Information injection-pump assembly

BOSCH

9 460 610 638

9460610638

ZEXEL

104740-8780

1047408780

MITSUBISHI

MD306842

md306842

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104740-8780 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 104640-8780 |

| 3. | NUMBER PLATE | 146954-4500 |

| 4. | _ | |

| 5. | CAPSULE | 146620-0120 |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105148-1112 |

| 8. | Nozzle and Holder | MD103301 |

| 9. | Open Pre:MPa(Kqf/cm2) | 11.8{120} |

| 10. | NOZZLE-HOLDER | 105078-0012 |

| 11. | NOZZLE | 105007-1120 |

Scheme ###:

| 1/6. | [1] | 146601-0700 | PACKING RING |

| 6. | [1] | 146100-0120 | SUPPLY PUMP |

| 9. | [1] | 146103-0000 | COVER |

| 10. | [2] | 139104-0000 | FLAT-HEAD SCREW |

| 12. | [1] | 146200-0320 | DRIVE SHAFT |

| 12/1. | [1] | 146200-0300 | DRIVE SHAFT |

| 12/2. | [1] | 146201-0000 | WOODRUFF KEY |

| 12/3. | [2] | 146202-0100 | DAMPER |

| 12/4. | [1] | 146203-0000 | TOOTHED GEAR |

| 17. | [1] | 146204-0000 | PLAIN WASHER |

| 20. | [1] | 146210-4120 | ROLLER SET |

| 24. | [1] | 146303-0100 | BEARING PIN |

| 25. | [1] | 146304-0000 | BEARING PIN |

| 26. | [1] | 146305-0000 | CLAMPING BAND |

| 27. | [1] | 146205-0000 | SLOTTED WASHER |

| 29. | [1] | 146220-2120 | CAM PLATE |

| 30. | [1] | 146600-0800 | O-RING |

| 31. | [1] | 146300-2400 | PUMP PLUNGER |

| 32. | [1] | 146301-0000 | SLIDING PIECE |

| 33. | [1] | 146603-0700 | SHIM |

| 34. | [1] | 146302-3600 | COMPRESSION SPRING |

| 34B. | [1] | 146302-3500 | COMPRESSION SPRING |

| 34C. | [1] | 146302-3700 | COMPRESSION SPRING |

| 35/1. | [0] | 146603-0700 | SHIM D17.5&7.5T0.60 |

| 35/1. | [0] | 146603-0800 | SHIM D17.5&7.5T0.70 |

| 35/1. | [0] | 146603-0900 | SHIM D17.5&7.5T0.90 |

| 35/1. | [0] | 146603-1000 | SHIM D17.5&7.5T1.00 |

| 35/1. | [0] | 146603-1100 | SHIM D17.5&7.5T1.20 |

| 35/1. | [0] | 146603-3600 | SHIM D17.5&7.5T2.40 |

| 36. | [1] | 146600-0800 | O-RING |

| 37. | [1] | 146310-0700 | COVER |

| 38. | [2] | 146620-5000 | BLEEDER SCREW |

| 39. | [1] | 146310-0100 | COVER |

| 40. | [2] | 146620-5000 | BLEEDER SCREW |

| 43. | [1] | 146230-0000 | SHIM |

| 44. | [1] | 146230-0100 | PLAIN WASHER |

| 45. | [1] | 146231-0001 | SLOTTED WASHER |

| 47. | [2] | 146233-0000 | SLOTTED WASHER |

| 48/1. | [1] | 146603-0100 | SHIM D17.0&5.2T0.80 |

| 48/1. | [1] | 146603-0200 | SHIM D17.0&5.2T1.00 |

| 48/1. | [1] | 146603-0300 | SHIM D17.0&5.2T1.20 |

| 48/1. | [1] | 146603-0400 | SHIM D17.0&5.2T1.50 |

| 48/1. | [1] | 146690-1400 | SHIM D17&5.2T0.9 |

| 48/1. | [1] | 146690-1500 | SHIM D17&5.2T1.1 |

| 48/1. | [1] | 146690-1600 | SHIM D17&5.2T1.3 |

| 48/1. | [1] | 146690-1700 | SHIM D17&5.2T1.4 |

| 48/1. | [1] | 146690-1800 | SHIM D17&5.2T1.6 |

| 49. | [2] | 146234-0500 | GUIDE PIN |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 50. | [1] | 146401-0221 | HYDRAULIC HEAD |

