Information injection-pump assembly

BOSCH

9 460 614 312

9460614312

ZEXEL

104740-7660

1047407660

NISSAN-DIESEL

1670021T17

1670021t17

Rating:

Cross reference number

BOSCH

9 460 614 312

9460614312

ZEXEL

104740-7660

1047407660

NISSAN-DIESEL

1670021T17

1670021t17

Zexel num

Bosch num

Firm num

Name

104740-7660

9 460 614 312

1670021T17 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

TD25 * K

TD25 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105000-2010

Bosch type code

NP-DN12SD12TT

Nozzle holder

105780-2080

Opening pressure

MPa

14.7

14.7

15.19

Opening pressure

kgf/cm2

150

150

155

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-840

Inside diameter - outside diameter - length (mm) mm 2-6-840

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

(Solenoid timer adjustment condition)

OFF

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

45.8

45.3

46.3

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

12.1

9.6

14.6

Injection timing adjustment_03

Pump speed

r/min

2300

2300

2300

Average injection quantity

mm3/st.

32.8

28.3

37.3

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

37.9

35.8

40

Injection timing adjustment_05

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

45.8

44.8

46.8

Injection timing adjustment_06

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

44.4

42.4

46.4

Injection quantity adjustment

Pump speed

r/min

2500

2500

2500

Average injection quantity

mm3/st.

12.1

10.1

14.1

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

6.5

4.5

8.5

Governor adjustment_03

Pump speed

r/min

450

450

450

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

62.5

45

80

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

390

258

522

_02

Pump speed

r/min

1100

1100

1100

Overflow quantity with S/T ON

cm3/min

489

360

618

Remarks

Without an O-ring

Without an O-ring

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure with S/T ON

kPa

480.5

441

520

Pressure with S/T ON

kgf/cm2

4.9

4.5

5.3

Pressure with S/T OFF

kPa

372.5

343

402

Pressure with S/T OFF

kgf/cm2

3.8

3.5

4.1

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure with S/T OFF

kPa

510

481

539

Pressure with S/T OFF

kgf/cm2

5.2

4.9

5.5

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure with S/T OFF

kPa

598.5

569

628

Pressure with S/T OFF

kgf/cm2

6.1

5.8

6.4

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.3

3.9

4.7

Timer stroke with S/T OFF

mm

2.6

2.4

2.8

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke with S/T ON

mm

4.3

3.8

4.8

Timer stroke with S/T OFF

mm

2.6

2.3

2.9

_03

Pump speed

r/min

1700

1700

1700

Timer stroke with S/T OFF

mm

4.9

4.3

5.5

_04

Pump speed

r/min

2300

2300

2300

Timer stroke with S/T OFF

mm

6.5

6

7

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.8

5.7

5.9

MS dimension

mm

1

0.9

1.1

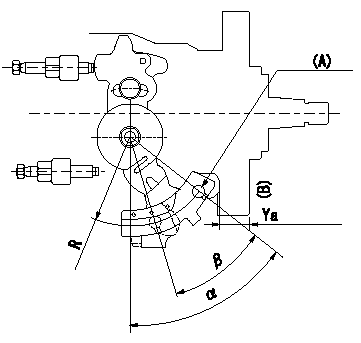

Control lever angle alpha

deg.

54

50

58

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension L between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle measuring position

(B) = flange face

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

----------

L=10.7~14.2mm R=49mm

Information:

Start By:a. remove cylinder headb. remove oil panc. remove cooling jets 1. Remove two rod cap bolts (1) from each rod. Remove rod caps (2).2. Using a soft hammer tape rod (3) away from crankshaft and remove bearing half (4). When removing cylinder pack, watch the rod and prevent it from catching on the block bore as it comes out.3. Install tooling (A) and remove cylinder pack (5). 4. Remove cylinder liner seal (6) at the base of the spacer block. 5. Remove the remainder of tooling (A) from cylinder pack (5) and then remove the rod and piston from the cylinder liner. The following steps are for the installation of the cylinder pack.6. Install a new cylinder liner seal, lubricate the seal with engine oil. Some engines use pistons which have the word "FRONT" stamped on the crown of the piston. Make sure the word "FRONT" is toward the front of the engine when the piston is installed. The etched number on the connecting rod must be on the right side and must be installed in the corresponding cylinder. 9U-5839 Liquid Gasket Material is applied to the cylinder liners in the area shown in the illustration. The liquid gasket material helps prevent oil leaks from between the cylinder block and spacer block. DO NOT apply any 9U-5839 Liquid Gasket Material between the engine spacer block and the cylinder block surfaces. Using excessive amounts of liquid gasket material on the liner flange seat can cause oil leaks due to distortion of the O-ring seals between the spacer block and cylinder block.7. Lubricate the lower portion of the cylinder liner with engine oil. Be sure the corresponding crankshaft throw is at bottom center. Position cylinder pack (5) and guide rod (3) into place. Use tooling (B) and press cylinder pack (5) into place.8. With rod (3) in this position, install the upper half of rod bearing (4). Be sure the bearing tab properly engages the slot in the connecting rod. Lubricate the bearing surface with engine oil and tap the piston down with a rubber mallet until the rod and bearing contacts the crankshaft.9. With rod cap bearing in place and oiled, install rod cap (2). Lubricate rod bolts (1) with 2P2506 Thread Lubricant. Install rod bolts (1) and torque to 130 7 N m (95 5 lb.ft.). Mark each bolt head and then tighten each bolt an additional 60 5° (1/6 turn).End By:a. install cooling jets.b. install oil pan.c. install cylinder head.

Have questions with 104740-7660?

Group cross 104740-7660 ZEXEL

Dpico

Nissan-Diesel

Dpico

Nissan-Diesel

104740-7660

9 460 614 312

1670021T17

INJECTION-PUMP ASSEMBLY

TD25

TD25