Information injection-pump assembly

ZEXEL

104740-8170

1047408170

Rating:

Cross reference number

ZEXEL

104740-8170

1047408170

Zexel num

Bosch num

Firm num

Name

104740-8170

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

64.8

64.3

65.3

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_02

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

65.5

65

66

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_03

Pump speed

r/min

600

600

600

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

46

43.5

48.5

Oil temperature

degC

50

48

52

Injection timing adjustment_04

Pump speed

r/min

750

750

750

Boost pressure

kPa

44

42.7

45.3

Boost pressure

mmHg

330

320

340

Average injection quantity

mm3/st.

64.8

63.8

65.8

Basic

*

Oil temperature

degC

50

48

52

Remarks

CBS

CBS

Injection timing adjustment_05

Pump speed

r/min

1000

1000

1000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

73

73

73

Oil temperature

degC

50

48

52

Injection timing adjustment_06

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

69.2

66.7

71.7

Oil temperature

degC

50

48

52

Injection timing adjustment_07

Pump speed

r/min

2000

2000

2000

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

65.5

64.5

66.5

Difference in delivery

mm3/st.

5

Basic

*

Oil temperature

degC

50

48

52

Remarks

Full

Full

Injection timing adjustment_08

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

63.8

62.3

65.3

Oil temperature

degC

52

50

54

Injection quantity adjustment

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

25

22

28

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

55

52

58

Injection quantity adjustment_02

Pump speed

r/min

3050

3050

3050

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

5

Oil temperature

degC

55

52

58

Injection quantity adjustment_03

Pump speed

r/min

2650

2650

2650

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

25

20

30

Difference in delivery

mm3/st.

5.5

Basic

*

Oil temperature

degC

55

52

58

Governor adjustment

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12

10.5

13.5

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_02

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

12

10

14

Difference in delivery

mm3/st.

2

Basic

*

Oil temperature

degC

48

46

50

Governor adjustment_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

3

Oil temperature

degC

50

48

52

Timer adjustment

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

63

63

83

Basic

*

Oil temperature

degC

48

46

50

Remarks

IDLE

IDLE

Timer adjustment_02

Pump speed

r/min

100

100

100

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

63

63

83

Oil temperature

degC

48

46

50

Speed control lever angle

Pump speed

r/min

375

375

375

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Average injection quantity

mm3/st.

0

0

0

Oil temperature

degC

48

46

50

Remarks

Magnet OFF at idling position

Magnet OFF at idling position

0000000901

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Overflow quantity

cm3/min

420

290

550

Oil temperature

degC

50

48

52

Stop lever angle

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

471

442

500

Pressure

kgf/cm2

4.8

4.5

5.1

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_02

Pump speed

r/min

600

600

600

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

314

275

353

Pressure

kgf/cm2

3.2

2.8

3.6

Oil temperature

degC

50

48

52

Stop lever angle_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

471

432

510

Pressure

kgf/cm2

4.8

4.4

5.2

Basic

*

Oil temperature

degC

50

48

52

Stop lever angle_04

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Pressure

kPa

667

628

706

Pressure

kgf/cm2

6.8

6.4

7.2

Oil temperature

degC

52

50

54

0000001101

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.7

3.5

3.9

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

500

500

500

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

1.2

0.6

1.8

Oil temperature

degC

48

46

50

_03

Pump speed

r/min

750

750

750

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

2

1.4

2.6

Oil temperature

degC

50

48

52

_04

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

3.7

3.3

4.1

Basic

*

Oil temperature

degC

50

48

52

_05

Pump speed

r/min

1750

1750

1750

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

5.8

5.2

6.4

Oil temperature

degC

50

48

52

_06

Pump speed

r/min

2100

2100

2100

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

7.2

6.6

7.8

Oil temperature

degC

52

50

54

_07

Pump speed

r/min

2250

2250

2250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Timer stroke

mm

7.8

7.4

8.2

Oil temperature

degC

52

50

54

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

0000001401

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

53

52.5

53.5

Timer stroke TA

mm

3.1

3.1

3.1

Timer stroke variation dT

mm

0.6

0.4

0.8

Basic

*

Oil temperature

degC

50

48

52

_02

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

53

52

54

Timer stroke variation dT

mm

0.6

0.2

1

Basic

*

Oil temperature

degC

50

48

52

_03

Pump speed

r/min

1250

1250

1250

Boost pressure

kPa

73.3

72

74.6

Boost pressure

mmHg

550

540

560

Average injection quantity

mm3/st.

40

39

41

Timer stroke variation dT

mm

1.4

0.9

1.9

Oil temperature

degC

50

48

52

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

0.7

0.6

0.8

BCS stroke

mm

6.5

6.4

6.6

Control lever angle alpha

deg.

59

55

63

Control lever angle beta

deg.

42

37

47

Test data Ex:

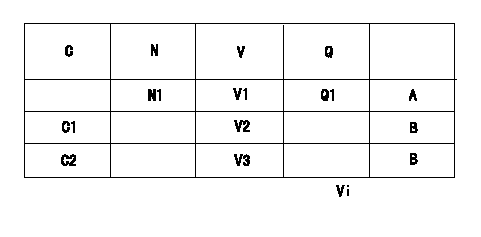

0000001801 POTENTIOMETER ADJUSTMENT

Adjustment of the potentiometer

Dummy bolt method

1. Hold the dummy bolt against the control lever at position N = N1 and Q = Q1 and fix using the lock nut.

2. At potentiometer adjustment, with the control lever contacting the dummy bolt, adjust the potentiometer so that the output voltage is V1.