| 51. | [1] | 146600-0000 | O-RING |

| 52/1. | [1] | 146420-0200 | SHIM D9.5&3.0T1.94 |

| 52/1. | [1] | 146420-0700 | SHIM D9.5&3.0T2.04 |

| 52/1. | [1] | 146420-1200 | SHIM D9.5&3.0T2.14 |

| 52/1. | [1] | 146420-1700 | SHIM D9.5&3.0T2.24 |

| 52/1. | [1] | 146420-2200 | SHIM D9.5&3.0T2.34 |

| 52/1. | [1] | 146420-2700 | SHIM D9.5&3.0T2.44 |

| 52/1. | [1] | 146420-3200 | SHIM D9.5&3.0T2.54 |

| 52/1. | [1] | 146420-3700 | SHIM D9.5&3.0T2.64 |

| 52/1. | [1] | 146420-5600 | SHIM D9.5&3.0T1.84 |

| 54. | [4] | 146433-0100 | GASKET |

| 55. | [4] | 146430-0320 | DELIVERY-VALVE ASSEMBLY VE4 |

| 56. | [4] | 146432-0000 | COMPRESSION SPRING |

| 58. | [4] | 146440-0320 | FITTING |

| 60. | [3] | 139106-0100 | FLAT-HEAD SCREW |

| 67. | [1] | 146820-2320 | GOVERNOR COVER |

| 67/1. | [1] | 146508-8221 | GOVERNOR COVER |

| 67/2. | [1] | 146515-0320 | CONTROL SHAFT |

| 67/3. | [1] | 146600-0100 | O-RING |

| 67/4. | [1] | 139310-0200 | PLAIN WASHER |

| 67/13. | [1] | 146621-1700 | UNION NUT |

| 67/14. | [1] | 146621-1700 | UNION NUT |

| 67/15. | [1] | 146526-3400 | BLEEDER SCREW |

| 67/16. | [1] | 146526-2800 | BLEEDER SCREW |

| 67/78. | [1] | 146600-4400 | SEAL RING |

| 67/200. | [1] | 139308-0300 | PLAIN WASHER |

| 67/201. | [1] | 146545-3400 | THREADED PIN L53.00 |

| 67/201B. | [1] | 146545-3500 | THREADED PIN L55.00 |

| 67/201C. | [1] | 146545-3600 | THREADED PIN L57.00 |

| 67/202. | [1] | 139208-0900 | UNION NUT |

| 67/203. | [1] | 146600-1200 | O-RING |

| 72. | [1] | 146830-7620 | CONTROL LEVER STAMP 30-76 |

| 72B. | [1] | 146830-7720 | CONTROL LEVER STAMP 30-77 |

| 73. | [1] | 014110-6440 | LOCKING WASHER D12.2&6.1T1.5 |

| 75. | [1] | 013020-6040 | UNION NUT |

| 95. | [1] | 146551-6120 | FULCRUM LEVER |

| 104. | [2] | 146568-0000 | SLOTTED SPRING PIN |

| 105. | [2] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 106. | [2] | 146588-0500 | COILED SPRING |

