Information injection-pump assembly

ZEXEL

104740-8800

1047408800

Rating:

Cross reference number

ZEXEL

104740-8800

1047408800

Zexel num

Bosch num

Firm num

Name

104740-8800

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

1576414020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

52.1

53.1

Difference in delivery

mm3/st.

4

Basic

*

Remarks

NA

NA

Injection timing adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

59

58.5

59.5

Difference in delivery

mm3/st.

4.5

Basic

*

Remarks

CBS

CBS

Injection timing adjustment_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

65.9

65.4

66.4

Difference in delivery

mm3/st.

5.5

Basic

*

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

24.4

31.4

Injection timing adjustment_05

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

54.7

52.2

57.2

Injection timing adjustment_06

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

61.3

57.8

64.8

Injection timing adjustment_07

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

65.9

64.9

66.9

Injection timing adjustment_08

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

64.7

62.2

67.2

Injection timing adjustment_09

Pump speed

r/min

750

750

750

Boost pressure

kPa

33.35

32

34.7

Boost pressure

mmHg

250

240

260

Average injection quantity

mm3/st.

59

58

60

Injection timing adjustment_10

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

52.6

51.6

53.6

Injection quantity adjustment

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

27.9

24.9

30.9

Difference in delivery

mm3/st.

8.5

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

3050

3050

3050

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

16.4

14.9

17.9

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

5

Governor adjustment_03

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

16.4

14.4

18.4

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

75

65

85

Basic

*

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity

cm3/min

420

288

552

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

549.5

520

579

Pressure

kgf/cm2

5.6

5.3

5.9

Basic

*

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

549.5

520

579

Pressure

kgf/cm2

5.6

5.3

5.9

Stop lever angle_03

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

608

579

637

Pressure

kgf/cm2

6.2

5.9

6.5

Stop lever angle_04

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

735.5

706

765

Pressure

kgf/cm2

7.5

7.2

7.8

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.4

4.8

Basic

*

_02

Pump speed

r/min

500

500

500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

0.9

0.2

1.6

_03

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.5

2.9

4.1

_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

4.6

4.3

4.9

_05

Pump speed

r/min

1500

1500

1500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

5.6

5

6.2

_06

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

7.5

6.9

8.1

_07

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

7.7

7.2

8.2

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.9

56.4

57.4

Timer stroke variation dT

mm

0.7

0.5

0.9

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

56.9

55.9

57.9

Timer stroke variation dT

mm

0.7

0.4

1

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

43

41.5

44.5

Timer stroke variation dT

mm

2.1

1.6

2.6

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.4

1.3

1.5

BCS stroke

mm

3.2

3

3.4

Control lever angle alpha

deg.

55

51

59

Control lever angle beta

deg.

41

36

46

Test data Ex:

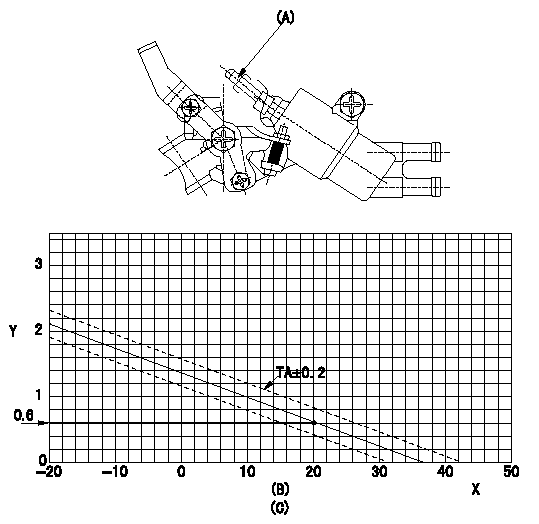

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the following graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(B): Timer stroke TA (mm):

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

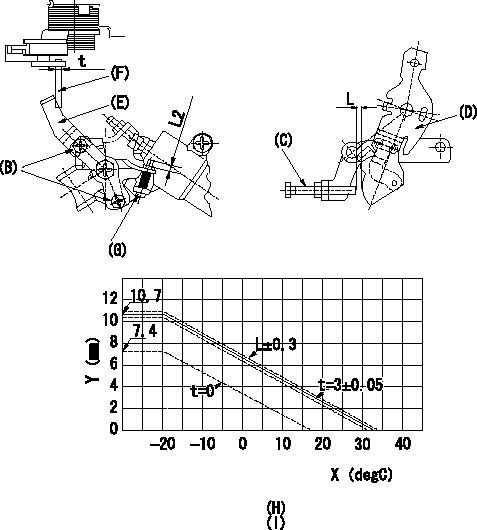

0000001901 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L1 determined from the graph below between the control lever (D) and the idling stopper bolt (C).

(2)Insert a shim t between the W-FICD lever (E) and the control lever (F). Adjust the W-FICD lever (E) so that it contacts the control lever (F) and fix it using bolt (B).

TT

Note:

a) The temperature of wax at the time of adjustment must not exceed a.

b) After completion of the adjustment, confirm that allowance for adjustment of the screw (G) is at least L2.

