Information injection-pump assembly

ZEXEL

104740-8660

1047408660

MITSUBISHI

ME200202

me200202

Rating:

Cross reference number

ZEXEL

104740-8660

1047408660

MITSUBISHI

ME200202

me200202

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

With S/T O-ring; S/T OFF. OFF

With S/T O-ring; S/T OFF. OFF

Injection timing adjustment

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

62.7

62.2

63.2

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Injection timing adjustment_02

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

60.2

57.7

62.7

Oil temperature

degC

50

48

52

Injection timing adjustment_03

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

62.7

61.7

63.7

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_04

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

61.6

61.6

64.1

Oil temperature

degC

50

48

52

Injection timing adjustment_05

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

60.1

57.1

63.1

Oil temperature

degC

50

48

52

Injection quantity adjustment

Pump speed

r/min

2475

2475

2475

Average injection quantity

mm3/st.

30.5

27.5

33.5

Difference in delivery

mm3/st.

9

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_02

Pump speed

r/min

2475

2475

2475

Average injection quantity

mm3/st.

30.5

25.5

35.5

Difference in delivery

mm3/st.

9.5

Basic

*

Oil temperature

degC

52

50

54

Injection quantity adjustment_03

Pump speed

r/min

2800

2800

2800

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

6.3

10.3

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

8.3

5.8

10.8

Difference in delivery

mm3/st.

2.5

Basic

*

Oil temperature

degC

48

46

50

Timer adjustment

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

48

38

58

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

48

38

58

Basic

*

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

830

700

960

Overflow quantity with S/T OFF

cm3/min

910

780

1040

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Pressure with S/T ON

kPa

559

530

588

Pressure with S/T ON

kgf/cm2

5.7

5.4

6

Pressure with S/T OFF

kPa

471

451

491

Pressure with S/T OFF

kgf/cm2

4.8

4.6

5

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

700

700

700

Pressure with S/T ON

kPa

431

382

480

Pressure with S/T ON

kgf/cm2

4.4

3.9

4.9

Pressure with S/T OFF

kPa

314

265

363

Pressure with S/T OFF

kgf/cm2

3.2

2.7

3.7

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1000

1000

1000

Pressure with S/T ON

kPa

500

451

549

Pressure with S/T ON

kgf/cm2

5.1

4.6

5.6

Pressure with S/T OFF

kPa

412

373

451

Pressure with S/T OFF

kgf/cm2

4.2

3.8

4.6

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

1250

1250

1250

Pressure with S/T ON

kPa

559

520

598

Pressure with S/T ON

kgf/cm2

5.7

5.3

6.1

Pressure with S/T OFF

kPa

471

442

500

Pressure with S/T OFF

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_05

Pump speed

r/min

1500

1500

1500

Pressure with S/T ON

kPa

618

569

667

Pressure with S/T ON

kgf/cm2

6.3

5.8

6.8

Pressure with S/T OFF

kPa

530

481

579

Pressure with S/T OFF

kgf/cm2

5.4

4.9

5.9

Oil temperature

degC

50

48

52

Stop lever angle_06

Pump speed

r/min

2000

2000

2000

Pressure with S/T OFF

kPa

628

579

677

Pressure with S/T OFF

kgf/cm2

6.4

5.9

6.9

Oil temperature

degC

50

48

52

0000001101

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

4.4

4

4.8

Timer stroke with S/T OFF

mm

2.9

2.7

3.1

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

700

700

700

Timer stroke with S/T ON

mm

2

1.3

2.7

Timer stroke with S/T OFF

mm

0.8

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Timer stroke with S/T ON

mm

4.4

3.8

5

Timer stroke with S/T OFF

mm

2.9

2.5

3.3

Basic

*

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

2400

2400

2400

Timer stroke with S/T OFF

mm

7.4

6.9

7.8

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.9

0.8

1

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

42

37

47

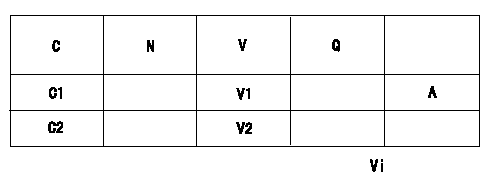

Test data Ex:

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Vi:Applied voltage

C:Position of the control lever

N:Pump speed

V:Output voltage

Q:Injection quantity

A:Adjusting point

C1:Idling

C2:Full speed

----------

----------

V1=1.6+-0.03(V) V2=(8.6(V)) Vi=10(V)

----------

----------

V1=1.6+-0.03(V) V2=(8.6(V)) Vi=10(V)

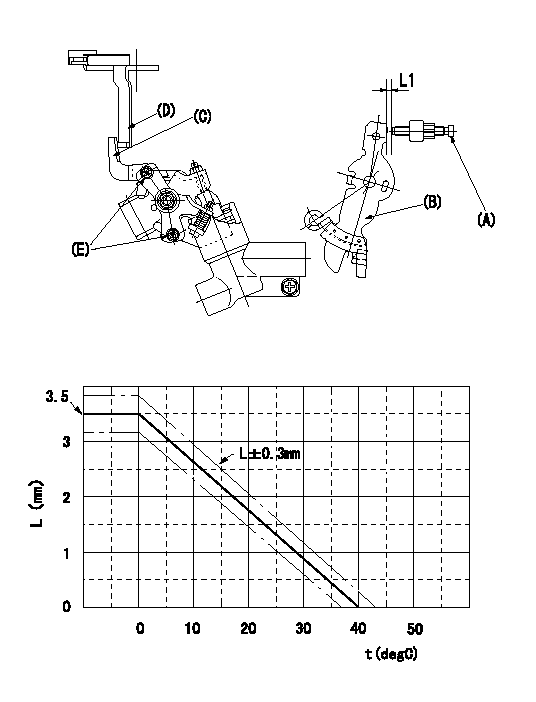

0000001901 W-FICD LEVER ADJUSTMENT

2. W-FICD (E) adjustment

(1)Insert a block gauge L1 determined from the graph between the control lever (B) and the idling set screw (A).

Graph for calculating L (mm) L = -0.088t+3.5

(2)Fix bolt (E) in the position where W-FICD lever (C) contacts the control lever (D). (Tighten to torque T.)

(3)The temperature of the wax at adjustment must not exceed a.

t:Temperature

L:Control lever L dimension (control lever position)

----------

L1=L+-0.3(mm) T=3.4~4.9(Nm)(0.35~0.5(kgfm)) a=35(degC)

----------

L1=L+-0.3(mm)

----------

L1=L+-0.3(mm) T=3.4~4.9(Nm)(0.35~0.5(kgfm)) a=35(degC)

----------

L1=L+-0.3(mm)

Information:

Recommended Procedure With Chassis Dynamometer

Possible Causes/Corrections Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. Refer to LEBV2810 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Make the necessary adjustments or repairs to the engine if needed.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner/Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.Recommended Procedure Without Chassis Dynamometer

Possible Causes/Corrections Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Fuel Injection Timing Not CorrectFollow the procedures in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceInstall the tooling and follow the procedure given in the Road Test section.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner/Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.

Possible Causes/Corrections Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceDo a Power Analysis Report (PAR), Level II, to check engine performance. Refer to LEBV2810 and SEHS7886 for the tooling and procedures to use. Be sure to make a record of the temperatures for inlet air, fuel (at filter base), lubricating oil and coolant. Make the necessary adjustments or repairs to the engine if needed.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner/Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.Recommended Procedure Without Chassis Dynamometer

Possible Causes/Corrections Minor Operating FaultsTo help identify a problem before a more involved troubleshooting procedure is started, follow the procedure given in the "Primary Engine Checks" section. Fuel Ratio Control Out Of Adjustment Or DefectiveFollow the procedure in the Testing and Adjusting Section of this Service Manual. Fuel Injection Timing Not CorrectFollow the procedures in the Testing and Adjusting Section of this Service Manual. Check Engine PerformanceInstall the tooling and follow the procedure given in the Road Test section.At this point, the governor fuel settings should be verified. See the Testing and Adjusting Section of this Service Manual for the necessary procedures. Also, refer back to the information learned earlier (see "Owner/Operator Input" section) about the truck specifications and application and judge whether or not the engine is performing as expected or customer expectation is realistic.