| 107. | [1] | 146569-0300 | UNION NUT |

| 108. | [1] | 146570-0420 | GOVERNOR SHAFT |

| 109. | [1] | 146600-0400 | O-RING |

| 110/1. | [1] | 146571-0000 | SHIM D20.2&8.3T1.05 |

| 110/1. | [1] | 146571-0100 | SHIM D20.2&8.3T1.25 |

| 110/1. | [1] | 146571-0200 | SHIM D20.2&8.3T1.45 |

| 110/1. | [1] | 146571-0300 | SHIM D20.2&8.3T1.65 |

| 110/1. | [1] | 146571-0400 | SHIM D20.2&8.3T1.85 |

| 111. | [1] | 146602-0600 | PLAIN WASHER |

| 112. | [1] | 146572-0020 | FLYWEIGHT ASSEMBLY |

| 114. | [1] | 146602-0500 | PLAIN WASHER |

| 115. | [1] | 146975-8000 | SLIDING SLEEVE |

| 116. | [1] | 146576-0000 | SEALING CAP |

| 117/1. | [1] | 146577-2200 | PLUG L2.90 |

| 117/1. | [1] | 146577-2300 | PLUG L3.10 |

| 117/1. | [1] | 146577-2400 | PLUG L3.30 |

| 117/1. | [1] | 146577-2500 | PLUG L3.50 |

| 117/1. | [1] | 146577-2600 | PLUG L3.70 |

| 117/1. | [1] | 146577-2700 | PLUG L3.90 |

| 117/1. | [1] | 146577-2800 | PLUG L4.10 |

| 117/1. | [1] | 146577-2900 | PLUG L4.30 |

| 117/1. | [1] | 146577-3000 | PLUG L4.50 |

| 117/1. | [1] | 146577-7100 | PLUG L3.0 |

| 117/1. | [1] | 146577-7200 | PLUG L3.2 |

| 117/1. | [1] | 146577-7300 | PLUG L3.4 |

| 117/1. | [1] | 146577-7400 | PLUG L3.6 |

| 117/1. | [1] | 146577-7500 | PLUG L3.8 |

| 117/1. | [1] | 146577-7600 | PLUG L4.0 |

| 117/1. | [1] | 146577-7700 | PLUG L4.2 |

| 117/1. | [1] | 146577-7800 | PLUG L4.4 |

| 120. | [1] | 146579-5320 | RETAINING PIN |

| 122. | [1] | 146580-2300 | GOVERNOR SPRING |

| 123. | [4] | 139106-0200 | FLAT-HEAD SCREW |

| 130. | [1] | 146421-0020 | CAPSULE |

| 130/2. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 130/3. | [1] | 146422-0000 | BLEEDER SCREW |