3. After adjustment, remove the dummy bolt and confirm that the potentiometer output voltage at the control lever's idling and full speed positions is as specified above.

N:Pump speed

P:Boost pressure

Q:Injection quantity

V:Output voltage

A:Adjusting point

B:Checking point

C/L: control lever position

I:Idling

F:Full speed

Vi:Applied voltage

----------

----------

N1=750(r/min) V1=5+-0.03(V) V2=1++(V) V3=(8.6(V)) Q1=35.5+-1(mm3/st) Vi=10(V)

----------

----------

N1=750(r/min) V1=5+-0.03(V) V2=1++(V) V3=(8.6(V)) Q1=35.5+-1(mm3/st) Vi=10(V)

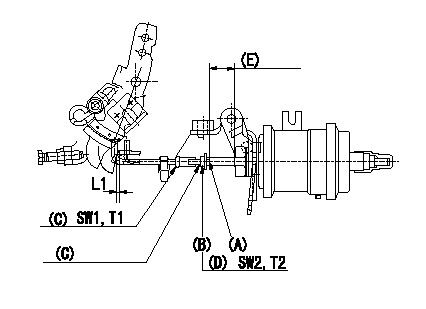

0000001901 V-FICD ADJUSTMENT

Adjustment of the two stage actuator (FICD).

1. Install the 2-stage actuator on the injection pump.

2. With the control lever in the idle position adjust using the rod position adjusting nut so that the clearance between control lever and the rod is L1.

3. After adjusting the potentiometer, fix the control lever so that the potentiometer output voltage is V1. (Applied voltage Vi)

4. Adjust the position of A so that the actuator stroke is the full stroke, then fix using nut (B).

(C) Rod position adjusting nut

(D) Stroke adjusting nut

(E) Actuator stroke

----------

L1=1+1(mm) V1=3.5+-0.03(V) Vi=10(V)

----------

L1=1+1(mm) SW1=SW7 SW2=SW8 T1=1.4~2.0(Nm)(0.14~0.2(kgfm)) T2=3.4~4.9(Nm)(0.35~0.5(kgfm))

----------

L1=1+1(mm) V1=3.5+-0.03(V) Vi=10(V)

----------

L1=1+1(mm) SW1=SW7 SW2=SW8 T1=1.4~2.0(Nm)(0.14~0.2(kgfm)) T2=3.4~4.9(Nm)(0.35~0.5(kgfm))

Information:

Start By:a. remove valve covers 1. Loosen the fuel injection line nut at the nozzle end with tool (A).2. Loosen the fuel line nut at the fuel injection line adapter with tool (B). Remove inner fuel injection lines (1). Install caps and plugs on all fuel line openings to keep dirt out of the fuel system. If necessary, use tooling (D) to turn the engine so the valves do not make contact with the pistons when the valves are opened with tool (C) to remove the push rods.3. Put compression on the valve springs with tool (C), and remove push rods (2). Put identification marks on the push rods as to their location in the engine.4. Push the push rod end of the rocker arms down. 5. Remove the intake valve lifter with tooling (E) as follows:a. Install 5P2685 Nut (3) and 5P6601 Collet (4) on 5P2408 Outer Handle Assembly (5).b. Install 5P6599 Inner Handle Assembly (6) in 5P2408 Outer Handle Assembly (5). c. Install tooling (E) in the intake valve lifter. Hold the 5P2408 Outer Handle Assembly, and tighten the 5P6599 Inner Handle Assembly until the 5P6601 Collet is tight against the inside of the intake valve lifter. d. Remove intake valve lifters (7) from the cylinder block with tooling (E). Put identification marks on the lifters as to their location in the engine. 6. Remove the exhaust valve lifters with tooling (E) as follows:a. Install 5P2685 Nut (3) and 5P6601 Collet (4) on 5P2408 Outer Handle Assembly (5). The opening in the cylinder head assembly for the intake valve lifter is larger than the opening in the exhaust valve lifter side. The tooling and each valve lifter must be installed and removed from the intake valve lifter side.b. Install the outer handle assembly in the intake valve lifter side of the cylinder head assembly. Slide the flat area of 5P2408 Outer Handle Assembly (5) through the head casting, and install the 5P6601 Collet in the exhaust valve lifters. c. Install 5P6599 Inner Handle Assembly (6) in 5P2408 Outer Handle Assembly (5). Hold the 5P2408 Handle Assembly, and tighten the 5P6599 Handle Assembly until the 5P6601 Collet is tight against the inside of the exhaust valve lifter.d. Pull the exhaust valve lifter up until the spring on the exhaust valve lifter is free from the cylinder block.e. Remove the 5P6599 Inner Handle Assembly. Slide the 5P2408 Outer Handle Assembly through the head casting, and remove it from the intake valve lifter side of the cylinder head. f. Use a magnet, and remove exhaust valve lifters (8) from the intake valve lifter side of the cylinder head assembly. Put identification marks on the lifters as to their location in the engine.7. Remove the guide springs from the lifters.Install Valve Lifters

Steps 1 and 2 must be done to install intake or exhaust valve lifters.

Make sure guide spring (9) is not damaged or worn. If the guide spring is damaged or worn, replace the guide spring. See Guideline For Reusable

Steps 1 and 2 must be done to install intake or exhaust valve lifters.

Make sure guide spring (9) is not damaged or worn. If the guide spring is damaged or worn, replace the guide spring. See Guideline For Reusable

Have questions with 104740-8170?

Group cross 104740-8170 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

104740-8170

INJECTION-PUMP ASSEMBLY