X = temperature (deg C)

Y = control lever dimension L (control lever position)

----------

L1=L+-0.05mm t=3+-0.05mm T=3.4~4.9Nm{0.35~0.5kgfm} L2=3mm a=30degC

----------

t=3mm (I):L=-0.201X+6.65(-20<=X(degC))(t=3+-0.05)

----------

L1=L+-0.05mm t=3+-0.05mm T=3.4~4.9Nm{0.35~0.5kgfm} L2=3mm a=30degC

----------

t=3mm (I):L=-0.201X+6.65(-20<=X(degC))(t=3+-0.05)

Information:

4C4911 Battery Load Tester

4C4911 Battery Load TesterThe 4C4911 Battery Load Tester is a portable unit in a metal case for use under field conditions and high temperatures. It can be used to load test all 6, 8 and 12V batteries. This tester has two heavy-duty load cables that can easily be fastened to the battery terminals, and a load adjustment knob on the top permits the current being drawn from the battery to be adjusted to a maximum of 1000 amperes. The tester is cooled by an internal fan that is automatically activated when a load is applied.The tester has a built in Liquid Crystal Display (LCD) digital voltmeter and amperage meter. The digital voltmeter accurately measures the battery voltage at the battery, through tracer wires buried inside the load cables. The digital amperage meter accurately displays the current being drawn from the battery under test. Make reference to Operating Manual, SEHS9249 for more complete information for use of the 4C4911 Battery Load Tester.8T0900 AC/DC Clamp-On Ammeter

8T0900 AC/DC Clamp-On AmmeterThe 8T0900 AC/DC Clamp-On Ammeter is a completely portable, self-contained instrument that allows electrical current measurements to be made without breaking the circuit or disturbing the insulation on conductors. A digital display is located on the ammeter for reading current directly in a range from 1 to 1200 amperes. If an optional 6V6014 Cable is connected between this ammeter and one of the digital multimeters, current readings of less than 1 ammeter can then be read directly from the display of the multimeter.A lever is used to open the jaws over the conductor [up to a diameter of 19 mm (.75 in)], and the spring loaded jaws are then closed around the conductor for current measurement. A trigger switch that can be locked in the ON or OFF position is used to turn on the ammeter. When the turn-on trigger is released, the last current reading is held on the display for five seconds. This allows accurate measurements to be taken in limited access areas where the digital display is not visible to the operator. A zero control is provided for DC operation, and power for the ammeter is supplied by batteries located inside the handle. Make reference to Special Instruction, SEHS8420 for more complete information for use of the 8T0900 Clamp-On Ammeter.6V7070 Heavy-Duty Digital Multimeter

6V7070 Heavy-Duty Digital MultimeterThe 6V7070 Heavy-Duty Digital Multimeter is a completely portable, hand held instrument with a digital display. This multimeter is built with extra protection against damage in field applications, and is equipped with seven functions and 29 ranges. The 6V7070 Multimeter has an instant ohms indicator that permits continuity checking for fast circuit inspection. It also can be used for troubleshooting small value capacitors.The 6V7800 Regular-duty Digital Multimeter (a low cost option to the Heavy-Duty Multimeter) is also available; however, the 6V7800 Multimeter does not have the 10A range or the instant ohms feature of the 6V7070 Multimeter. Make reference to Special Instruction, SEHS7734 for more complete information for use of the

4C4911 Battery Load TesterThe 4C4911 Battery Load Tester is a portable unit in a metal case for use under field conditions and high temperatures. It can be used to load test all 6, 8 and 12V batteries. This tester has two heavy-duty load cables that can easily be fastened to the battery terminals, and a load adjustment knob on the top permits the current being drawn from the battery to be adjusted to a maximum of 1000 amperes. The tester is cooled by an internal fan that is automatically activated when a load is applied.The tester has a built in Liquid Crystal Display (LCD) digital voltmeter and amperage meter. The digital voltmeter accurately measures the battery voltage at the battery, through tracer wires buried inside the load cables. The digital amperage meter accurately displays the current being drawn from the battery under test. Make reference to Operating Manual, SEHS9249 for more complete information for use of the 4C4911 Battery Load Tester.8T0900 AC/DC Clamp-On Ammeter

8T0900 AC/DC Clamp-On AmmeterThe 8T0900 AC/DC Clamp-On Ammeter is a completely portable, self-contained instrument that allows electrical current measurements to be made without breaking the circuit or disturbing the insulation on conductors. A digital display is located on the ammeter for reading current directly in a range from 1 to 1200 amperes. If an optional 6V6014 Cable is connected between this ammeter and one of the digital multimeters, current readings of less than 1 ammeter can then be read directly from the display of the multimeter.A lever is used to open the jaws over the conductor [up to a diameter of 19 mm (.75 in)], and the spring loaded jaws are then closed around the conductor for current measurement. A trigger switch that can be locked in the ON or OFF position is used to turn on the ammeter. When the turn-on trigger is released, the last current reading is held on the display for five seconds. This allows accurate measurements to be taken in limited access areas where the digital display is not visible to the operator. A zero control is provided for DC operation, and power for the ammeter is supplied by batteries located inside the handle. Make reference to Special Instruction, SEHS8420 for more complete information for use of the 8T0900 Clamp-On Ammeter.6V7070 Heavy-Duty Digital Multimeter

6V7070 Heavy-Duty Digital MultimeterThe 6V7070 Heavy-Duty Digital Multimeter is a completely portable, hand held instrument with a digital display. This multimeter is built with extra protection against damage in field applications, and is equipped with seven functions and 29 ranges. The 6V7070 Multimeter has an instant ohms indicator that permits continuity checking for fast circuit inspection. It also can be used for troubleshooting small value capacitors.The 6V7800 Regular-duty Digital Multimeter (a low cost option to the Heavy-Duty Multimeter) is also available; however, the 6V7800 Multimeter does not have the 10A range or the instant ohms feature of the 6V7070 Multimeter. Make reference to Special Instruction, SEHS7734 for more complete information for use of the

Have questions with 104740-8800?

Group cross 104740-8800 ZEXEL

104740-8800

INJECTION-PUMP ASSEMBLY