| 130/4. | [1] | 146600-0500 | O-RING |

| 133. | [1] | 146600-0600 | O-RING |

| 134. | [1] | 146600-0700 | O-RING |

| 135. | [1] | 146110-0220 | CONTROL VALVE STAMP 02 |

| 135/5. | [1] | 146114-0000 | SPRING WASHER |

| 136. | [1] | 146120-0020 | OVER FLOW VALVE |

| 137. | [2] | 139512-0500 | GASKET |

| 138. | [1] | 146605-8620 | INLET UNION |

| 200. | [1] | 146206-0100 | COILED SPRING |

| 205. | [1] | 029470-4030 | WOODRUFF KEY |

| 217. | [1] | 146542-5300 | SLOTTED WASHER |

| 218. | [1] | 146592-2500 | COILED SPRING |

| 219. | [1] | 146541-3000 | BUSHING |

| 220. | [1] | 146592-2600 | COILED SPRING |

| 224. | [1] | 139006-4700 | BLEEDER SCREW |

| 229. | [1] | 146928-1220 | BRACKET |

| 230. | [1] | 146629-2120 | BRACKET |

| 231. | [1] | 139006-4600 | BLEEDER SCREW |

| 232. | [1] | 146931-3200 | BRACKET STAMP 132 |

| 233. | [1] | 146658-9020 | WIRE |

| 234. | [1] | 139006-4800 | BLEEDER SCREW |

| 235. | [1] | 146659-0600 | CLAMPING BAND |

| 237. | [1] | 146620-0200 | HEX-SOCKET-HEAD CAP SCREW |

| 240. | [1] | 146650-1220 | PULLING ELECTROMAGNET |

| 240/8. | [1] | 146600-1700 | O-RING |

| 243. | [1] | 146621-1000 | UNION NUT |

| 245. | [2] | 139512-0500 | GASKET |

| 246. | [1] | 146125-0300 | EYE BOLT |

| 247. | [1] | 146666-0120 | INLET UNION |

| 253. | [1] | 139006-4500 | BLEEDER SCREW |

| 275. | [1] | 146612-4800 | BRACKET |

| 276. | [2] | 010010-1640 | BLEEDER SCREW |

| 280. | [0] | 146361-1920 | |

| 280. | [1] | 146361-7020 | START ADVANCE ASSY STAMP 119 |

| 281. | [1] | 146600-0800 | O-RING |

| 282. | [2] | 010206-1240 | HEX-SOCKET-HEAD CAP SCREW |

| 286. | [1] | 020106-3040 | BLEEDER SCREW |

| 287. | [1] | 014010-6140 | PLAIN WASHER D13&6.5T1.0 |

| 800S. | [1] | 146018-5120 | PUMP HOUSING |

| 800S/1/6. | [1] | 146601-0700 | PACKING RING |

| 804S. | [1] | 146232-0320 | COMPRESSION SPRING |

| 805S. | [1] | 146574-0120 | PARTS SET |

| 810S. | [1] | 146600-1120 | REPAIR SET |

| 821S. | [1] | 146210-5720 | ROLLER SET |

| 835S. | [1] | 146598-1000 | CAP |

| 836S/1. | [1] | 146598-0600 | CAP L18 |

| 836S/1. | [1] | 146598-0700 | CAP L21 |

| 836S/1. | [1] | 146598-0800 | CAP L24 |

| 836S/1. | [1] | 146598-0900 | CAP L27 |

| 903. | [1] | 146620-0120 | CAPSULE |

| 903/2. | [1] | 146600-1300 | O-RING |

| 906. | [1] | 146954-4500 | NAMEPLATE |

| 910S. | [1] | 146600-4020 | PARTS SET |

| 910S. | [1] | 146600-4020 | PARTS SET |

| 912S. | [1] | 026508-1140 | GASKET D11.4&8.2T1.0 |

| 913S. | [1] | 146422-0000 | BLEEDER SCREW |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 914S. | [1] | 146699-0020 | VALVE SET |

| 915S. | [1] | 146658-9020 | WIRE |

| 916S. | [1] | 025804-1610 | WOODRUFF KEY |

Include in #2:

104740-8780

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 460 610 638

9460610638

ZEXEL

104740-8780

1047408780

MITSUBISHI

MD306842

md306842

Zexel num

Bosch num

Firm num

Name

104740-8780

9 460 610 638

MD306842 MITSUBISHI

INJECTION-PUMP ASSEMBLY

4D56 K 11CJ INJECTION PUMP ASSY VE4 VE

4D56 K 11CJ INJECTION PUMP ASSY VE4 VE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

45.8

45.3

46.3

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

18.1

14.6

21.6

Injection timing adjustment_03

Pump speed

r/min

2100

2100

2100

Average injection quantity

mm3/st.

39.2

37.1

41.3

Injection timing adjustment_04

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

40.2

38.2

42.2

Injection timing adjustment_05

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

45.8

44.8

46.8

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

44.3

42.3

46.3

Injection quantity adjustment

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

18.1

15.1

21.1

Difference in delivery

mm3/st.

