Information injection-pump assembly

ZEXEL

104740-7142

1047407142

NISSAN-DIESEL

1670080G12

1670080g12

Rating:

Cross reference number

ZEXEL

104740-7142

1047407142

NISSAN-DIESEL

1670080G12

1670080g12

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113orSAEJ967d

1404 Test oil ISO4113orSAEJ967d

Test oil temperature

degC

45

45

50

Nozzle

105780-0060

Bosch type code

NP-DN0SD1510

Nozzle holder

105780-2150

Opening pressure

MPa

13

13

13.3

Opening pressure

kgf/cm2

133

133

136

Injection pipe

157805-7320

Injection pipe

Inside diameter - outside diameter - length (mm) mm 2-6-450

Inside diameter - outside diameter - length (mm) mm 2-6-450

Joint assembly

157641-4720

Tube assembly

157641-4020

Transfer pump pressure

kPa

20

20

20

Transfer pump pressure

kgf/cm2

0.2

0.2

0.2

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52

51.5

52.5

Difference in delivery

mm3/st.

3

Basic

*

Injection timing adjustment_02

Pump speed

r/min

2550

2550

2550

Average injection quantity

mm3/st.

12.6

8.1

17.1

Injection timing adjustment_03

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

35.2

32.7

37.7

Injection timing adjustment_04

Pump speed

r/min

2150

2150

2150

Average injection quantity

mm3/st.

46.3

43.8

48.8

Injection timing adjustment_05

Pump speed

r/min

2000

2000

2000

Average injection quantity

mm3/st.

49.1

46.1

52.1

Injection timing adjustment_06

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

52.3

51.3

53.3

Injection timing adjustment_07

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

53.2

50.7

55.7

Injection timing adjustment_08

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

51.2

48.7

53.7

Injection quantity adjustment

Pump speed

r/min

2400

2400

2400

Average injection quantity

mm3/st.

35

33

37

Basic

*

Injection quantity adjustment_02

Pump speed

r/min

2700

2700

2700

Average injection quantity

mm3/st.

5

Governor adjustment

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.3

7.3

11.3

Difference in delivery

mm3/st.

2

Basic

*

Governor adjustment_02

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

9.3

7.3

11.3

Governor adjustment_03

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

3

Timer adjustment

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

75

60

90

Basic

*

Speed control lever angle

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

0

0

0

Remarks

Magnet OFF

Magnet OFF

0000000901

Pump speed

r/min

1100

1100

1100

Overflow quantity

cm3/min

390

258

522

Stop lever angle

Pump speed

r/min

1100

1100

1100

Pressure

kPa

490.5

461

520

Pressure

kgf/cm2

5

4.7

5.3

Basic

*

Stop lever angle_02

Pump speed

r/min

1100

1100

1100

Pressure

kPa

490.5

461

520

Pressure

kgf/cm2

5

4.7

5.3

Stop lever angle_03

Pump speed

r/min

1700

1700

1700

Pressure

kPa

666.5

637

696

Pressure

kgf/cm2

6.8

6.5

7.1

Stop lever angle_04

Pump speed

r/min

2150

2150

2150

Pressure

kPa

764.5

735

794

Pressure

kgf/cm2

7.8

7.5

8.1

0000001101

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

3.8

3.6

4

Basic

*

_02

Pump speed

r/min

1100

1100

1100

Timer stroke

mm

3.8

3.6

4

_03

Pump speed

r/min

1700

1700

1700

Timer stroke

mm

6.5

6.1

6.9

_04

Pump speed

r/min

2250

2250

2250

Timer stroke

mm

8.55

8.1

9

0000001201

Max. applied voltage

V

8

8

8

Test voltage

V

13

12

14

Timing setting

K dimension

mm

3.3

3.2

3.4

KF dimension

mm

5.82

5.72

5.92

MS dimension

mm

0.9

0.8

1

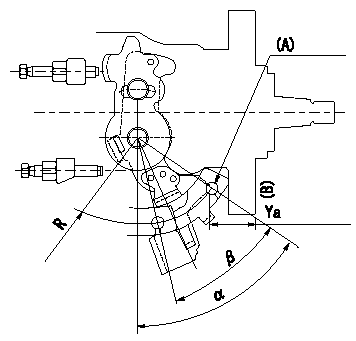

Control lever angle alpha

deg.

