10-32 10 (8 required) Panel or enclosure mounting In addition to the tools that are required in order to make the cut for the panel, you will need the following tools:

Drill

9.525 mm (3/8 inch) socket

15 cm (6 inch) extension rod (minimum)

Socket driver (in/lb. torque wrench recommended)

RulerPanel Mounting

In order to install the monitor in a panel, perform the following procedure:

Cut an opening in the panel by using the dimensions that are provided. Drill eight 6.4 mm (0.25 inch) holes for the mounting studs. Refer to Installation, "Dimensions" for more information.

Make sure that the sealing gasket is properly positioned on the terminal. This gasket forms a compression seal. Do not use sealing compounds.

Place the monitor in the opening in the panel. Align the studs with the mounting holes.

Install the eight self-locking nuts. Hand tighten the self-locking nuts.

Illustration 2 g00857579

Torque Sequence

Alternately tighten the self-locking nuts with the 9.525 mm (3/8 inch) socket. Tighten the nuts until the monitor is held firmly against the panel. The amount of torque that is required increases significantly as the gasket reaches the proper compression. Tighten the nuts to a torque of 2.7 N m (24 lb in). Refer to Illustration 2 for the recommended tightening sequence.Note: Tighten the nuts to a torque of 2.7 N m (24 lb in) in order to provide a proper seal and prevent damage to the monitor.