4

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2900

2900

2900

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

10

8.5

11.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

3

Governor adjustment_03

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

5

Governor adjustment_04

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

10

8

12

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

73

63

83

Basic

*

Remarks

IDLE

IDLE

Speed control lever angle

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Overflow quantity

cm3/min

420

288

552

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Stop lever angle_02

Pump speed

r/min

1250

1250

1250

Pressure

kPa

470.5

441

500

Pressure

kgf/cm2

4.8

4.5

5.1

Stop lever angle_03

Pump speed

r/min

2100

2100

2100

Pressure

kPa

666.5

637

696

Pressure

kgf/cm2

6.8

6.5

7.1

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.7

3.5

3.9

Basic

*

_02

Pump speed

r/min

500

500

500

Timer stroke

mm

1.2

0.6

1.8

_03

Pump speed

r/min

750

750

750

Timer stroke

mm

2

1.4

2.6

_04

Pump speed

r/min

1250

1250

1250

Timer stroke

mm

3.7

3.4

4

_05

Pump speed

r/min

1750

1750

1750

Timer stroke

mm

5.8

5.2

6.4

_06

Pump speed

r/min

2100

2100

2100

Timer stroke

mm

7.2

6.6

7.8

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.7

35.2

36.2

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

_02

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

35.7

34.7

36.7

Timer stroke variation dT

mm

0.6

0.3

0.9

_03

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

28.2

26.7

29.7

Timer stroke variation dT

mm

1.4

0.9

1.9

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1.2

1.1

1.3

Control lever angle alpha

deg.

55

51

59

Control lever angle beta

deg.

41

36

46

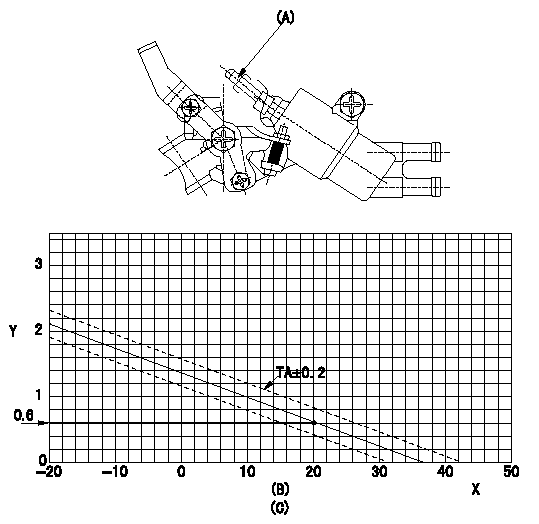

Test data Ex:

0000001801 W-CSD ADJUSTMENT

Adjustment of the W-CSD

1. Adjustment of the advance angle of the timer

(1)Determine the timer advance angle using the following graph.

(2)(1) Adjust with the screw (A) so that the timer advance angle determined in the item (1) is obtained.

X:Temperature t (deg C)

Y:Timer stroke TA (mm)

(B): Timer stroke TA (mm):

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

----------

----------

(C)=TA=-0.0376t+1.38(-20<=t)

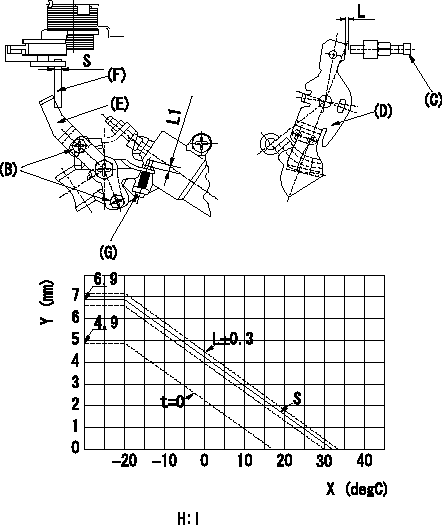

0000001901 W-FICD LEVER ADJUSTMENT

2. Adjustment of the W-FICD

(1)Insert a block gauge L2 determined from the graph below between the control lever (D) and the idling stopper bolt (C).