55.5

51.5

59.5

Control lever angle beta

deg.

36

31

41

Test data Ex:

0000001801 CONTROL LEVER ANGLE

Control lever angle measurement

1. Measure dimension Ya between the end of the lever and the flange face.

2. Measure the lever angle from the pin hole R (plate).

(A) = lever angle and lever reaction force measuring position

----------

Ya=24.3~28.7mm R=53mm

----------

Ya=24.3~28.7mm R=53mm Alpha=51.5~59.5deg Beta=31~41deg

----------

Ya=24.3~28.7mm R=53mm

----------

Ya=24.3~28.7mm R=53mm Alpha=51.5~59.5deg Beta=31~41deg

Information:

Connect the wiring harness to a voltage source of 12 VOLTS maximum with a negative ground only. Install the additive tank on the outside of the engine compartment.

Connect the wiring to 8L5000 Switch (1) so that the system can be activated with the starting motor switch in the OFF position. Keep the additive tank full when not in use. This will prevent damage to the system and components by corrosion when not used for long periods of time.Operation: Just before the engine is started, push the switch to activate the system; this will let the additive flow for approximately two minutes, through an orifice connected to the fuel supply line of the Sleeve Metering Fuel System. The fuel transfer pump then pulls the additive into the system along with the Diesel fuel. The system can be again activated if necessary. The engine can be started approximately three to four times per liter (fifteen to twenty times per gallon) of additive.Maintenance: Keep the additive tank full when not in use. This will prevent damage to the system and components by corrosion when not used for long periods of time. Install a new injection group filter (9N3778) at six month intervals or when the filter becomes plugged (full of foreign material) so additive will not flow through it. ADDITIVE RECOMMENDATION: Ethyl D112 Diesel Ignition Improver AVAILABLE SOURCE:U.S.A.

Ethyl Corporation

Distribution Service

Petroleum Chemical Division

451 Florida Boulevard

Baton Rouge, Lousiana 70801

CANADA

Ethyl Corporation of Canada, Ltd.

48 St. Clair Avenue West

Toronto, Ontario, Canada M4V1M7

Order Department

Ethyl D11-2 Diesel Ignition Improver is highly flammable; do not install the additive tank near a source of heat or sparks. If there is a leak in the tank or an accident causes a loss of additive, a fire could be the result.

1 - 9N3334 Tank Assembly2 - 1P4022 Fitting3 - 9N3778 Filter Assembly4 - 8L6557 Connector5 - 317224 Hose Assembly6 - 306984 Connector7 - 9L8791 Solenoid8 - 7W1539 Orifice9 - 8T2543 Tee10 - 5P5009 Reducer11 - 9N3828 Harness Assembly12 - 7G1018 Relay13 - 8L5000 Switch14 - 9N3335 Strap 533567 Bracket15 - 5P0733 Hose 200 (8.0")16 - 1P4278 Clamp17 - 7D1553 Clip18 - 8J1256 Clip19 - 4B1248 Screw 4B2051 Nut 4B4674 Washer20 - 3J7354 Seal21 - 1J9671 Seal1 Install items (12) and (13) inside the operator's compartment; fasten switch (13) on the dash and install relay (12) under the dash. Install additive tank (1) on the outside of the engine compartment in an acceptable location for easy access and away from any source of heat.2 Install 9N3620 Fuel Additive Injection Instruction Film on the dash next to 8L5000 Switch (13). Install 9N3621 CAUTION Film on tank (1) at a location that can be seen from the side of the vehicle.3 Install the remainder of the parts as shown in the above illustration. Fasten filter (3), and hoses (5) and (15) with the clips shown.4 Check the system for leaks after the installation is complete; use air at a maximum pressure of 70 to 105 kPa (10 to 15 psi).