(2)Insert a shim S between the W-FICD lever (E) and the control lever (F). Adjust the W-FICD lever (E) so that it contacts the control lever (F) and fix it using bolt (B).

TT

Note:

a) The temperature of wax at the time of adjustment must not exceed a.

b) After completion of the adjustment, confirm that allowance for adjustment of the screw (G) is at least L1.

X:Temperature X (deg C)

Y:Control lever: dimension L (mm) (control lever position)

H:Graph, L - X graph

----------

L2=L+-0.05mm S=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

L1=3++mm S=(3mm) H:L=-0.132X+4.29(-20<=X)(S=3+-0.05)

----------

L2=L+-0.05mm S=3+-0.05mm T=3.4~4.9N-m(0.35~0.5kgf-m) a=30degC L1=3mm

----------

L1=3++mm S=(3mm) H:L=-0.132X+4.29(-20<=X)(S=3+-0.05)

Information:

Important Safety Information

Illustration 1 g02139237Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly. Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. If a tool, a procedure, a work method, or operating technique that is not recommended by Caterpillar is used, ensure that it is safe for you and for other people to use. Ensure that the product will not be damaged or the product will not be made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result in injury or death.Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons.The hazards are identified by the safety alert symbol which is followed by a signal word such as danger, warning, or caution. The "" safety alert symbol is shown below.

Illustration 2 g00008666This safety alert symbol means:Pay attention!Become alert!Your safety is involved.The message that appears under the safety alert symbol explains the hazard.Operations that may cause product damage are identified by "" labels on the product and in this publication.Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. The safety information in this document and the safety information on the machine are not all inclusive. Determine that the tools, procedures, work methods, and operating techniques are safe. Determine that the operation, lubrication, maintenance, and repair procedures will not damage the machine. Also, you must determine that the operation, lubrication, maintenance, and repair procedures will not make the machine unsafe.The information, the specifications, and the illustrations that exist in this guideline are based on information which was available at the time of publication. The specifications, torques, pressures, measurements, adjustments, illustrations, and other items can change at any time. These changes can affect the service that is given to the product. Obtain the complete, most current information before you start any job. Caterpillar dealers can supply the most current information.Summary

The information included in this guideline should serve as an aid in fuel injection pump housing test procedure.Service Letters and Technical Information Bulletins

The most recent Service Letters and Technical Information Bulletins

Illustration 1 g02139237Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools to perform these functions properly. Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive. If a tool, a procedure, a work method, or operating technique that is not recommended by Caterpillar is used, ensure that it is safe for you and for other people to use. Ensure that the product will not be damaged or the product will not be made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result in injury or death.Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons.The hazards are identified by the safety alert symbol which is followed by a signal word such as danger, warning, or caution. The "" safety alert symbol is shown below.

Illustration 2 g00008666This safety alert symbol means:Pay attention!Become alert!Your safety is involved.The message that appears under the safety alert symbol explains the hazard.Operations that may cause product damage are identified by "" labels on the product and in this publication.Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. The safety information in this document and the safety information on the machine are not all inclusive. Determine that the tools, procedures, work methods, and operating techniques are safe. Determine that the operation, lubrication, maintenance, and repair procedures will not damage the machine. Also, you must determine that the operation, lubrication, maintenance, and repair procedures will not make the machine unsafe.The information, the specifications, and the illustrations that exist in this guideline are based on information which was available at the time of publication. The specifications, torques, pressures, measurements, adjustments, illustrations, and other items can change at any time. These changes can affect the service that is given to the product. Obtain the complete, most current information before you start any job. Caterpillar dealers can supply the most current information.Summary

The information included in this guideline should serve as an aid in fuel injection pump housing test procedure.Service Letters and Technical Information Bulletins

The most recent Service Letters and Technical Information Bulletins

Have questions with 104740-8780?

Group cross 104740-8780 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

104740-8780

9 460 610 638

MD306842

INJECTION-PUMP ASSEMBLY

4D56

4D56